Crankshaft numerical control welding machine head device

A welding head and welding torch technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effect of improving work efficiency, ensuring quality, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

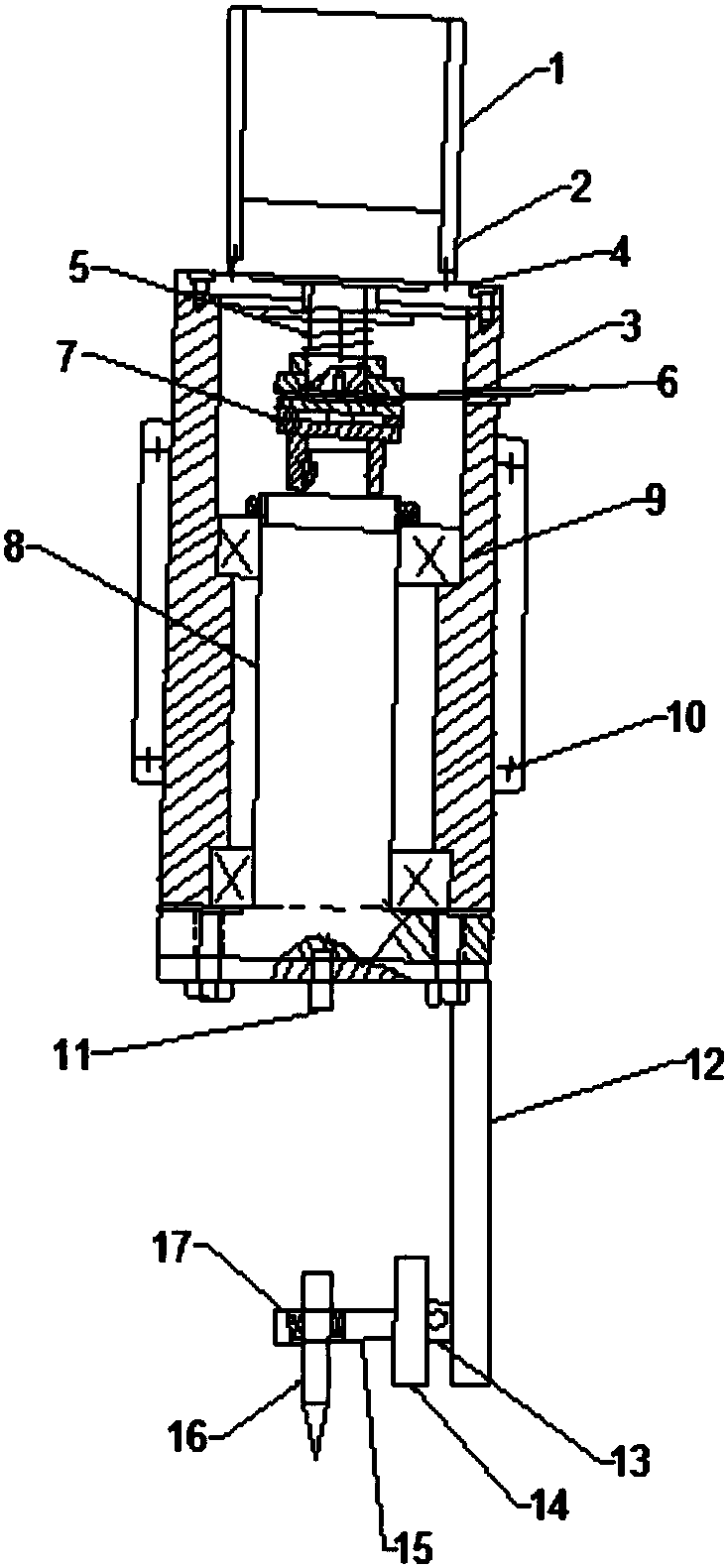

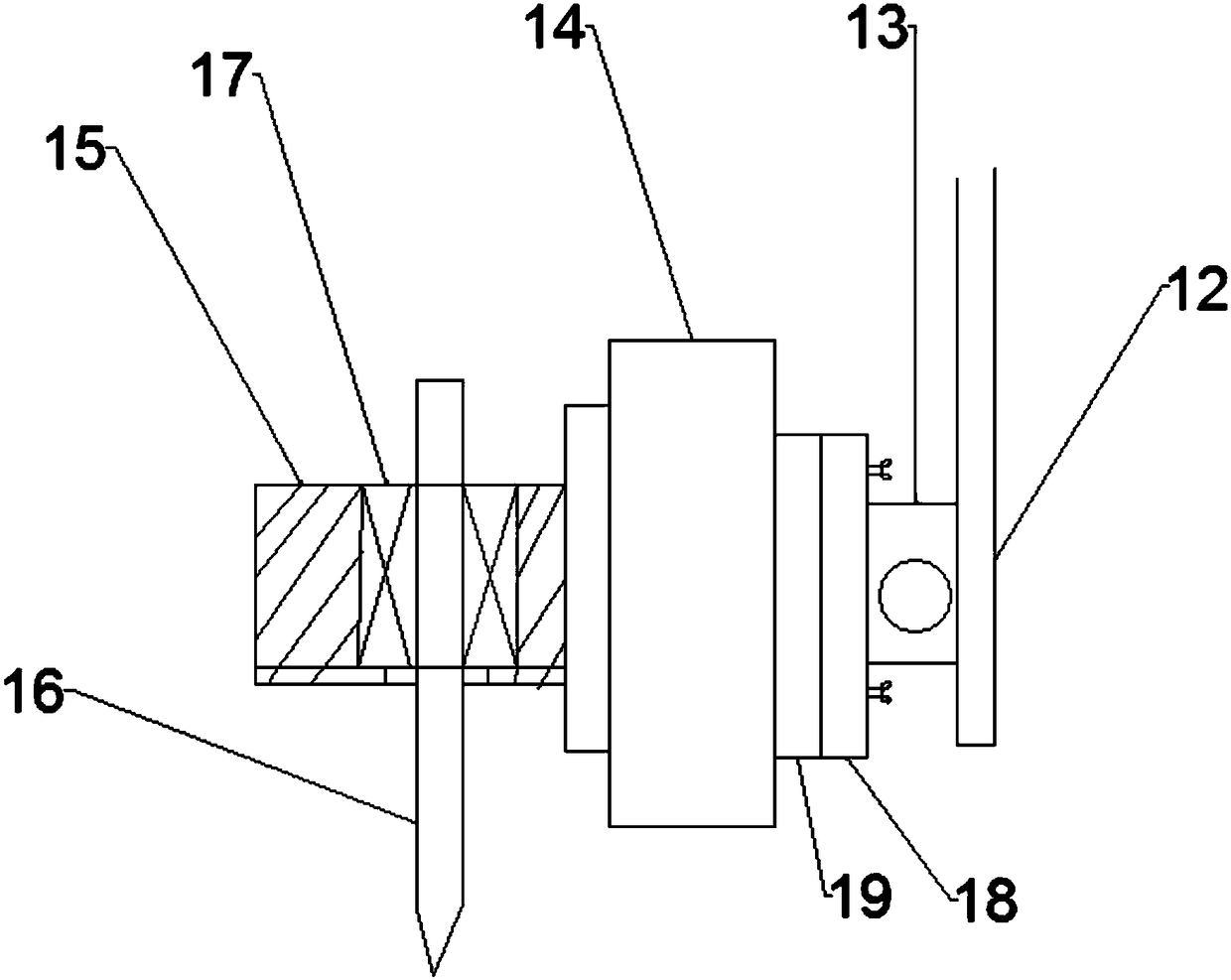

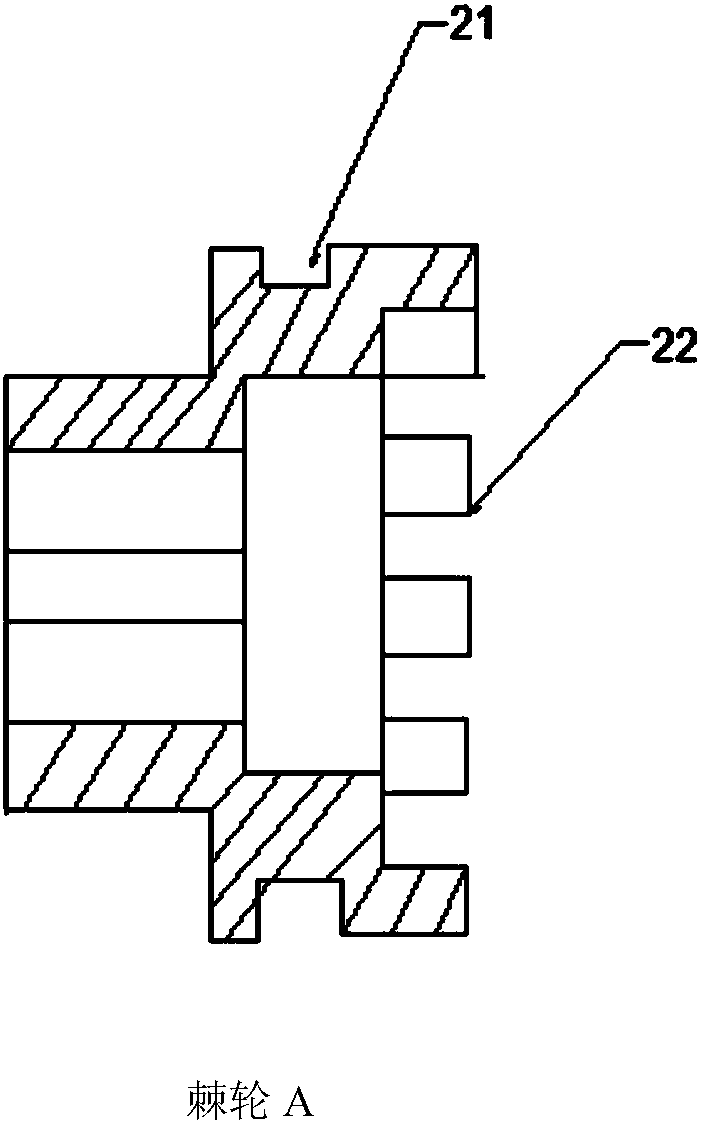

[0018] A crankshaft-type numerical control welding head device, including a casing 3, a servo motor 1, a reducer 2, a ratchet group 7, a transmission shaft 8, a mounting plate 12, an oscillator 14, and a welding torch 16. The reducer 2 passes through the ratchet group 7 is connected with the transmission shaft 8, the transmission shaft 8 is fixed inside the casing 3 through two roller bearings 9, the transmission shaft 8 is connected to the mounting plate 12, and the welding torch bracket 15 is arranged on the mounting plate 12, and the welding torch 16 is fixed on the welding torch support 15 through the welding torch bearing 17, and one side of the welding torch support 15 is provided with a swinger 14.

[0019] The housing 3 is provided with a gland 4, the reducer 2 is installed on the gland 4, and the upper part of the reducer 2 is provided with a servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com