Wind turbine blade gas bubble detection apparatus

A technology for wind turbines and detection devices, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

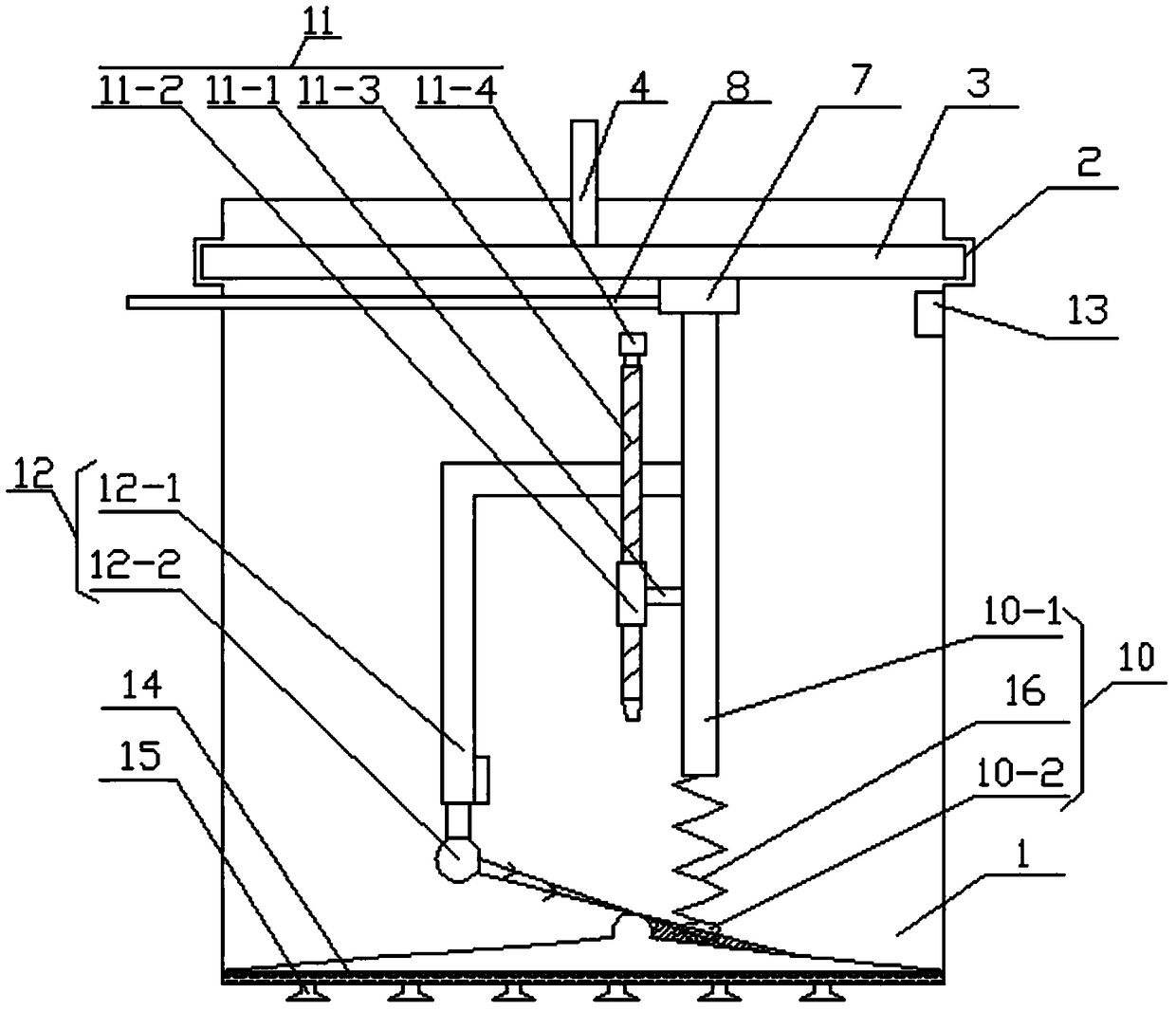

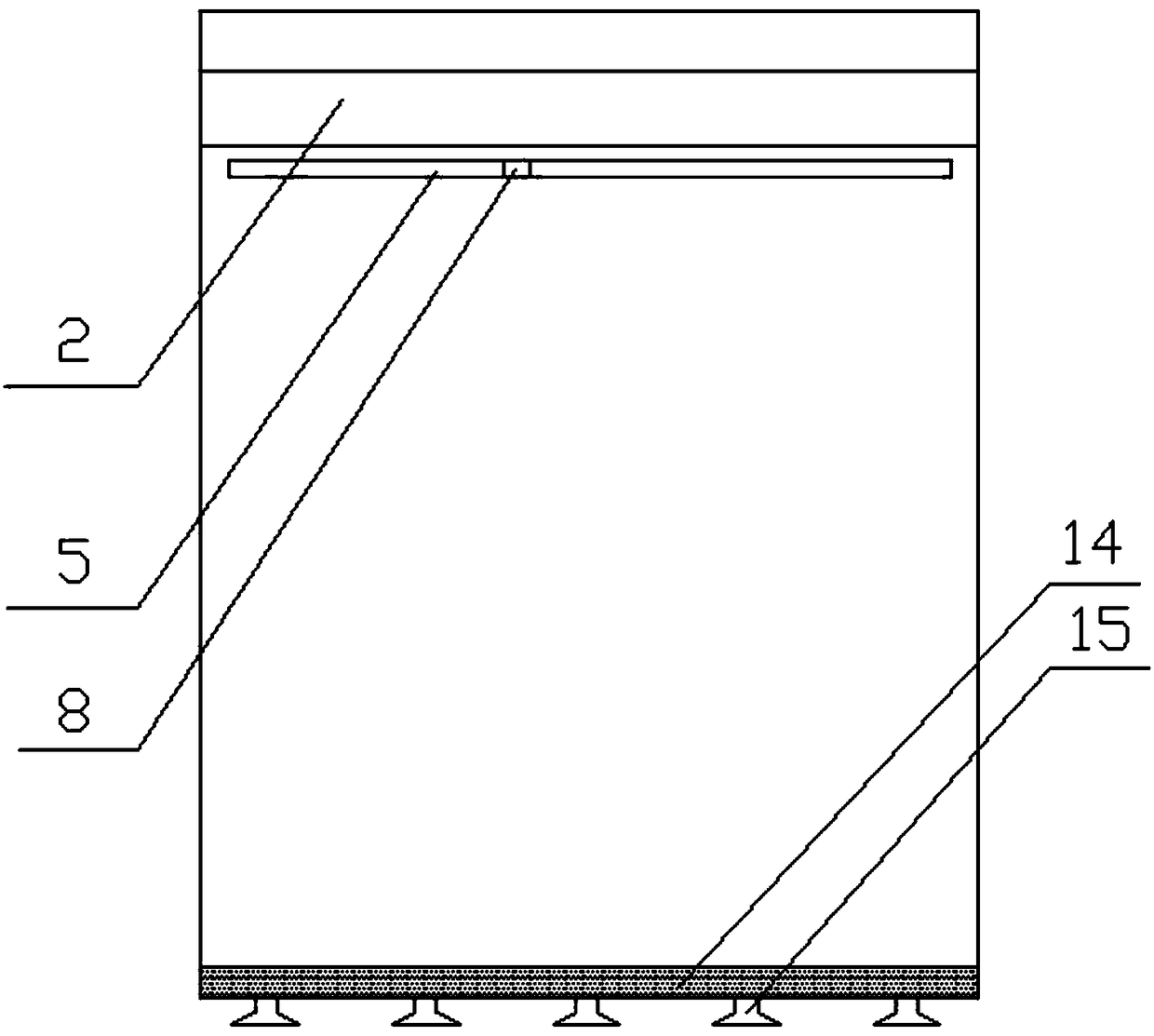

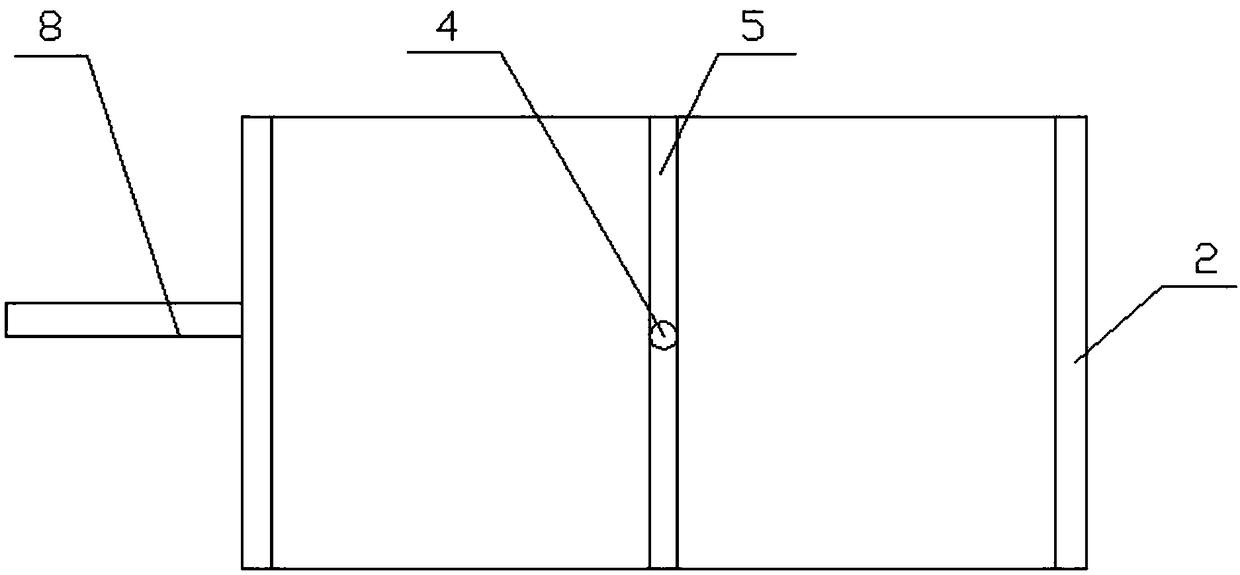

[0016] The present invention is a wind turbine blade air bubble detection device, which is characterized in that it includes a black box 1, a chute 2, a beam 3, a strip hole 5, a moving rod 4, a push rod 8, a slider 7, a sliding track 6, and an induction mechanism 10. Marking mechanism 11, lighting device 12, shading structure 9, controller 13, sponge layer 14, suction cup 15, chute 2 is installed on the left and right sides of camera obscura 1, and the two ends of beam 3 are respectively installed in two chute 2 , the crossbeam 3 is located between the two chutes 2, the crossbeam 3 is fixed with a moving rod 4, the camera obscura 1 is provided with a strip hole 5, the crossbeam 3 is provided with a slide track 6, and the slide track 6 is provided with a slider 7, The push rod 8 is fixed on the side of the slide block 7, the left side of the camera obscura 1 is provided with a strip hole 5, and the strip hole 5 is located below the chute 2, and the strip hole 5 above the camera...

Embodiment 2

[0018] When in use, put the present invention on the fan blade as a whole, press the dark box 1, so that the suction cup 15 is sucked on the fan blade, and at the same time, the sponge layer 14 is attached to the fan blade due to pressure deformation, and the dark box can be closed to prevent light from entering the dark box , then the battery powers the lighting lamp 12-2, manually pushes the push rod 8, the slider 7 slides in the sliding track 6, and the slider 7 drives the vertical bar 10-1 and the spring 16 to make the photosensitive sensor 10-2 on the surface of the fan blade At the same time, the vertical bar 10-1 drives the lighting device 12 and the marking mechanism 11 to move. When the light hits the air bubbles, since the air bubbles will cover the light, a shadow will be formed on one side of the air bubbles. When the photosensitive sensor 10-2 moves to the position of the shadow , the photosensitive sensor 10-2 sends a signal to the controller 13, and the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com