Citric acid aluminum-plastic composite packaging material separating agent as well as preparation and application method thereof

A composite packaging material, aluminum citrate technology, applied in the direction of plastic recycling, recycling technology, process efficiency improvement, etc., can solve the problems of high volatility of the separating agent, human and atmospheric hazards, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

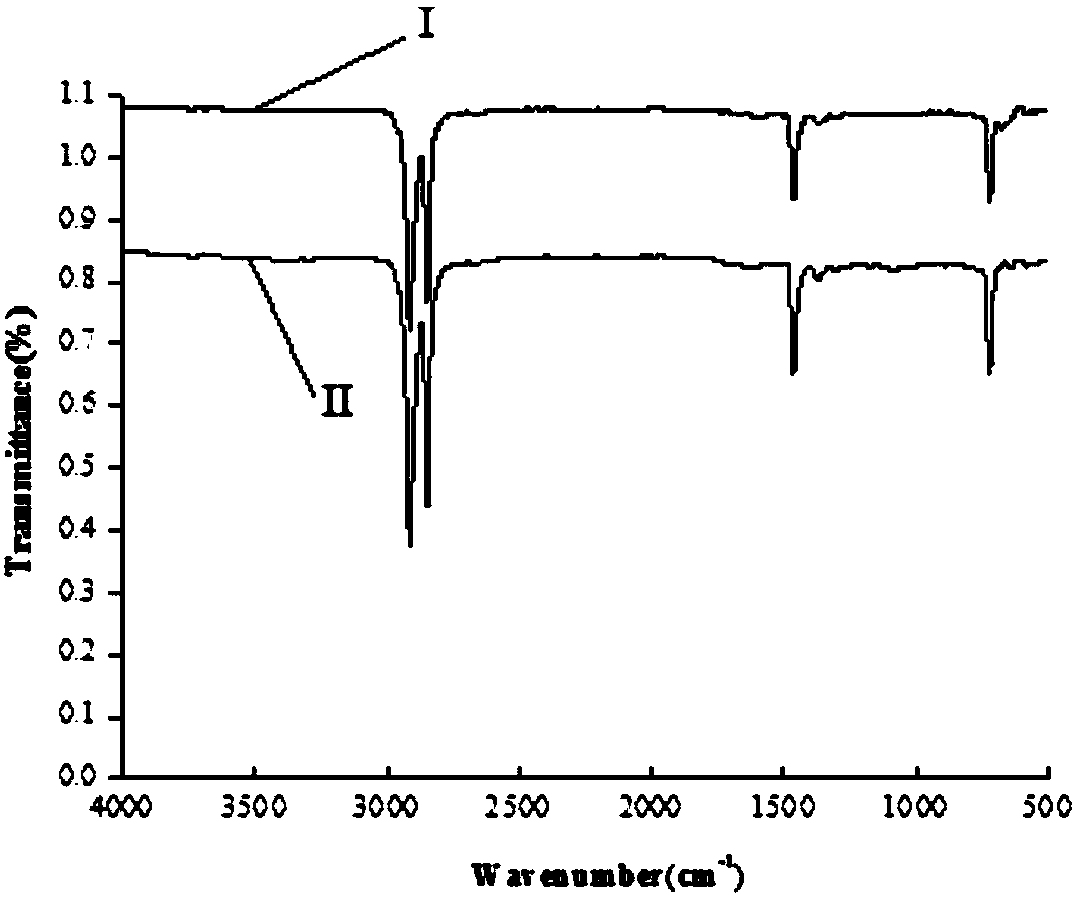

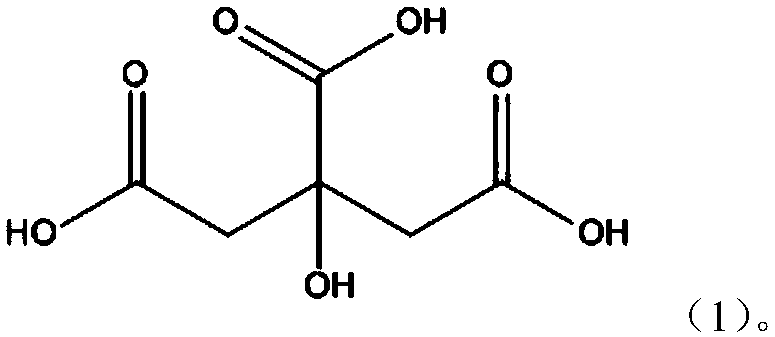

[0035] A citrate-aluminum-plastic composite packaging material separating agent in this embodiment is a citric acid solution prepared at a concentration of 3 mol / L at 85° C.; wherein the solute of the citric acid solution is citric acid, and the solvent is water.

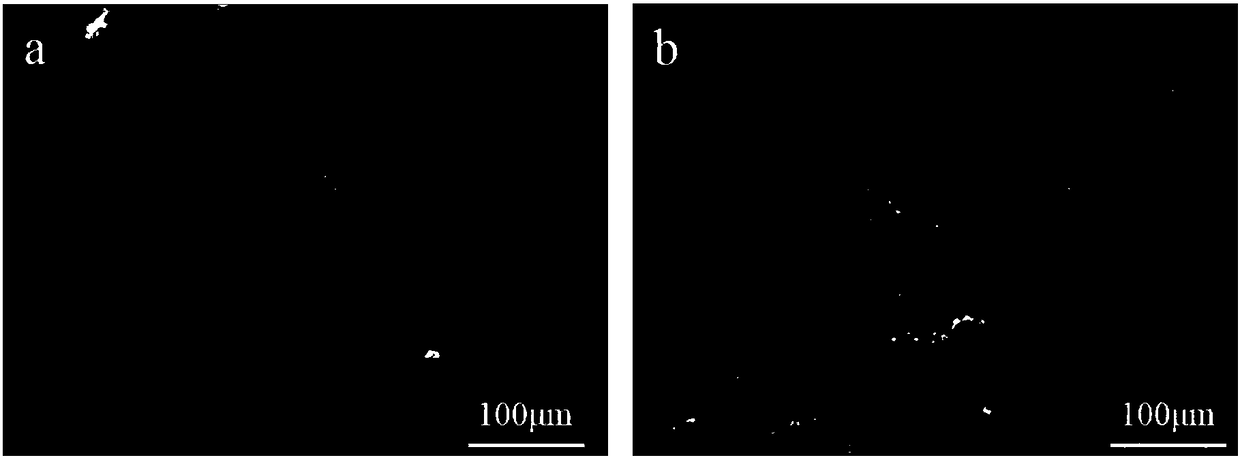

[0036] The use method of the present invention is: add 1 kg of aluminum-plastic composite packaging material into the reactor, add 3 L of separating agent, put it into a constant temperature shaking reactor at 95°C, completely separate the plastic from the aluminum foil after 420 minutes, and separate the separated plastic and Wash the aluminum foil in clean water, dry and weigh it, and calculate its recovery rate p and loss rate p 1 .

[0037] Recovery rate p and loss rate p 1 Calculated as follows:

[0038]

[0039] p 1 =1-p

[0040] Among them, p is the recycling rate of aluminum and plastic; m 0 is the mass of aluminum-plastic before reaction; m 1 is the mass of aluminum foil after reaction; m 2 is the...

Embodiment 2

[0043] A citric acid separating agent for aluminum-plastic composite packaging materials in this embodiment is a citric acid solution with a concentration of 4 mol / L prepared at 88° C., wherein the solute of the citric acid solution is citric acid, and the solvent is water.

[0044] The method of use of the present invention is as follows: add 1kg of aluminum-plastic composite packaging material into the reactor, add 5L of separating agent, put it into a constant temperature oscillating reactor at 90°C, and after 387 minutes, the plastic and aluminum foil are completely separated, and the separated plastic and Wash the aluminum foil in clean water, dry and weigh it, and calculate its recovery rate p and loss rate p 1 .

[0045] Recovery rate p and loss rate p 1 Calculated as follows:

[0046]

[0047] p 1 =1-p

[0048] Among them, p is the recycling rate of aluminum and plastic; m 0is the mass of aluminum-plastic before reaction; m 1 is the mass of aluminum foil after...

Embodiment 3

[0051] A citric acid separating agent for aluminum-plastic composite packaging materials in this embodiment is a citric acid solution with a concentration of 5 mol / L prepared at 92° C., wherein the solute of the citric acid solution is citric acid, and the solvent is water.

[0052] The method of use of the present invention is: add 1 kg of aluminum-plastic composite packaging material into the reactor, add 8 L of separating agent, put it into a constant temperature oscillating reactor at 85°C, and after 343 minutes, the plastic and aluminum foil are completely separated, and the separated plastic and Wash the aluminum foil in clean water, dry and weigh it, and calculate its recovery rate p and loss rate p 1 .

[0053] Recovery rate p and loss rate p 1 Calculated as follows:

[0054]

[0055] p 1 =1-p

[0056] Among them, p is the recycling rate of aluminum and plastic; m 0 is the mass of aluminum-plastic before reaction; m 1 is the mass of aluminum foil after reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com