Concrete distribution system and construction method in track-type floors

A distribution system and concrete technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of low construction efficiency and high labor intensity, and achieve the effect of continuous distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

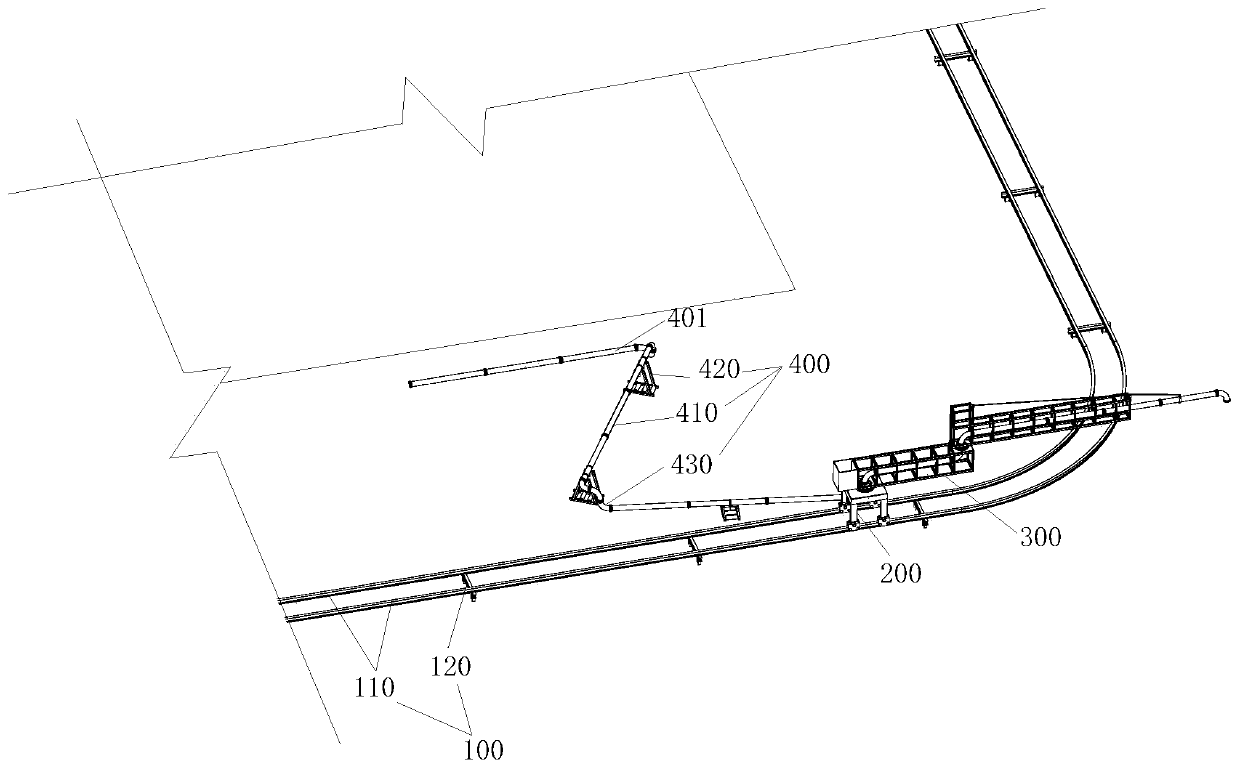

[0053] This embodiment provides a construction method for a concrete distribution system in a rail-type floor, combining Figure 1 to Figure 6 The construction method is further introduced, specifically including the following steps:

[0054] S1. If Image 6 As shown, according to the size of the core tube and the area of the floor slab, determine the layout quantity of the fixed pump pipe 401, the outlet position and the length of the rotating distribution pipe 320, and then install the track assembly 100, the pump pipe follower mechanism 400, the traveling mechanism 200 and the rotary distribution pipe. The mechanism 300 constitutes the track-type concrete distribution system in the floor as in the first embodiment. According to the length of the pump pipe follower mechanism 400 and the radius of the rotary distribution mechanism 300, it can be calculated that three fixed pump pipe 401 outlets are arranged around the core tube to complete the concrete distribution in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com