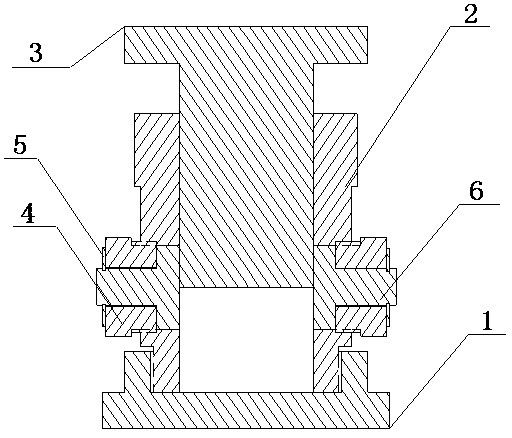

Underground soft coal seam simulating and copying method and small soft seam pressing device

A layered pressing, coal seam technology, applied in the direction of measuring devices, analysis materials, test sample preparation, etc., to achieve the effect of ensuring accuracy, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] For example, in the 3# coal seam of a mine in Yangquan, Shanxi, the measured apparent density of the soft layered coal sample in the original coal seam is 1.36t / m 3 , the raw coal moisture content is 2.7%; the buried depth of the sampling site is 470m, and the average in-situ stress is 11.75MPa. The forming pressure of the coal seam soft layer is measured as 31.78MPa by the method of the above step one. More than 600 kilograms of soft layered coal samples were collected at the site, and sieved with a 6mm sieve in the laboratory to remove coal lumps, and the measured moisture content was only 2.3%. We added about 2.4 liters of water to the coal sample by spraying water, and after stirring evenly, the moisture content of the coal sample was measured to be 2.72%. Store in an airtight bucket for later use. Then press the coal sample with a molding pressure of 31.78MPa according to the method of the above-mentioned step 2, and then maintain a stress of 11.75MPa. Each time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com