Sizing frame after pipeline forming

A pipeline and water inlet pipe technology, applied in the field of setting frame, can solve the problems of long time required, inconvenient transportation and construction, insufficient strength, etc., and achieve the effects of convenient storage work, shortened setting time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

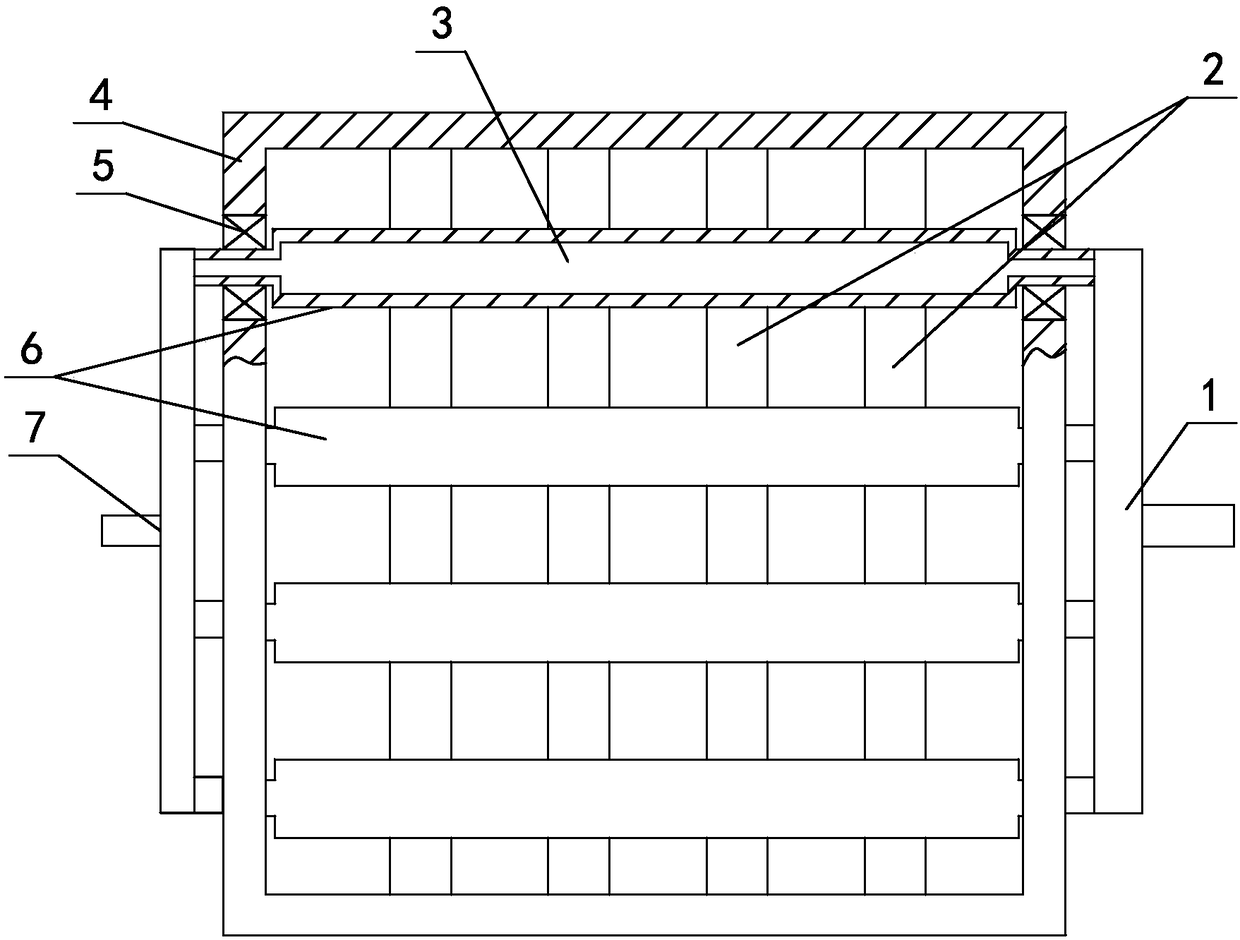

[0017] Such as figure 1 As shown, the calibrating frame after the pipeline is formed includes a frame support 4, on which a plurality of heat exchange rollers 6 that are freely rotating and arranged in parallel at equal intervals front and back are arranged, and the two ends of the heat exchange rollers 6 pass through the bearings 5 Installed on the frame support 4, each heat exchange roller 6 is provided with an exchange chamber 3, and on the right side of the frame support 4 is provided with a water inlet pipe 1, and the water inlet pipe 1 is connected to the right end of each heat exchange roller 6 and communicated with the exchange chamber 3 A water outlet pipe 7 is arranged on the left side of the frame bracket 4, and the water outlet pipe 7 is connected to the left end of each heat exchange roller 6 and communicated with the exchange chamber 3.

[0018] In this embodiment, the distance between the adjacent heat exchange rollers 6 is 10 cm; under the heat exchange rollers...

Embodiment 2

[0021] Based on the first embodiment, the distance between the adjacent heat exchange rollers 6 is 20 cm; the distance between the adjacent reinforcing rods 2 is 40 cm.

[0022] Others are the same as embodiment one.

Embodiment 3

[0024] Based on the first embodiment, the distance between the adjacent heat exchange rollers 6 is 30 cm; the distance between the adjacent reinforcing rods 2 is 50 cm.

[0025] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com