A kind of preparation method of nitrogen-doped graphene material based on diaminoazofurazan

A technology of diaminoazofuran and nitrogen-doped graphene, which is applied in the fields of graphene, chemical instruments and methods, nano-carbon, etc., and can solve problems such as limited application and difficult compounding of graphene materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

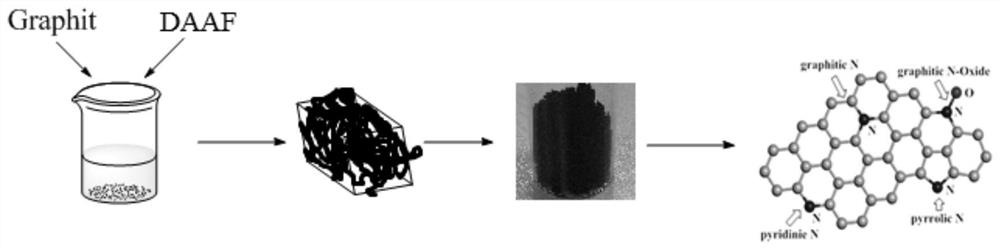

[0017] Please refer to figure 1 , figure 1 A schematic flow diagram of a method for preparing a nitrogen-doped graphene material based on diaminoazofurazan is provided for an embodiment of the present invention, wherein the method includes:

[0018] Step 1. Disperse graphene in water, add diaminoazofurazan (DAAF) solution, heat at 50-70°C for 30-60min, cool down to 20-40°C, and dry to obtain graphene-coated DAAF co- Crystal;

[0019] Wherein, the mass ratio of graphene and DAAF is 1:1~10;

[0020] Step 2: Grinding the DAAF eutectic into powder and heating at 500-800°C for 3-5 hours to obtain a nitrogen-doped graphene material.

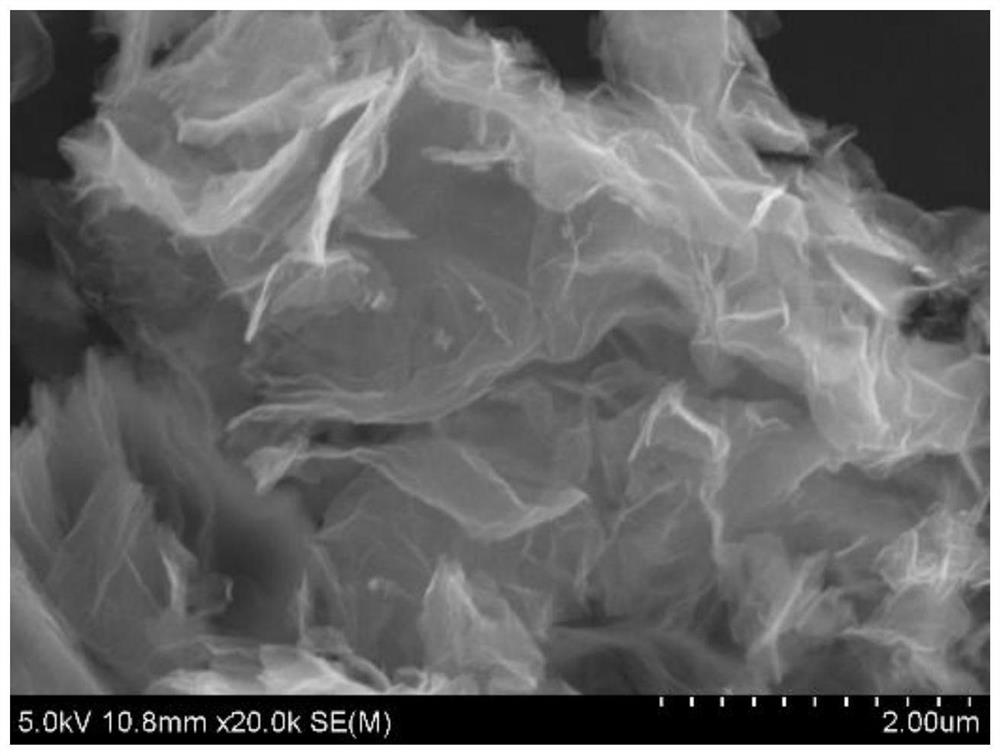

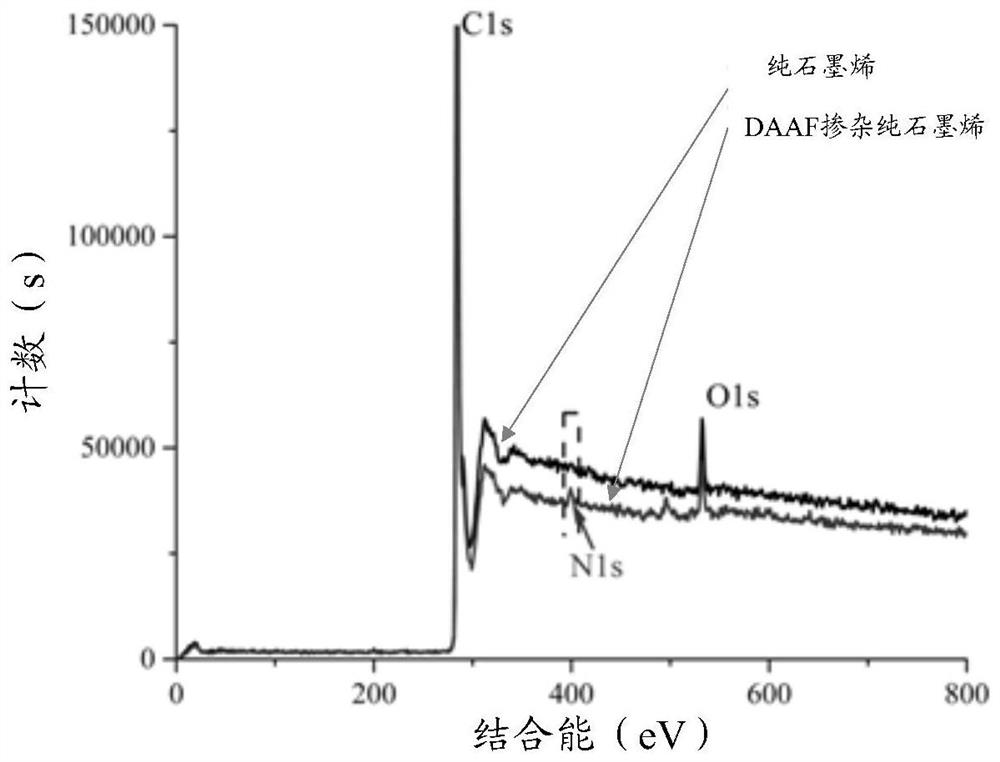

[0021] The preparation method of nitrogen-doped graphene material provided by the present invention uses DAAF to react with graphene to obtain graphene material with higher nitrogen-doped content. In this material, graphene is evenly coated on the surface of the DAAF crystal, without the use of additives such as adhesives, and the surface propertie...

Embodiment 1

[0029] Add 0.1 g of graphene with a sheet diameter of 0.2 μm to 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser and ultrasonically for 60 minutes to obtain 4 mg / ml graphite Alkene solution.

[0030] Dissolve 0.8 g DAAF into 25 ml ethanol, add the above graphene solution, heat at 50 °C for 30 min, cool down to 20 °C, and dry for 48 h to obtain a graphene-coated DAAF eutectic.

[0031] The DAAF eutectic was ground into powder, heated to 500°C in a tube furnace, and kept for 3 hours to obtain a nitrogen-doped graphene material with a nitrogen content of 5.16%.

Embodiment 2

[0033] Add 0.1 g of graphene with a sheet diameter of 100 μm into 25 ml of deionized water, stir magnetically at 600 r / min for 60 minutes, then place it in an ultrasonic disperser, and ultrasonicate for 30 minutes to obtain 4 mg / ml graphene solution.

[0034] Dissolve 0.4g DAAF into 25ml ethanol, add the above graphene solution, heat at 70°C for 60 min, cool down to 40°C, and dry for 48h to obtain graphene-coated DAAF eutectic.

[0035] Grind the DAAF eutectic into powder, heat it in a tube furnace to 800°C, and keep it for 5 hours to obtain a nitrogen-doped graphene material with a nitrogen content of 4.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com