Steel lifting device

A technology of supporting steel and driving device, which is used in the attachment of sawing machines, large fixed members, metal sawing equipment, etc., to achieve the effect of strong applicability, wide product coverage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

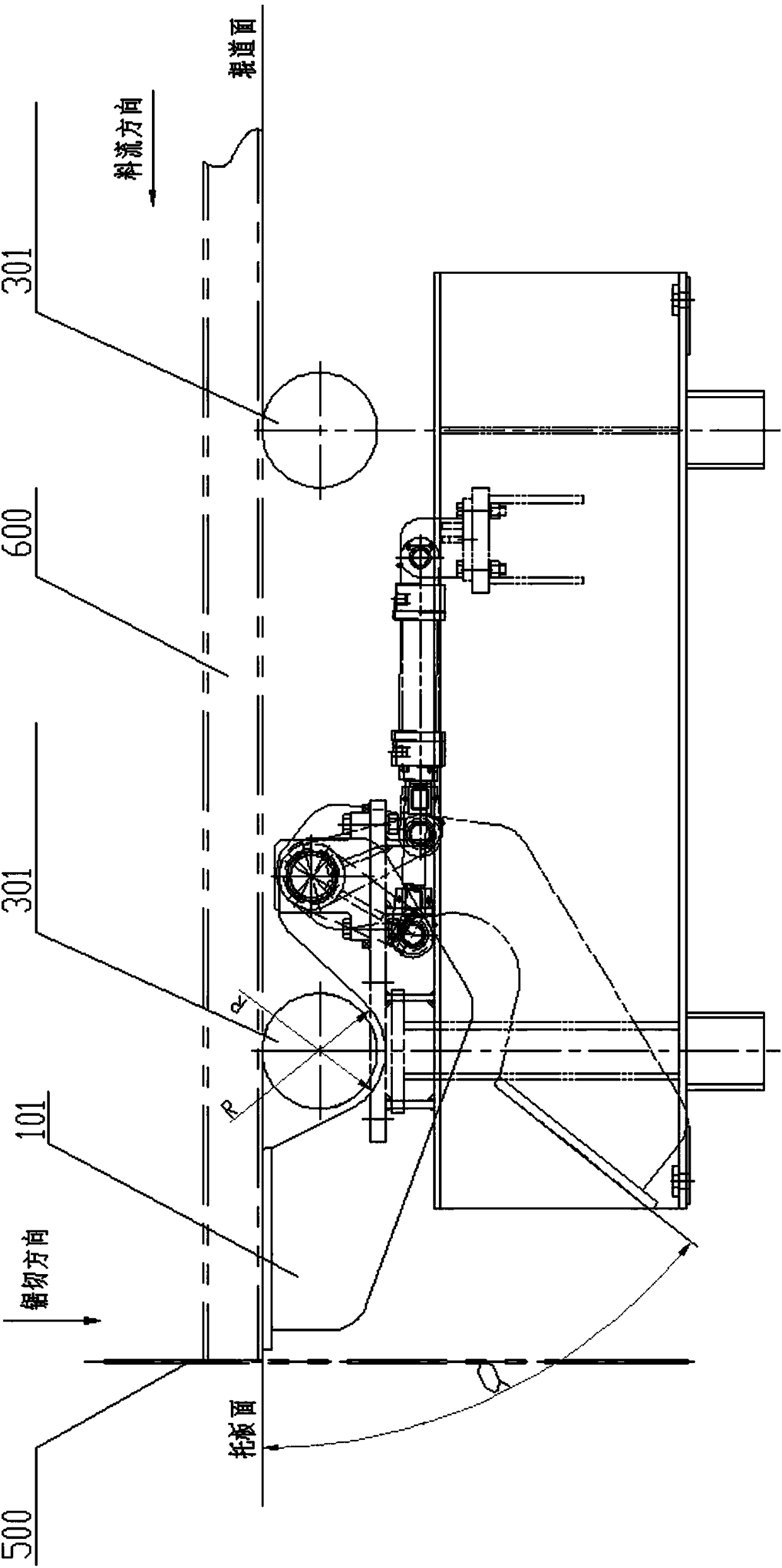

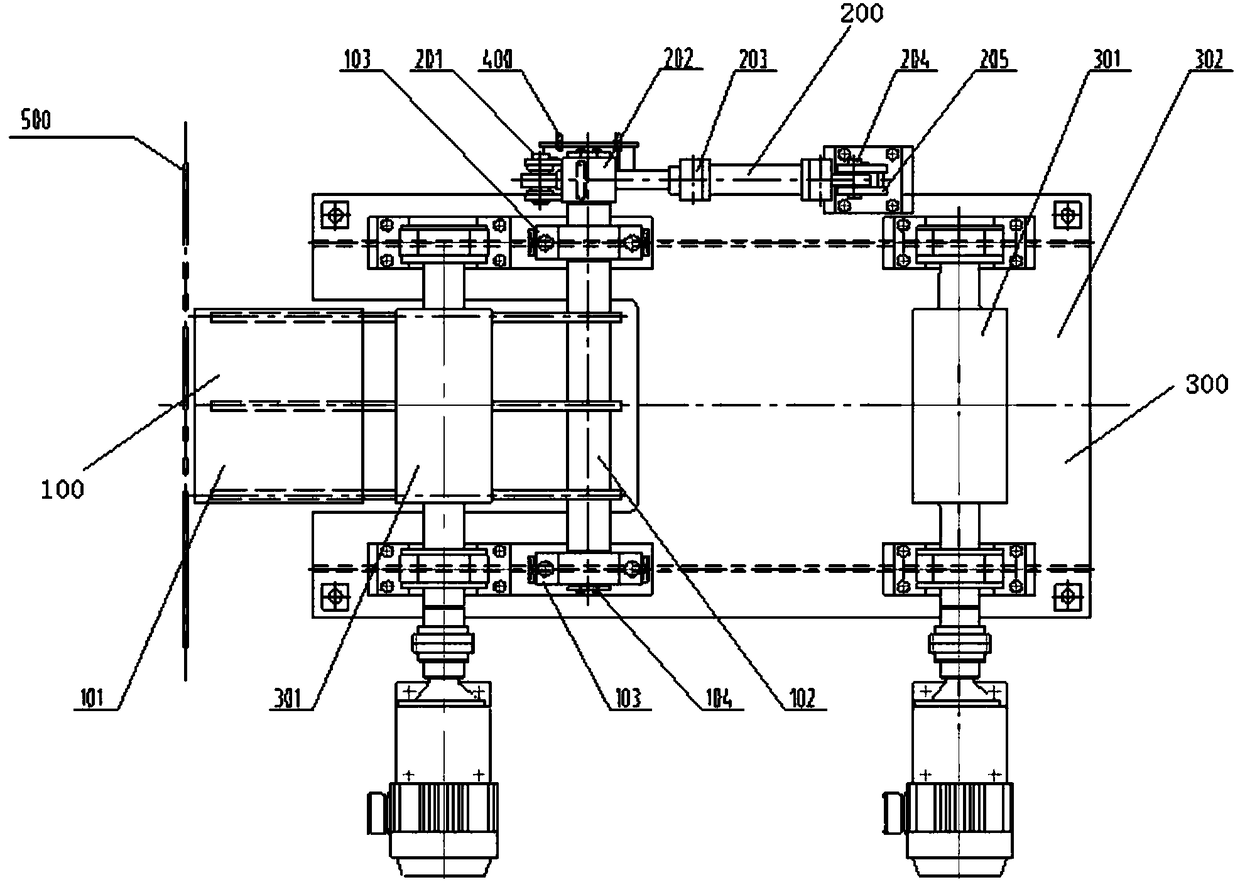

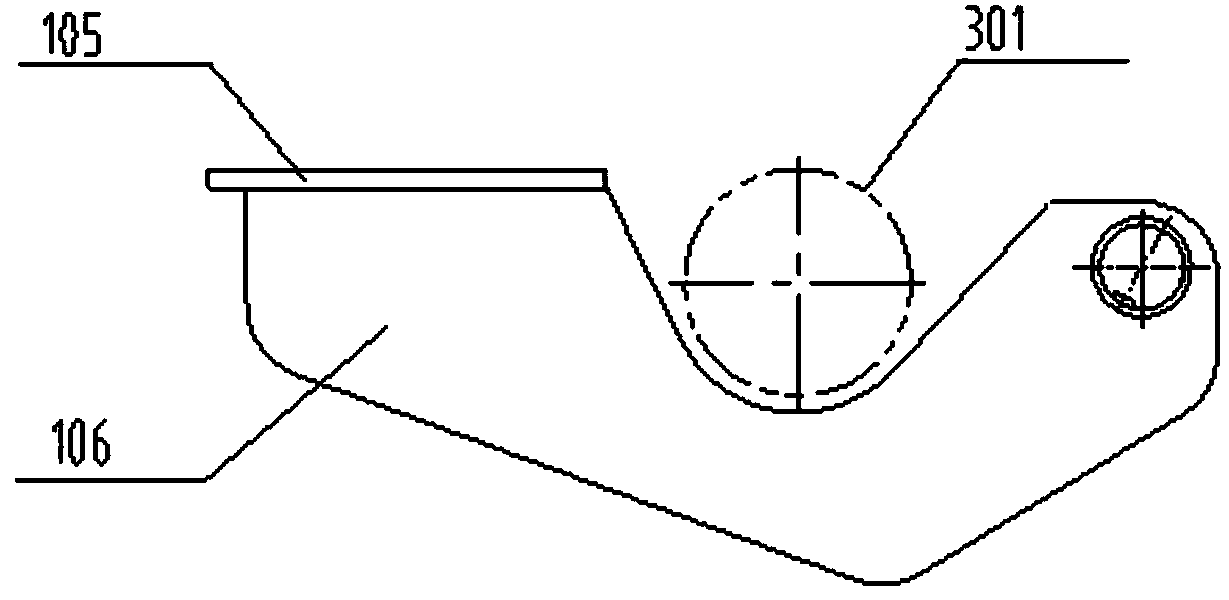

[0021] Such as figure 1 , figure 2 As shown, the whole set of steel supporting device is composed of four major parts: a supporting plate device 100 , a driving device 200 , a steel supporting roller table 300 , and a detection device 400 . The pallet device 100 is made up of a pallet 101 , a pallet support shaft 102 , and a bearing seat 103 , and the pallet device is fixed on the roller frame 302 by connecting bolts. The roller table frame 302 and two roller assemblies 301 form the supporting steel roller table 300, and the roller assembly 301 is fixed on the roller table frame 301 by bolts. The driving device 200 is connected with the pallet device 100 and is arranged on the roller frame 302 ; the detection device 400 is arranged at the connection between the pallet device 100 and the driving device 200 , and transmits signals to control the driving device 200 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com