LED lamp panel assembly, LED photoelectric module and LED ceiling lamp

A technology of LED ceiling lamps and LED light boards, applied in the field of lighting, can solve problems such as increased reliability risks and complex processes, and achieve the effects of improving cost performance, saving production costs, and simple and direct electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

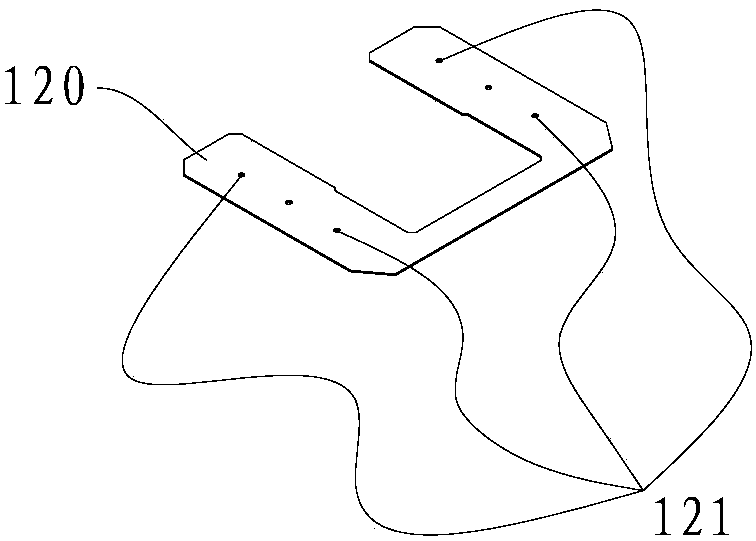

[0050] Such as image 3 and Figure 4 As shown, the LED lamp board assembly of the present invention includes a PCB lamp board 120 and several LED lamp beads 130 arranged on the PCB lamp board 120. The PCB lamp board 120 is a U-shaped lamp board, and the PCB lamp board 120 has two equal-width For the longitudinal side and the horizontal side connecting the two longitudinal sides, the width between the two longitudinal sides of the PCB light board 120 is equal to twice the width of each longitudinal side, such as Figure 5 As shown, H is the width between the two longitudinal sides of the PCB light board 120, that is, the width of the vacant slot in the middle of the two longitudinal sides, A is the width of each longitudinal side of the PCB light board 120, and the width between the two longitudinal sides of the PCB light board 120 is The width is equal to twice the width of each longitudinal side, ie H=2A.

[0051] Such a U-shaped structure can ensure that the PCB lamp pane...

Embodiment 2

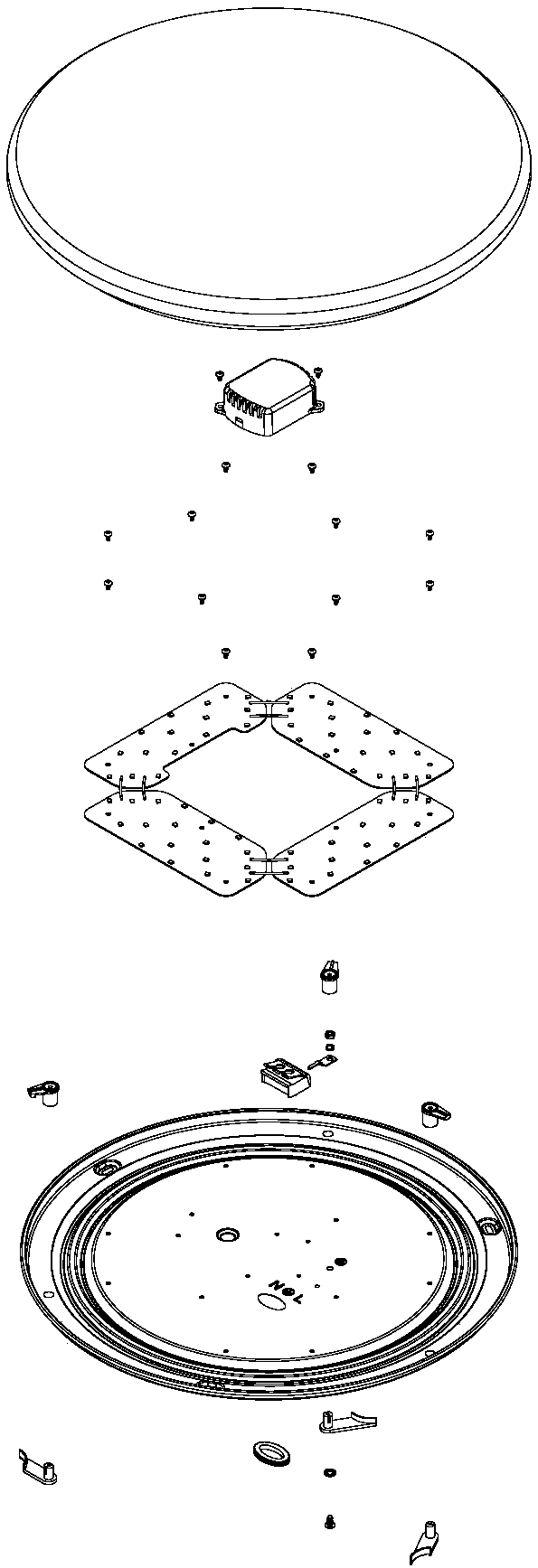

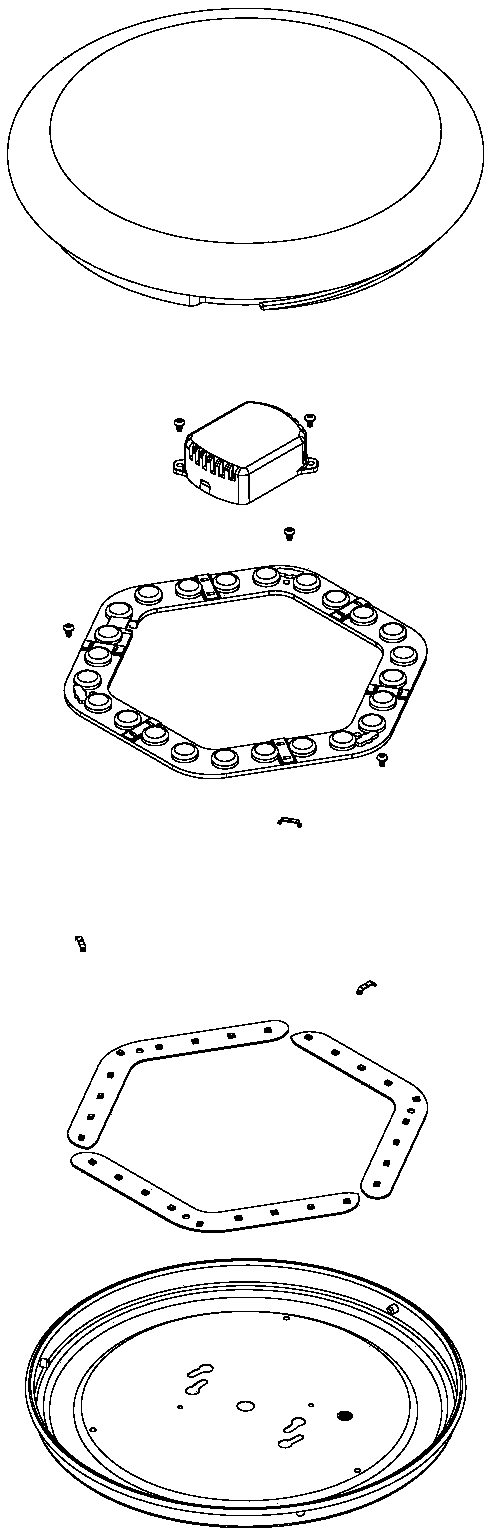

[0064] refer to Figure 14-16 , embodiment 2 is for higher power ceiling lamps, when a larger or longer power driver is required, in order to obtain better light distribution on the outer lampshade, and there is not enough space on the lens to place the power driver, the power driver The scheme fixed on the chassis 210. Such as Figure 10-13 As shown, the volume of the power driver in this embodiment is relatively large, and the longitudinal sides of the LED light board 220 are relatively long. The power driver is fixed on the chassis 210 between the two longitudinal sides of the LED light board. The groove reserves the position of the mounting hole 211 on the chassis 210 .

[0065] The assembly process is as follows: the LED lamp bead 230 and the connection terminal 240 are fixed to the PCB light board 220 by patching to form an LED light board assembly. Then, the assembly of the lens assembly 250 composed of the lens base 251 and the lens 252 and the LED lamp board assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com