Automatic pickling system

A kind of pickling device and automatic technology, which is applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of slow pickling speed and galvanizing influence, and achieve the goal of reasonable structure and accelerated pickling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

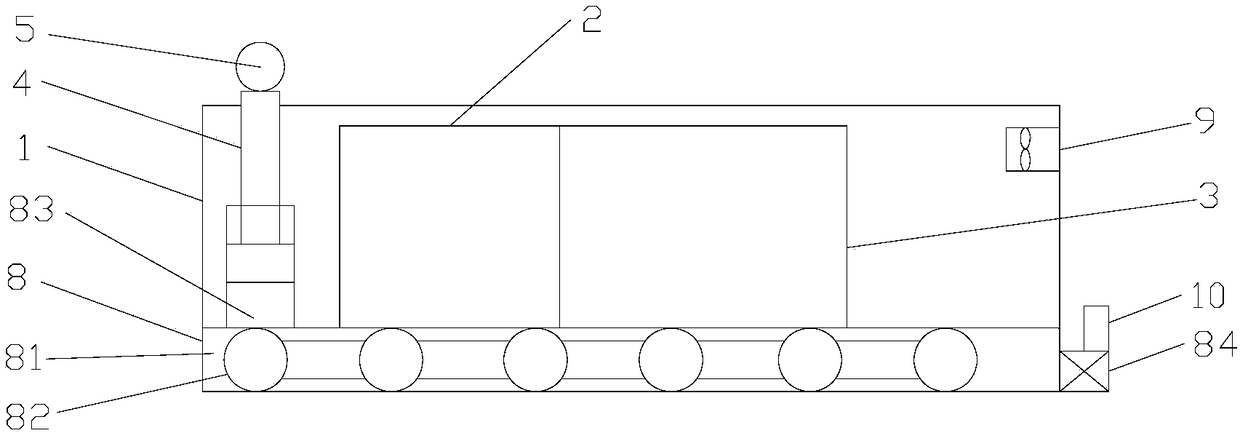

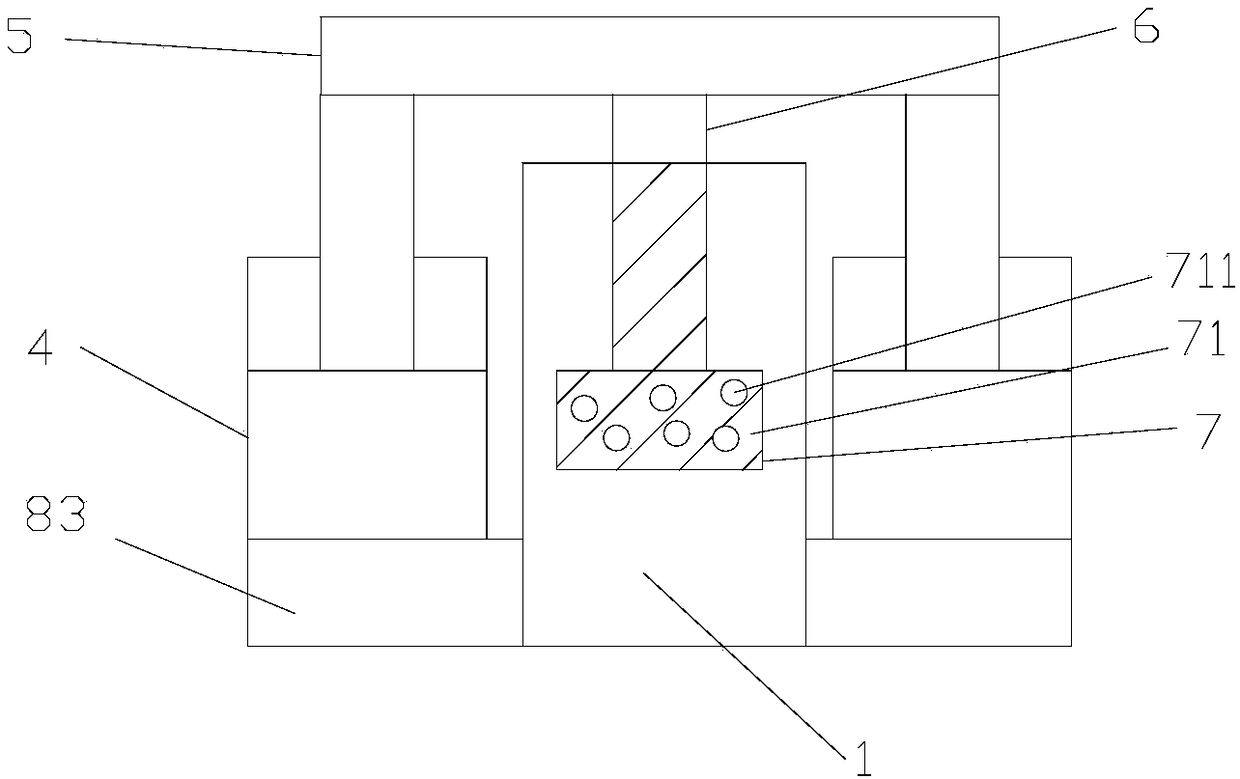

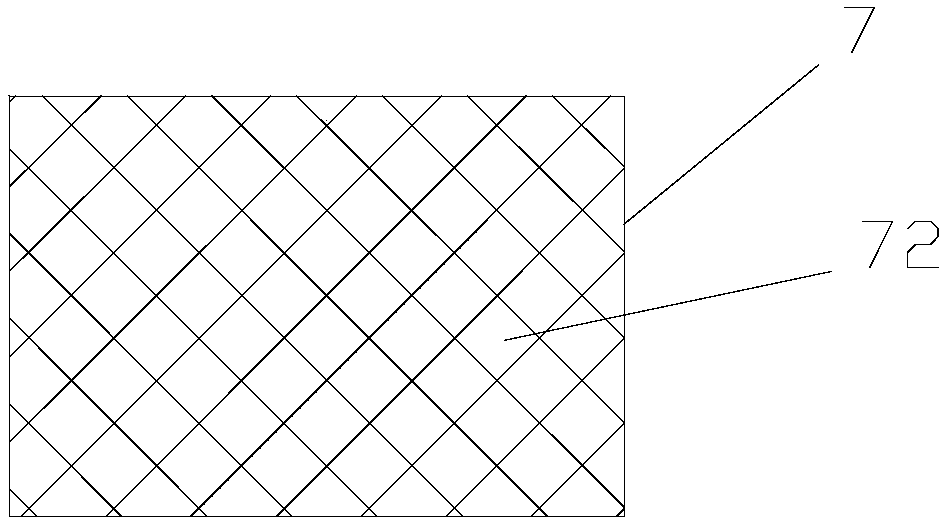

[0016] refer to figure 1 , figure 2 and image 3 , the embodiment of the present invention provides an automatic pickling device, including a heating water tank 1, a pickling tank 2, a water washing tank 3, a cylinder 4, a fixed shaft 5, a support shaft 6, a cleaning tank 7, a transportation device 8, and a fan 9. The inside of the heating water tank 1 is provided with a pickling tank 2 and a water washing tank 3, the pickling tank 2 is on the left side of the water washing tank 3, the cylinder 4 has two, and the piston rod of the cylinder 4 is connected with a fixed shaft 5, the cylinder 4 is at both ends of the fixed shaft 5, the bottom of the fixed shaft 5 is fixed with a support shaft 6, the fixed shaft 5 is vertically connected with the support shaft 6, and the bottom of the support shaft 6 is connected with a cleaning Tank 7, the transport device 8 has two sets, the transport device 8 is fixed on the outer wall of the hot water tank 1, the side of the hot water tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com