Nitrogen-doped carbon nanosheet, preparation method and application thereof

A technology of nitrogen-doped carbon and nanosheets, applied in nano-carbon, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low nitrogen doping amount and high cost, and achieve high nitrogen doping content , reduce the preparation cost, and have excellent structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

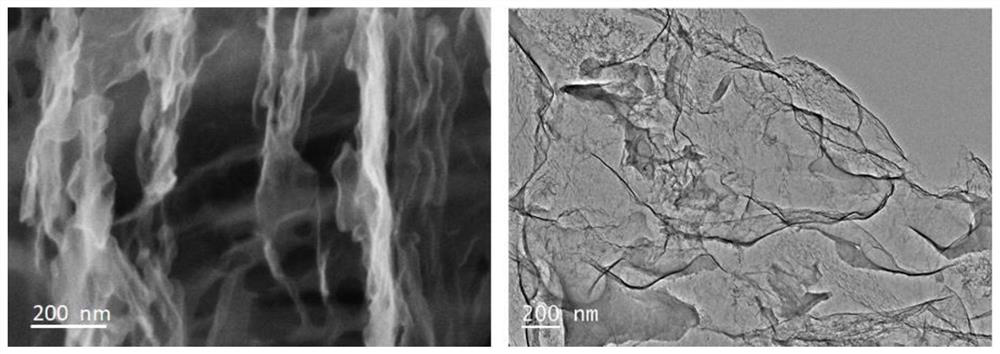

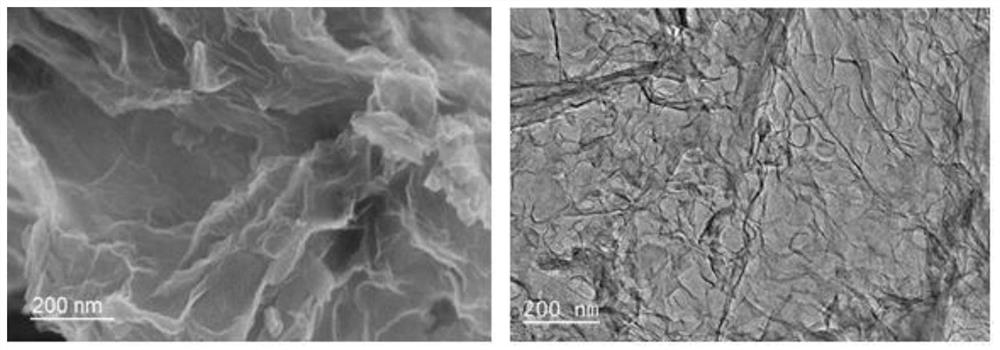

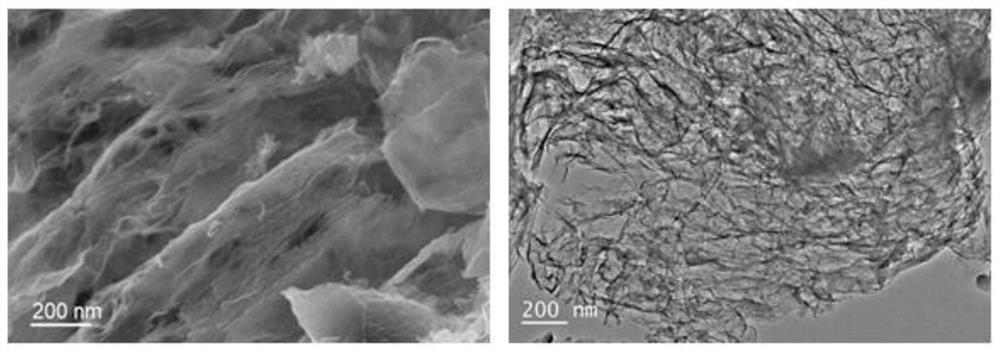

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing nitrogen-doped carbon nanosheets, comprising the following steps:

[0037] Mix and disperse petroleum-based materials rich in aromatic components and nitrogen-containing small molecules in toluene solution, distill the toluene completely at 60-90°C, and grind to obtain a uniformly mixed precursor;

[0038] The homogeneously mixed precursor was subjected to a high-temperature carbonization under a nitrogen atmosphere to obtain a two-dimensional g-C 3 N 4 Carbon materials for template intercalation;

[0039] For the above two-dimensional g-C 3 N 4 The carbon material intercalated by the template is fully ground, and a second high-temperature heat treatment is performed in a nitrogen atmosphere to remove the template to obtain nitrogen-doped carbon nanosheets.

[0040] The preparation method uses petroleum-based materials rich in aromatic components as raw materials to reduce the preparation cost, and the synthesized carbon...

Embodiment 1

[0052] FCC oil slurry rich in aromatic components and melamine were mixed and dispersed in the toluene solution at a ratio of 1:4, the toluene was completely distilled off at 90°C, and a uniformly mixed precursor was obtained after grinding;

[0053] The homogeneously mixed precursor was subjected to a high-temperature carbonization under a nitrogen atmosphere at a heating rate of 1.0°C / min, a carbonization temperature of 550°C, and a carbonization time of 3 hours to obtain a two-dimensional g-C 3 N 4 Carbon materials for template intercalation;

[0054] For the above two-dimensional g-C 3 N 4 The carbon material intercalated by the template is fully ground, and a second high-temperature heat treatment is performed at a nitrogen atmosphere with a heating rate of 5°C / min and a carbonization temperature of 800°C to remove the template and obtain nitrogen-doped carbon nanosheets.

Embodiment 2

[0056] The preparation method of nitrogen-doped carbon nanosheets is the same as in Example 1, except that the carbon source is pitch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com