Product inspection system

A patrol inspection system and product technology, applied in the direction of data processing applications, resources, calculations, etc., can solve the problems of inability to collect inspection records and alarms, low work efficiency, data integration and data analysis difficulties, etc., to achieve optimization The effect of integration, simple structure and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

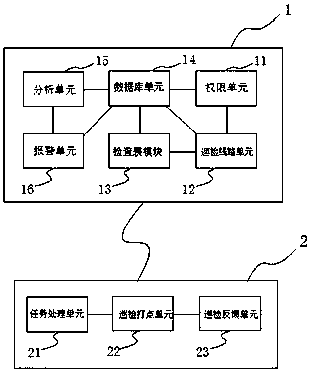

[0023] A product inspection system includes a server 1 and an on-site inspection device 2 .

[0024] Wherein, the server 1 adopts a personal computer terminal or an enterprise computer terminal, which includes an authority unit 11 , an inspection line unit 12 , a checklist unit 13 , a database unit 14 , an analysis unit 15 and an alarm unit 16 . The on-site inspection device 2 adopts a smart phone, a handheld PDA, a tablet computer or other handheld embedded devices, and includes a task processing unit 21 , an inspection management unit 22 , and an inspection feedback unit 23 .

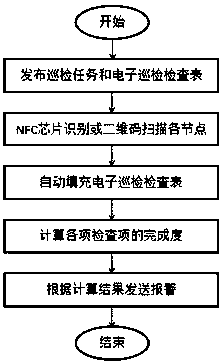

[0025] The authority unit 11 is used to assign different viewing authority and task release authority to different users; the inspection line unit 12 is used to issue the inspection route to the on-site inspection device 2, and preset the standard attribute data of each node of the inspection line; check The table unit 13 is used for automatically generating an electronic inspection checklist for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com