Material washing device

A material and scrubber technology, applied in the field of material scrubbing devices, can solve the problems of uncontinuous operation, environmental pollution, long time consumption, etc., and achieve the effects of small occupied space, simple manufacture, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

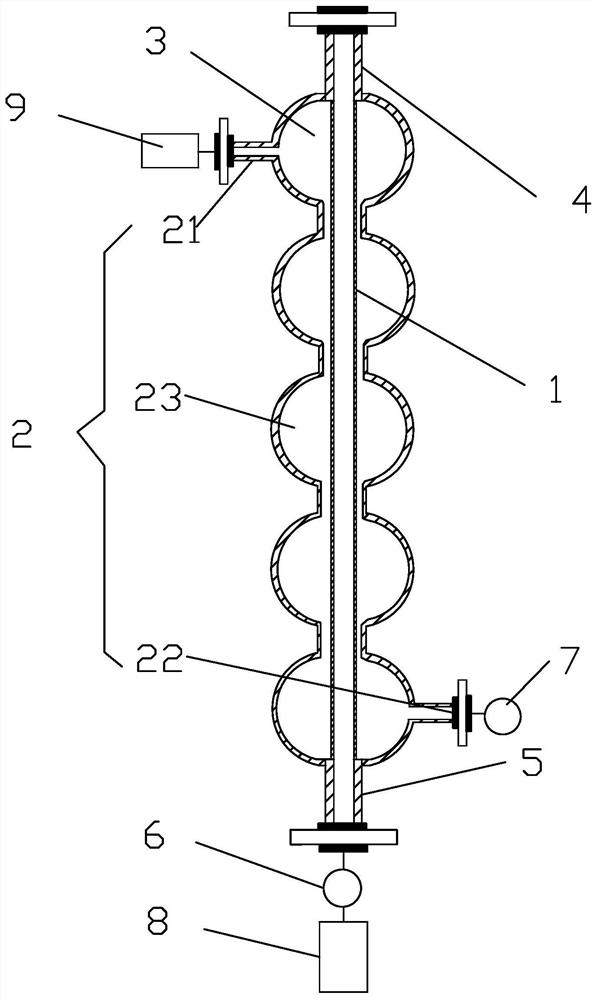

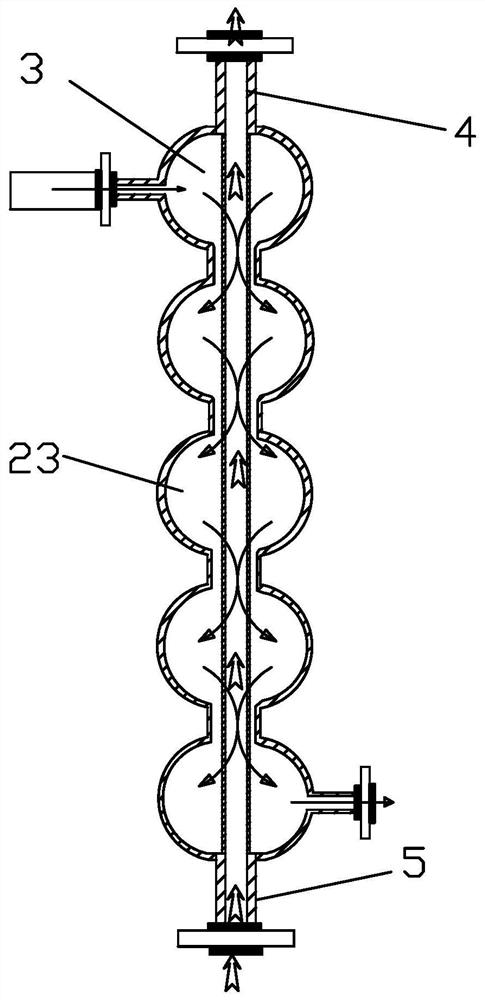

[0022] A material scrubber, characterized in that it includes a vertical cylindrical filtering inner tube 1, a washing outer tube 2 fixedly socketed outside the filtering inner tube 1, and a washing space between the filtering inner tube 1 and the washing outer tube 2 Cavity 3;

[0023] The pipe wall of the washing outer pipe is made of solid material, the pipe wall of the filter inner pipe is made of filter screen, and the upper and lower ends of the filter inner pipe are respectively connected with a discharge pipe 4 and an inlet pipe made of solid material. Barrel 5;

[0024] The feed pipe 5 is connected with the material supply device 8;

[0025] The sidewalls at the upper and lower ends of the outer washing pipe 2 are respectively provided with a liquid inlet 21 and a liquid outlet 22 that connect the washing cavity 3 with the outside, and the outer washing pipe is composed of a plurality of pipes arranged in sequence along the extending direction of the pipe body. And ...

Embodiment 1

[0034] Such as figure 1 As shown, a material scrubber is characterized in that: it includes a vertical cylindrical filtering inner tube 1, a washing outer tube 2 fixedly sleeved outside the filtering inner tube 1, and a filter inner tube 1 and a washing outer tube 2. Has a washing cavity 3;

[0035] The pipe wall of the washing outer pipe is made of solid material, the pipe wall of the filter inner pipe is made of filter screen, and the upper and lower ends of the filter inner pipe are respectively connected with a discharge pipe 4 and an inlet pipe made of solid material. Barrel 5;

[0036] The feed pipe 5 is connected with the material supply device 8;

[0037] The sidewalls at the upper and lower ends of the outer washing pipe 2 are respectively provided with a liquid inlet 21 and a liquid outlet 22 that connect the washing cavity 3 with the outside, and the outer washing pipe is composed of a plurality of pipes arranged in sequence along the extending direction of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com