Vacuum defoaming device and method for epoxy resin cured at room temperature

An epoxy resin, room temperature curing technology, applied in the direction of foam dispersion/prevention, can solve the problem of no cooling measures, etc., achieve the effect of improving pouring quality, prolonging curing time, and meeting the needs of vacuum degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

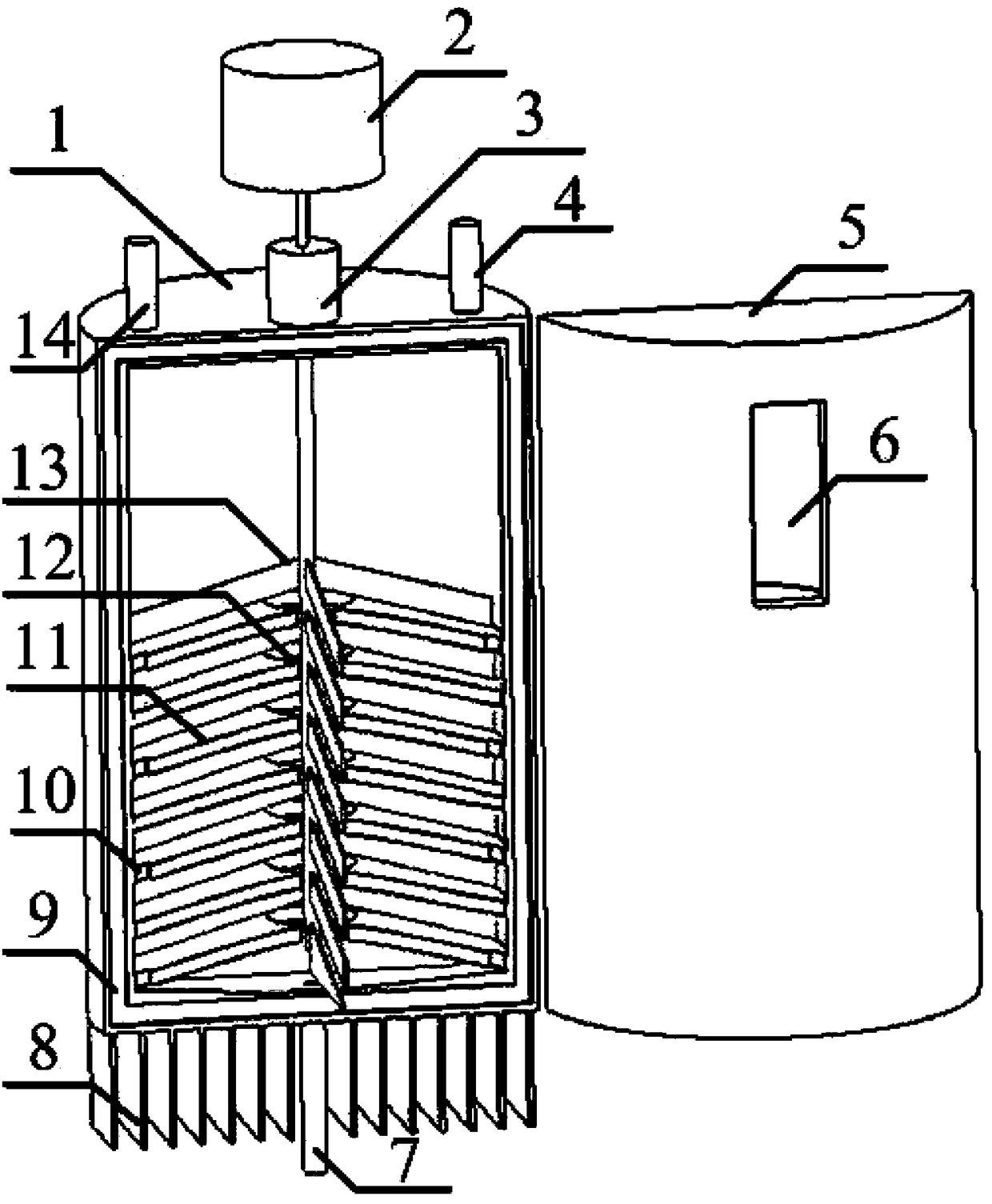

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] like figure 1 As shown, a room temperature curing epoxy resin vacuum pouring device includes a degassing tank, the degassing tank main body 1 and the degassing tank hatch 5 are sealed by an O-shaped sealing ring 9, and the degassing tank hatch 5 is provided with Quartz glass observation window 6, the top of the degassing tank main body 1 is provided with a feed port 14 and an air extraction port 4, and the bottom of the degassing tank main body 1 is provided with a current collector and a discharge port 7; it also includes a cooling device, which is composed of internal cooling fins 11. The wall of the defoaming tank and the outer cooling fins 8 are composed. The inner cooling fins 11 are composed of seven umbrella-shaped heat-conducting fins distributed along the axial direction of the main axis of the defoaming tank. The spacing of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap