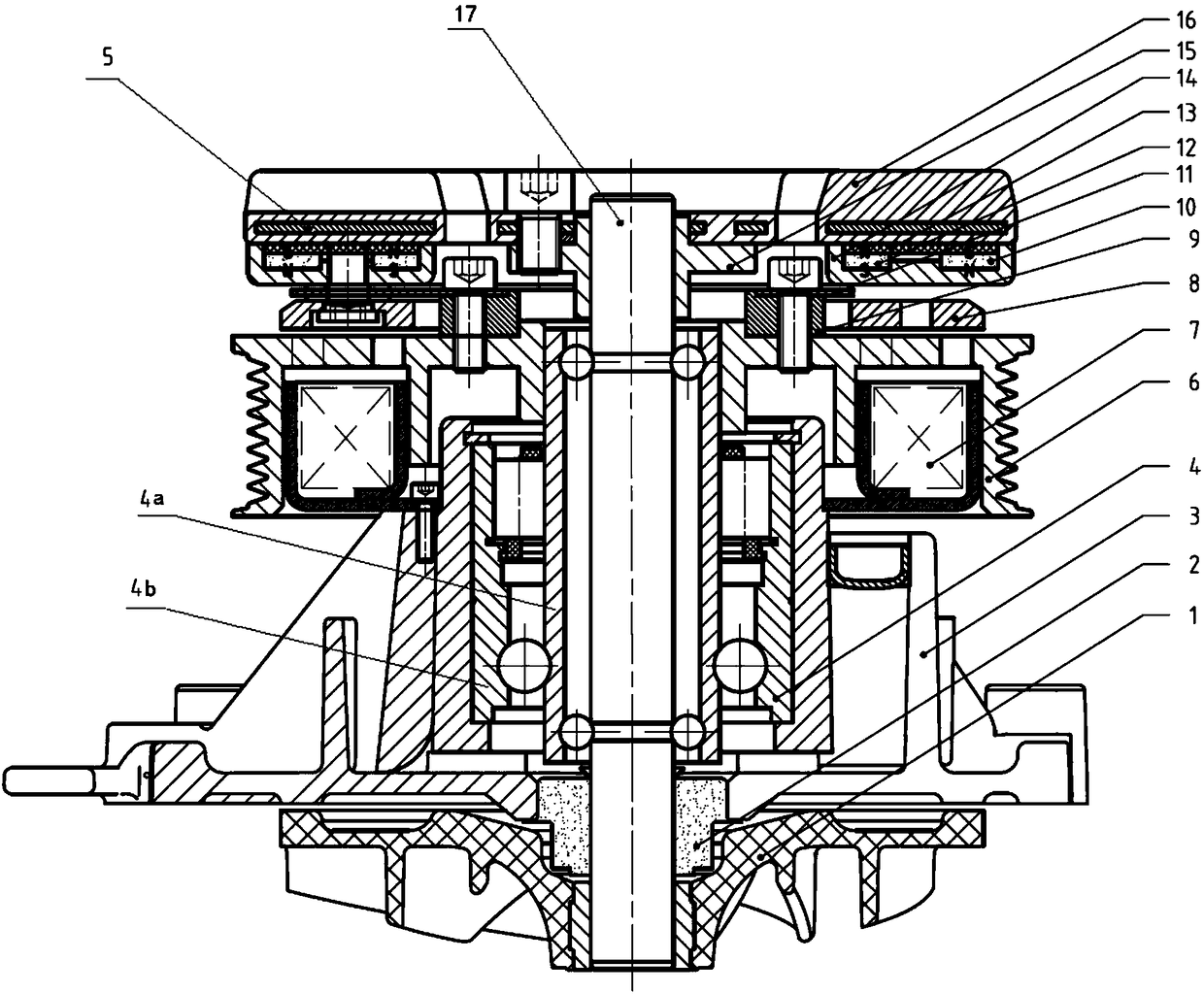

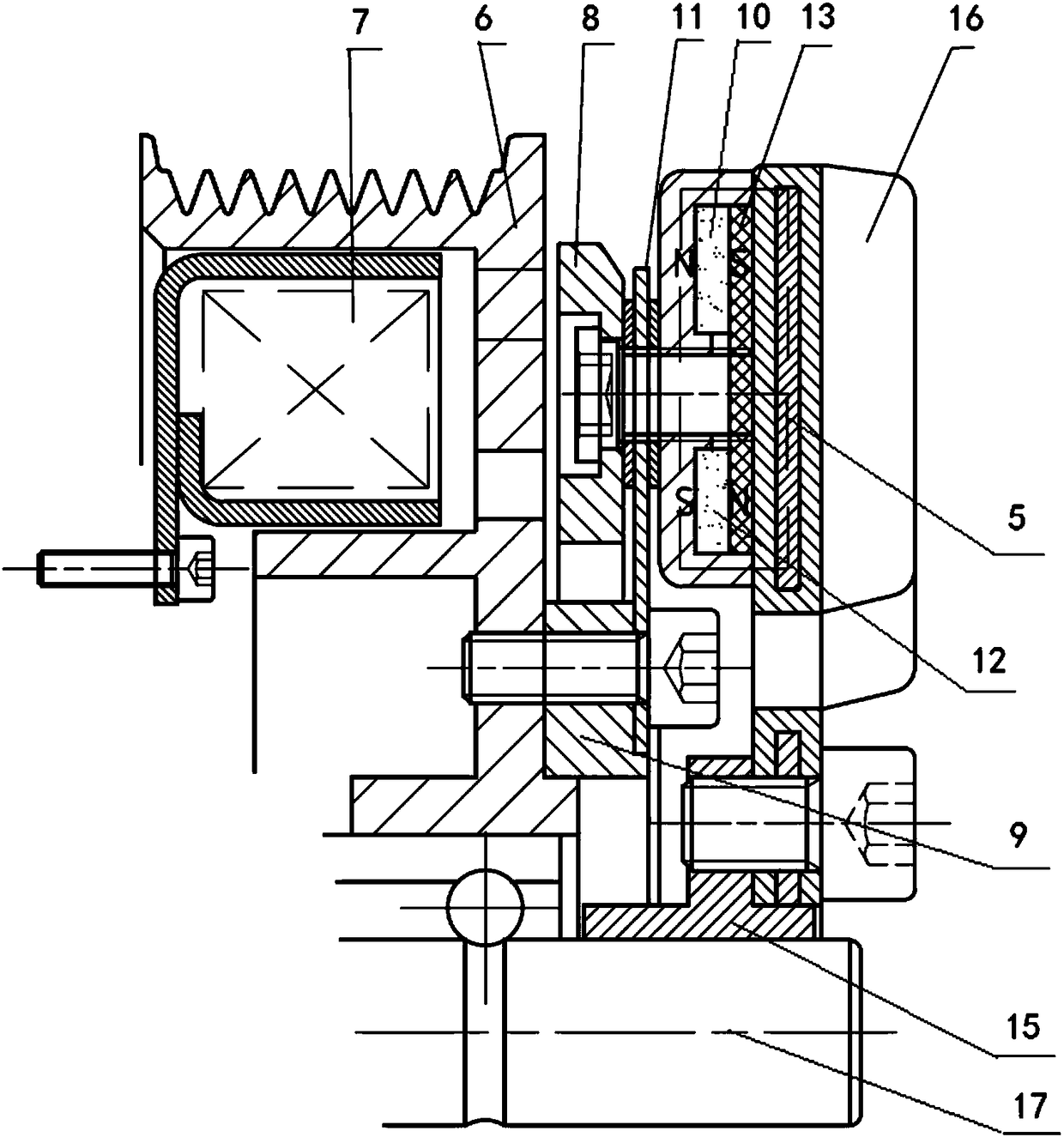

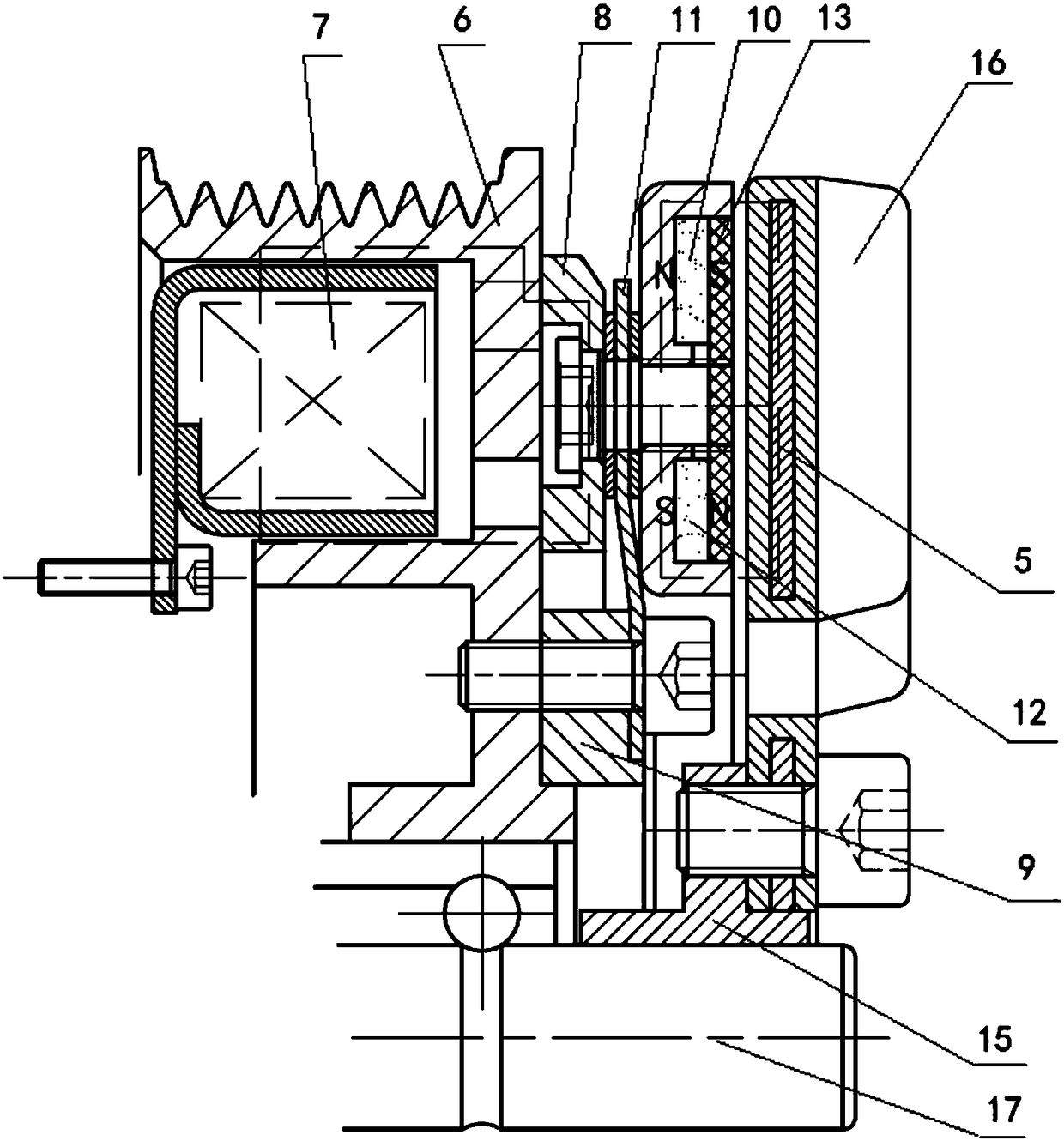

Electromagnetic clutch water pump with dual friction disks

An electromagnetic clutch, friction disc technology, applied in the direction of magnetic drive clutch, clutch, non-mechanical drive clutch, etc., can solve the problems of unreliability of torque transmission, low reliability and stability, safety problems, etc. Stability, good work reliability, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example: Combined Figure 1~Figure 3 As shown, the electromagnetic clutch water pump with double friction discs provided by the present invention is described in detail as follows: it is the same as the conventional technology, and has a main shaft 17 that passes through the pump body 3, and the main shaft 17 stretches out from both ends of the pump body 3, and one end The impeller 1 is fixed, and the other end is sequentially sleeved with a pulley suction cup 6 and a metal friction disk 8 . The pulley suction cup 6 is provided with an electromagnetic coil assembly 7 , and the metal friction disk 8 and the pulley suction cup 6 are arranged with a gap between them.

[0038] The main improvement of the present invention is as follows: the side of the metal friction disc 8 facing away from the pulley suction cup 6 is sequentially threaded and fixed with a plane spring 11 and a metal guide disc 14 by screws (not shown in the figure), and the plane spring 11 is simultaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com