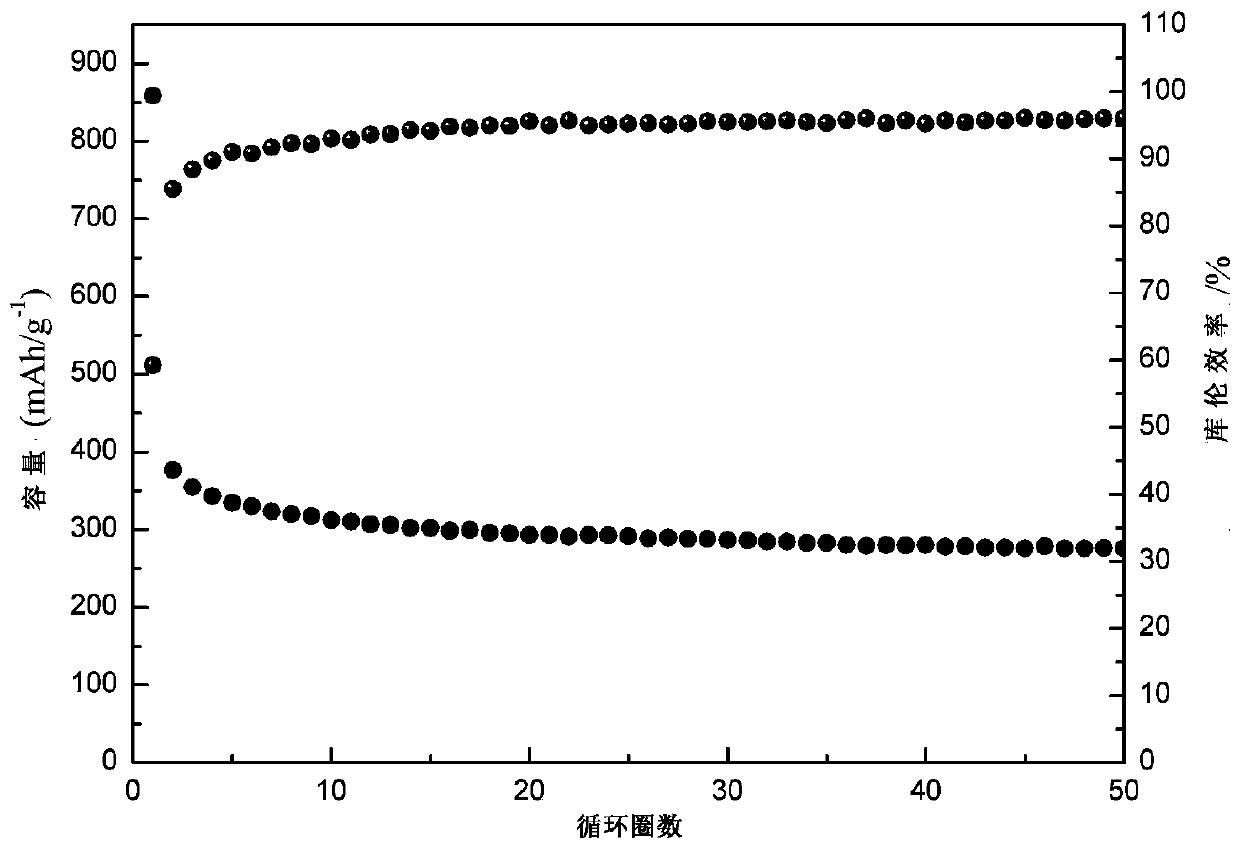

A carbon nanosheet material and its preparation and application in sodium-ion batteries

A carbon nanosheet and nanosheet technology, applied in the field of sodium ion batteries, can solve the problems of poor performance cycle stability, fast capacity decay, limited application, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Stir 20mL of 1.0mol / L nickel nitrate solution, 0.5mL of polyethylene glycol (molecular weight 600, 0.02mol) and 0.5mL of 1mol / L sodium hydroxide to carry out hydrothermal reaction. The holding temperature is 180°C and the holding time is 24h. Then wash with deionized water for 3 times, then wash with absolute ethanol for 2 times, and then dry in a vacuum oven at 60° C. for 10 h to obtain metal nanosheets. Put 0.08g metal nanosheets (0.001mol) in 200mL of Tris buffer solution with 8.8g dopamine (0.05mol) and 6.63g lysine (0.045mol), adjust the pH value to 8.5, let stand for 12h, after pumping Filter, wash and dry to obtain a carbon nitrogen-metal nanosheet precursor. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 1000°C, the carbonization time was 2h, and the heating rate was 2°C / min. Subsequently, the high-temperature carbonized product was repeatedly washed with dilute acid solution and water, then placed at 50° C., and vacuu...

Embodiment 2

[0068] Stir 20mL of 1.0mol / L copper nitrate solution, 0.5mL of polyethylene glycol (molecular weight: 600, 0.02mol) and 0.5mL of 1mol / L sodium hydroxide to carry out hydrothermal reaction at 160°C for 24 hours. Then wash with deionized water for 3 times, then wash with absolute ethanol for 2 times, and then dry in a vacuum oven at 60° C. for 10 h to obtain metal nanosheets. Put 0.8g of metal nanosheets (0.01mol) in 200mL of Tris buffer solution with 8.8g of dopamine (0.05mol) and 5.17g of asparagine (0.04mol), adjust the pH value to 8.5, let it stand for 16h, after pumping Filter, wash and dry to obtain a carbon nitrogen-metal nanosheet precursor. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 1000°C, the carbonization time was 2h, and the heating rate was 2°C / min. Subsequently, the high-temperature carbonized product was repeatedly washed with dilute acid solution and water, then placed at 50° C., and vacuum-dried for 8 hours. A ca...

Embodiment 3

[0070] Stir 20mL of 1.0mol / L ferric nitrate solution, 0.5mL of polyethylene glycol (molecular weight 600, 0.02mol) and 0.5mL of 1mol / L sodium hydroxide to carry out hydrothermal reaction. The holding temperature is 160°C and the holding time is 16h. Then wash with deionized water for 3 times, then wash with absolute ethanol for 2 times, and then dry in a vacuum oven at 60° C. for 10 h to obtain metal nanosheets. 0.08g metal nanosheets (0.005mol) were placed in 200mL Tris buffer solution with 8.8g dopamine (0.05mol) and 2.09g aspartic acid (0.02mol), and the pH value was adjusted to 8.5. Suction filtration, washing and drying to obtain a carbon nitrogen-metal nanosheet precursor. The precursor was carbonized under nitrogen atmosphere, the carbonization temperature was 900°C, the carbonization time was 2h, and the heating rate was 2°C / min. Subsequently, the high-temperature carbonized product was repeatedly washed with dilute acid solution and water, then placed at 50° C., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com