Super-hydrophobic corrosion-resistant composite tile and method for manufacturing same

A corrosion-resistant and super-hydrophobic technology, applied in the direction of roofing, roofing, and buildings using tile/slate, it can solve the problems of short service life, weak waterproof and corrosion resistance, and complicated cement tile construction, so as to enhance corrosion resistance. properties, prolonging service life, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The purpose of the present invention can be achieved through the following technical solutions:

[0026] The present invention by modifying nano-SiO 2 Bonding on the surface of fluorine-containing polyurethane with low surface energy forms a rough structure to form a super-hydrophobic surface material, and then produces super-hydrophobic and corrosion-resistant composite tiles through coating and coating processes.

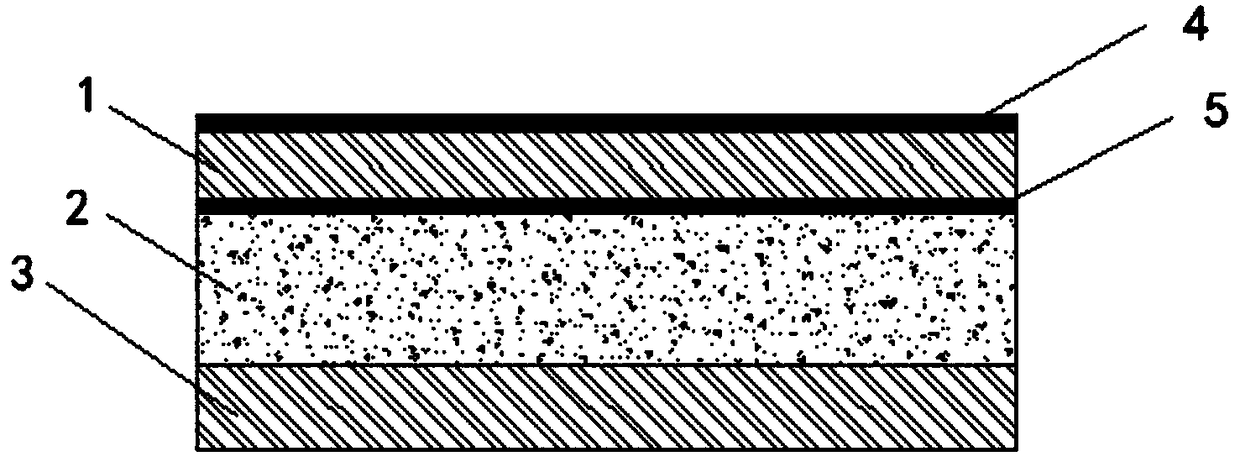

[0027] A kind of superhydrophobic corrosion-resistant composite tile, see figure 1 , including color steel surface layer 1, polyurethane foam core 2, color steel bottom layer 3, top hydrophobic layer 4, bottom hydrophobic layer 5;

[0028] The upper surface and the lower surface of the color steel surface layer 1 cover the top hydrophobic layer 4 and the bottom hydrophobic layer 5 respectively, and the top surface of the polyurethane foam core 2 is pasted below the bottom hydrophobic layer 5, and the bottom surface of the polyurethane foam core 2 is pasted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com