Particulate matter sampling rotating shaft inner runner system

A technology of inner flow channel and particulate matter, which is applied in the field of particle detection, can solve the problems that the movement and measuring chamber cannot rotate freely, cannot use the movement reasonably and effectively, and affect the operation of components, etc., to achieve a simple and beautiful exterior of the product and light weight , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

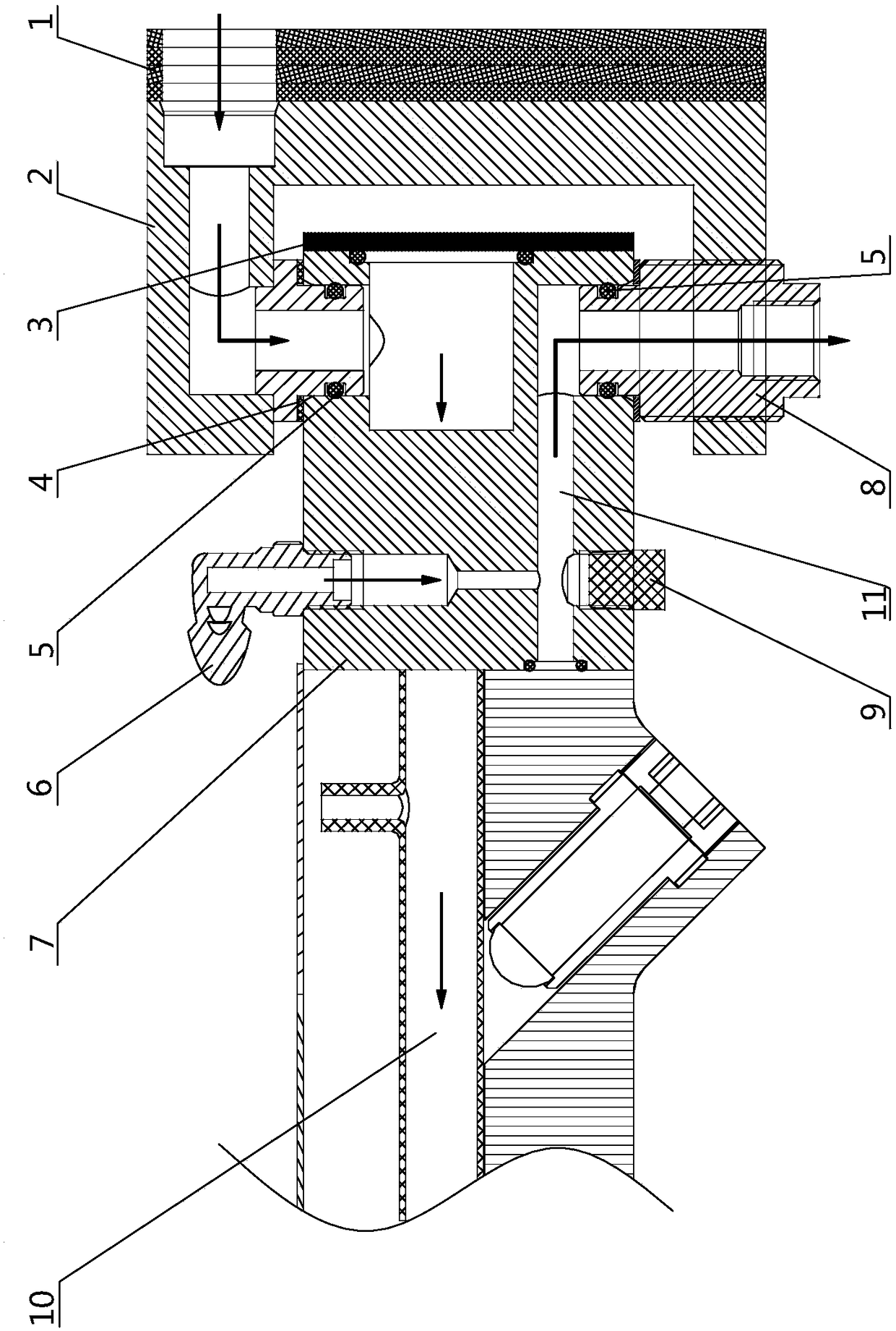

[0035] like figure 1 As shown, the purpose of the technical means implemented in the particle sampling rotating shaft inner channel system described in Embodiment 1 of the present invention is to solve the problem that the rotating shaft of the traditional detection device cannot rotate freely during installation and maintenance, and cannot reach the gas In the state of normal circulation, the problem closely related to installation and maintenance is that if it is implemented according to the structure of the traditional detection device, it needs to be disassembled and the flow path is disconnected during maintenance. Therefore, the technical solution adopted to solve the technical problem includes the shaft seat 2, and the movement 7 that is movably installed on the rotating shaft seat 2 through the corresponding shaft core assembly.

[0036] Analyze the structure between the above-mentioned rotating shaft seat 2 and the rotating shaft assembly:

[0037] The implemented sh...

Embodiment 2

[0048] like figure 1 As shown, the particle sampling shaft inner runner system described in Embodiment 2 of the present invention is a modification based on the technical solution implemented in Embodiment 1, and a supply air supply is formed between the implemented measurement chamber 10 and the external exhaust gas environment. On the basis of the continuous gas circulation channel of the exhaust gas to be measured, a section of gas passage is added between the measurement chamber 10 and the horizontal flow channel 11, so that the measured exhaust gas is discharged along the horizontal flow channel 11 and the vertical flow channel of the lower shaft core 8 to the outside, thus forming two upper and lower circulation flow channel units inside the system, that is, the implemented air intake channel, the vertical flow channel of the upper shaft core, the air intake chamber and the measurement chamber 10 constitute the upper circulation inner flow channel unit that allows the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com