Roller hot press molding manufacturing method of shoe outsole

A manufacturing method, hot-press molding technology, applied in the direction of household components, applications, coatings, etc., can solve the problems of limiting the application of TPU and high production costs, and achieve the effects of reducing energy consumption, fast production speed, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Detailed specific embodiments of the present invention will be disclosed herein. It is to be understood, however, that the disclosed embodiments are merely typical examples of the invention, which may be embodied in many alternative forms. Therefore, specific structural and functional details disclosed herein are not limiting, but merely serve as a representative basis for describing various implementations to one skilled in the art in accordance with the claims.

[0036] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

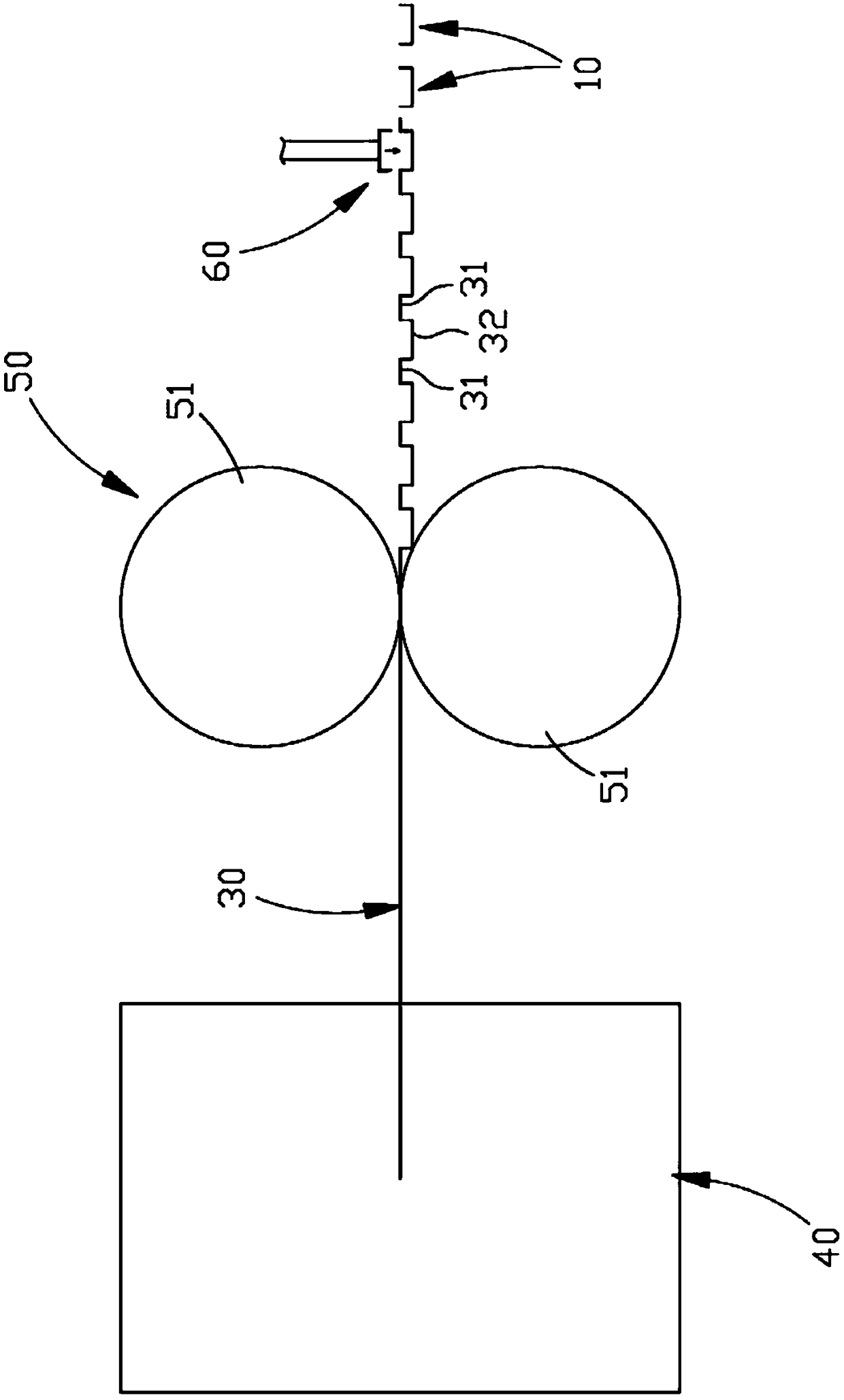

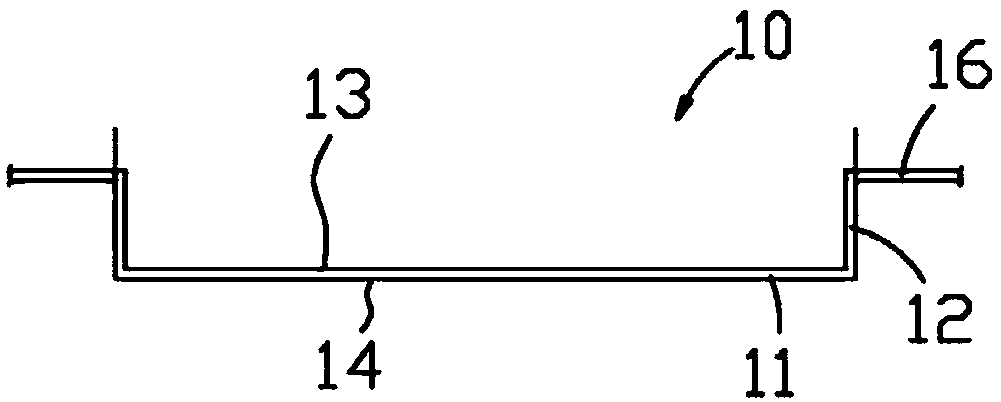

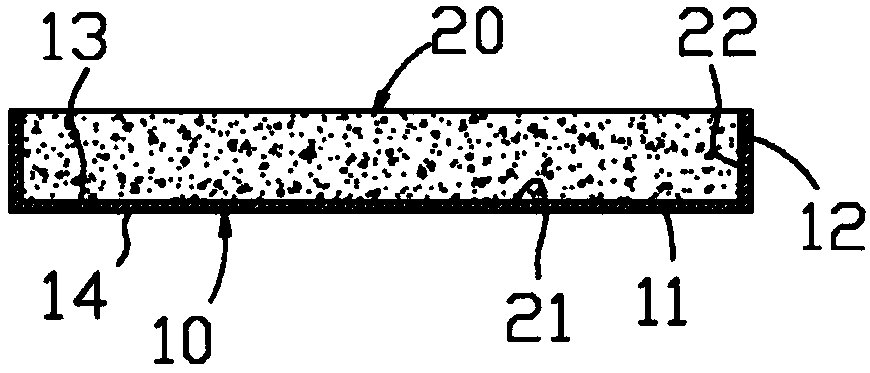

[0037] The invention provides a method for manufacturing shoe outsole rollers by hot pressing, figure 1It shows a schematic diagram of processing a TPU diaphragm 30 to form a TPU diaphragm outsole 10 according to the method of the present invention. After the TPU diaphragm 30 is output from the cast film extrusion device 40, it enters the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com