Method for manufacturing shoe outsole with TPU high-low-temperature film

A high-low temperature film and shoe outsole technology, applied in footwear, other household appliances, household appliances, etc., can solve the problems of restricting the application of TPU and high production costs, increase adhesion, fast production speed, and meet the requirements of intelligent production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Detailed specific embodiments of the present invention will be disclosed herein. It is to be understood, however, that the disclosed embodiments are merely typical examples of the invention, which may be embodied in many alternative forms. Therefore, specific structural and functional details disclosed herein are not limiting, but merely serve as a representative basis for describing various implementations to one skilled in the art in accordance with the claims.

[0039] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

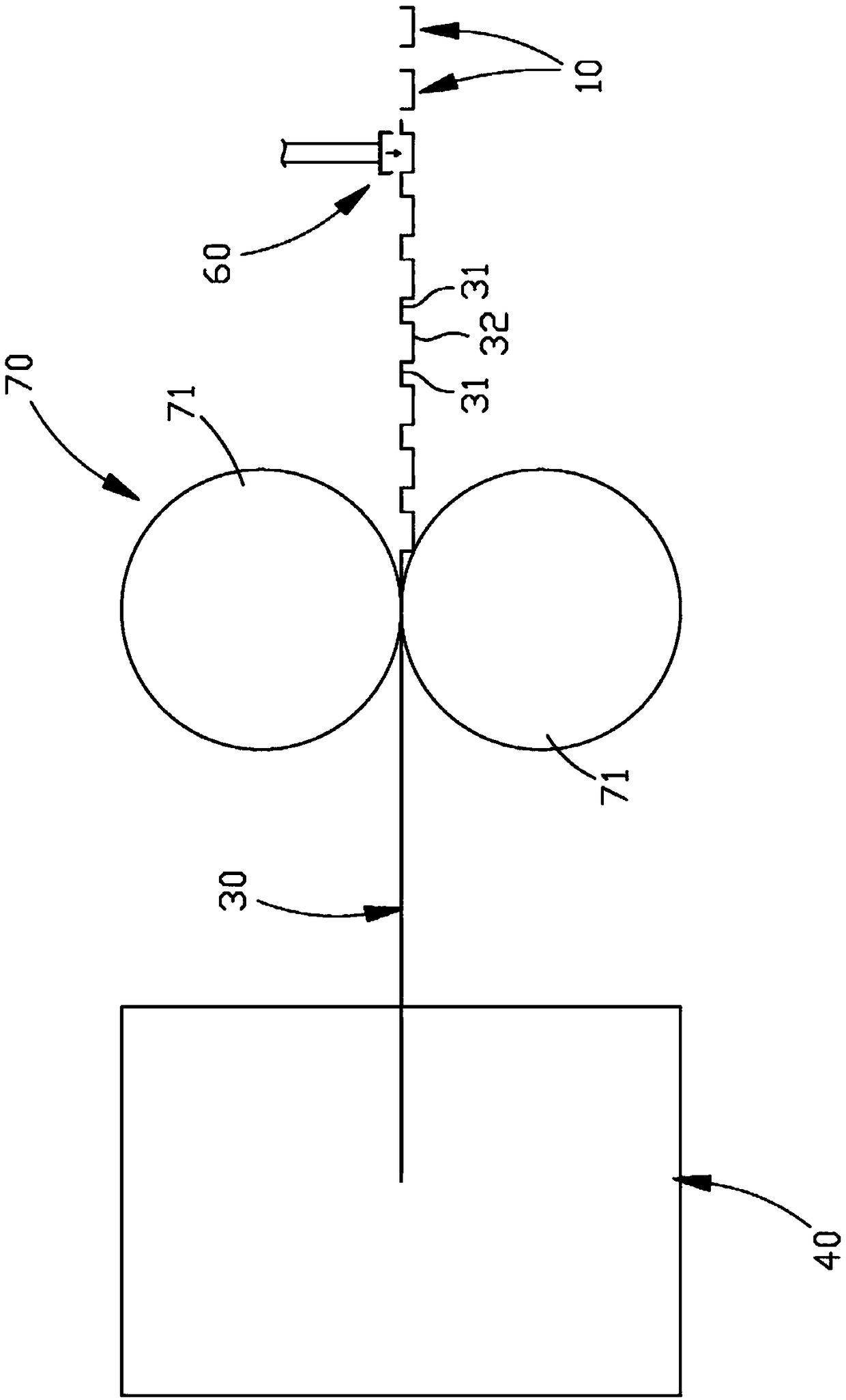

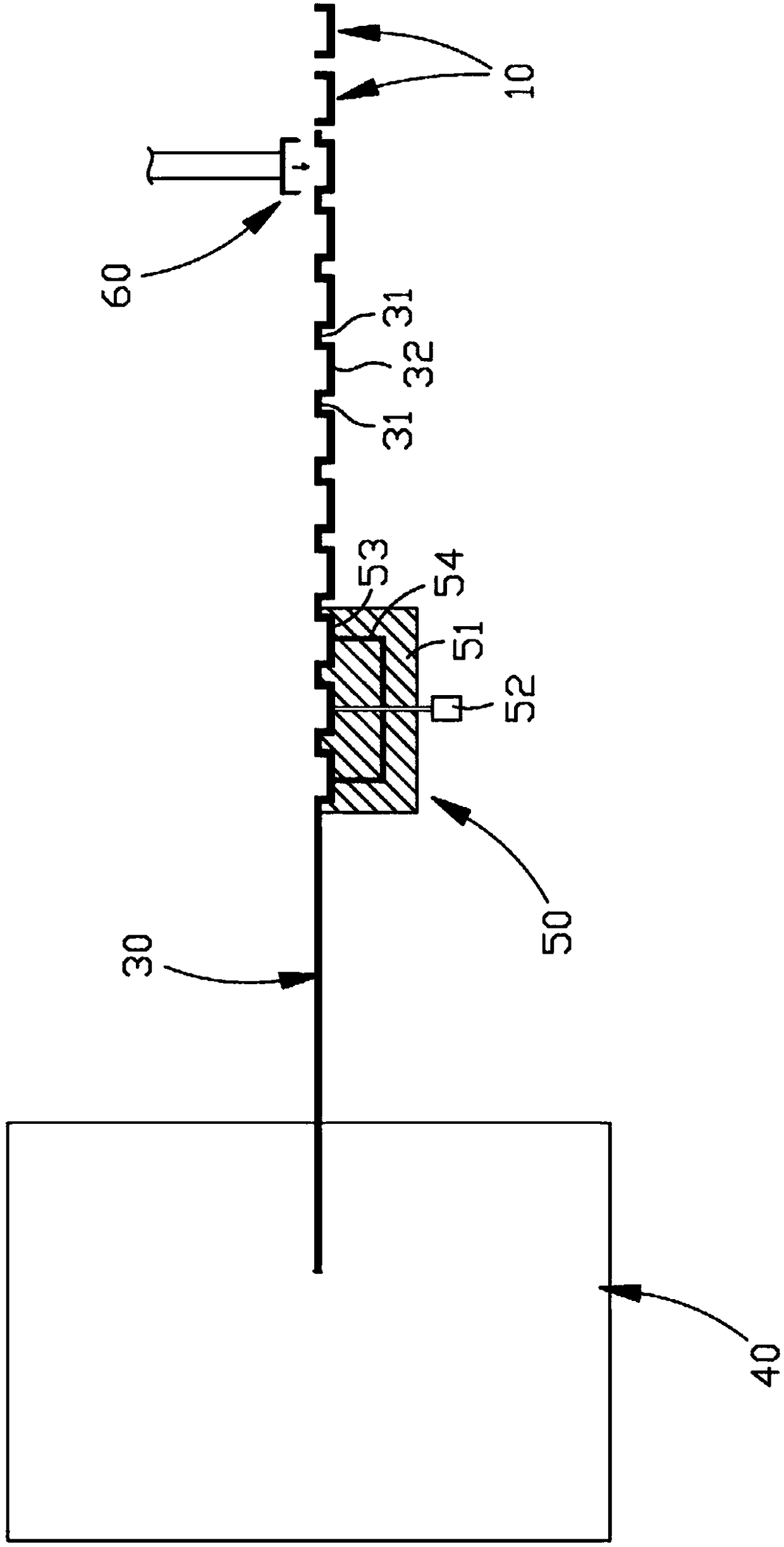

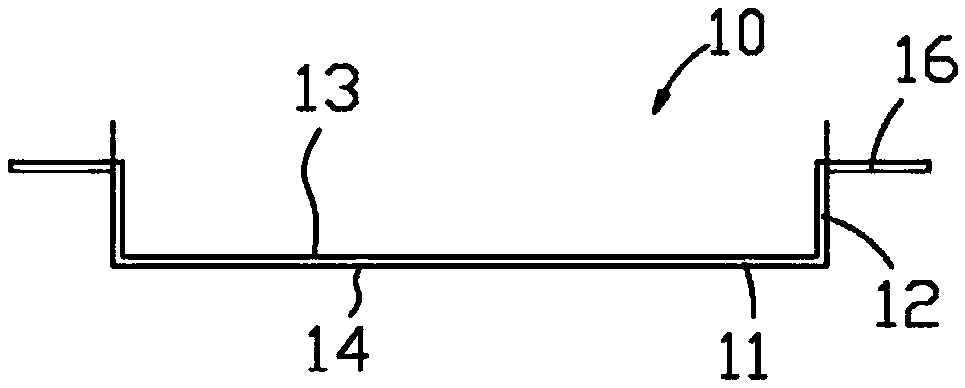

[0040] The invention provides a method for preparing a shoe outsole from a TPU high-low temperature film, which comprises a TPU casting film forming step, a three-dimensional forming step, a die-cutting forming step, a shoe sole material entering a mold step, and an in-mold heating forming step. in:

[0041] The TPU cast film forming step:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com