a kind of sf 6 and n 2 Device and method for rapid recovery and treatment of mixed gas

A technology of mixed gas, recovery and treatment, applied in chemical instruments and methods, sulfur and halogen compounds, nitrogen compounds, etc., can solve the problems of increasing costs, wasting energy, and high gas prices, reducing emissions and improving recovery and processing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

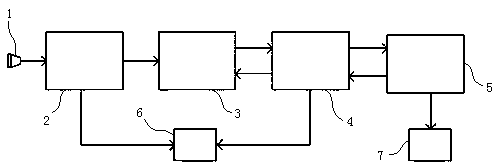

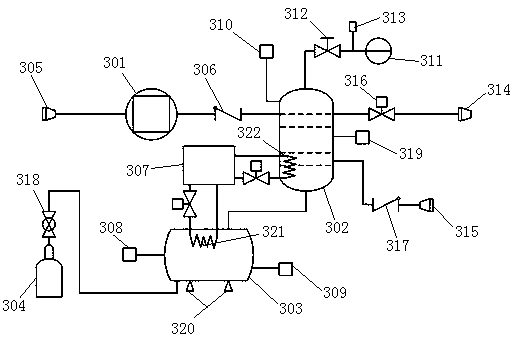

[0034] as attached Figure 1-5 As shown, the present invention SF 6 and N 2 Mixed gas rapid recovery processing device, including check valve 1, dry filter device 2, SF 6 Recovery device 3, gas separation device 4 and nitrogen recovery device 5; SF is installed on the dry filter device 2 and gas separation device 4 through pipelines 6 Gas analyzer 6, install SF through pipeline on nitrogen recovery device 5 6 Gas detector 7. The SF 6 The model of gas analyzer 6 is RA912FⅡ, which can realize SF 6 Gas purity, micro water and decomposition detection; SF 6 The model of gas detector 7 is PGD1-A-SF 6 , the SF 6 Gas detector can realize SF 6 Gas trace concentration detection.

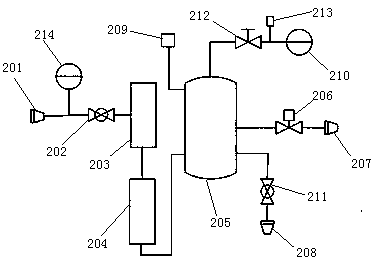

[0035] The present invention SF 6 and N 2 Mixed gas rapid recovery processing device, the dry filter device 2 includes a first self-sealing joint 201, a first ball valve 202, a drying tank 203, a filter tank 204 and a first buffer tank 205 connected in sequence through pipelines; the first self-sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com