Sewage plant electric control system

A technology for electrical control systems and sewage plants, applied in the mechanical field, can solve problems such as current exceeding the rated value, load increase, voltage increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

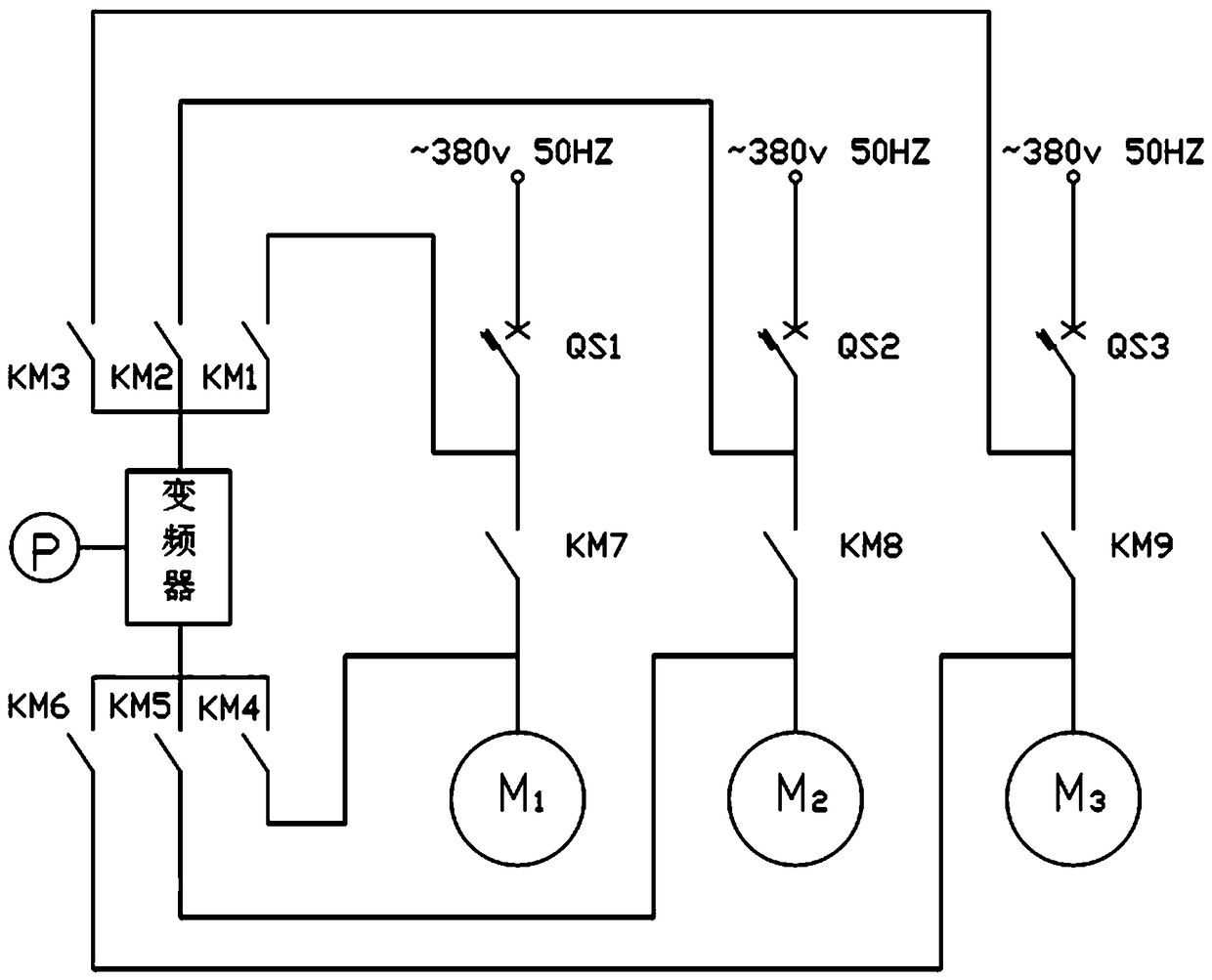

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] like figure 1 , in the initial design of the system, if the corresponding electrical automatic protection device is installed in the system, only related faults occur in the electrical control system, the automatic protection device can quickly find out the fault location and fix it Separate from non-faulty parts, so that the whole system can return to normal in a short period of time, or stop running completely in an instant, so as to effectively avoid the occurrence of larger fault accidents. At the same time, the electrical automatic protection device can also play a monitoring role, which can reflect the real situation of electrical equipment operation. In the daily operation of electrical equipment, the protection device can play a corresponding role according to the difference in normal operating conditions of different electrical equipment and the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com