Method for preparing high-nitrogen-doped graphitized porous carbon material by metal nitrate catalytic carbonization method

A nitrate-catalyzed carbon and porous carbon material technology, applied in chemical instruments and methods, carbon compounds, non-metallic elements, etc., can solve the problems of limiting the application of nitrogen-doped carbon materials, low nitrogen doping content, and complicated preparation steps, etc. Achieve the effects of excellent supercapacitor performance, high nitrogen doping content, and low fabrication cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

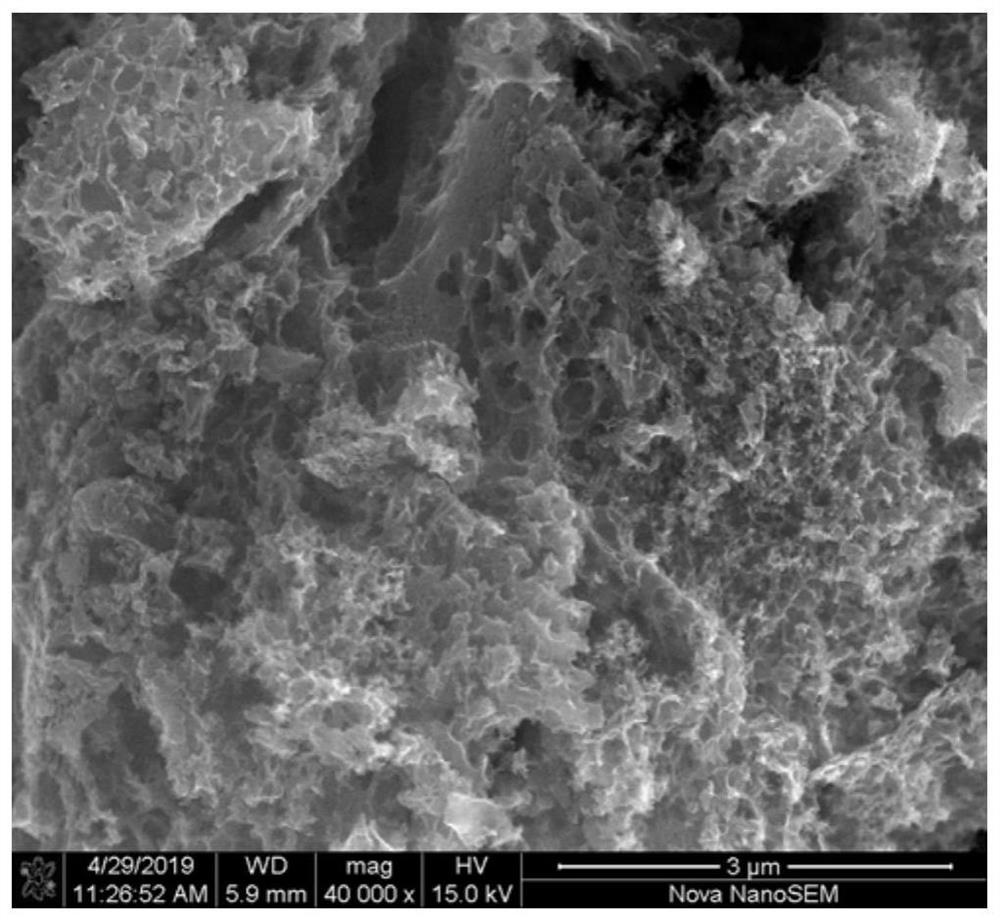

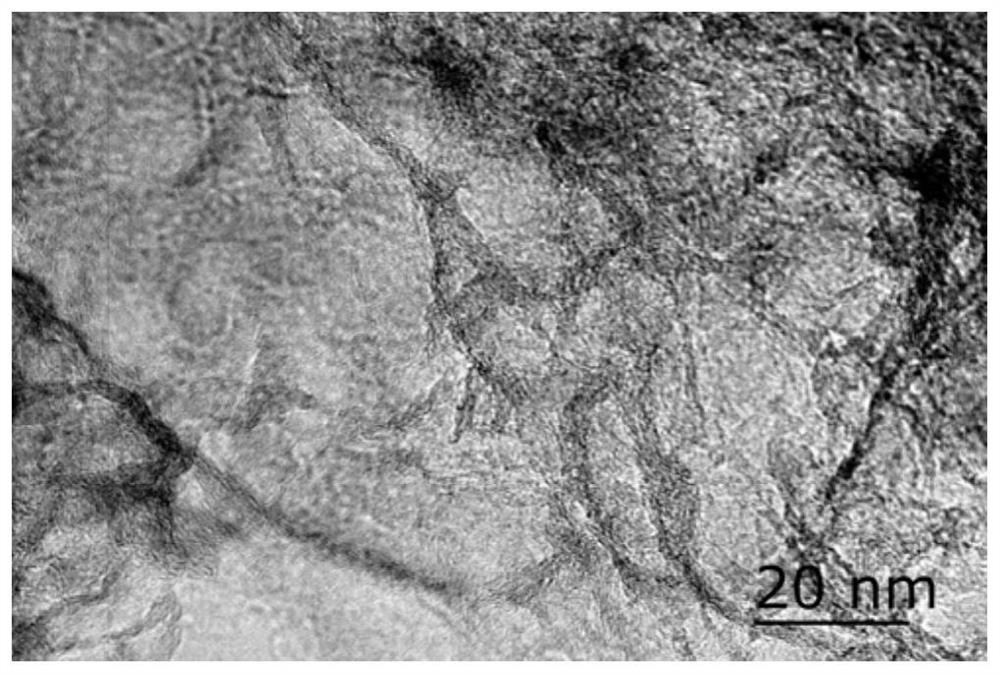

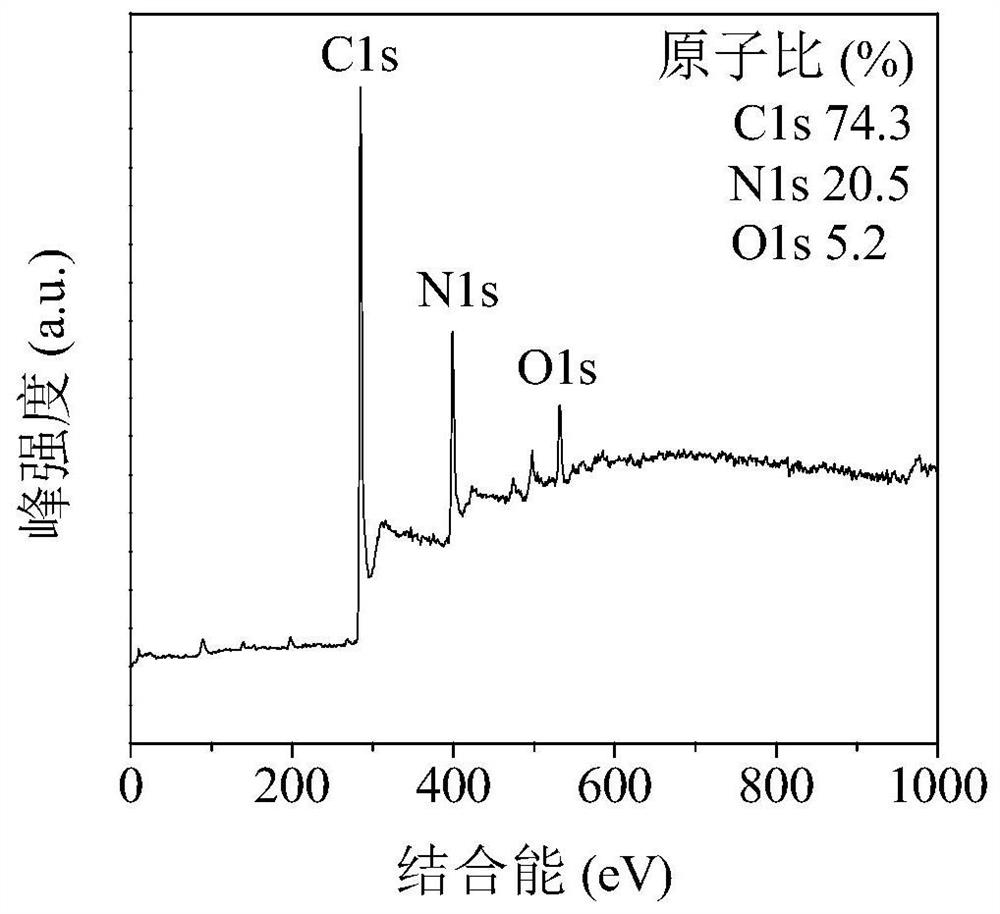

[0020] Example 1: Weigh 10g of dicyandiamide and dissolve it in 100ml of 70°C constant temperature distilled water, then weigh 5g of zinc nitrate hexahydrate and dissolve it in the above constant temperature solution of dicyanodiamine and stir it dynamically. After stirring for 5min, place the solution Dynamically stir and evaporate in a constant temperature oil bath at 70°C until the water is evaporated and dried to obtain a solid substance. After the solid is fully ground to powder, put it into a porcelain boat and place it in a tube furnace, and feed it at a rate of 10ml / min Nitrogen, while raising the temperature of the tube furnace to 250°C at a heating rate of 10°C / min, and keeping it at 250°C for 0.5h, then continuing to heat up to 900°C and constant temperature carbonization for 1 hour to obtain a solid product, and finally washing, After drying and grinding, a nitrogen-doped graphitized porous carbon material is obtained. The prepared nitrogen-doped porous carbon mate...

Embodiment 2

[0022] Example 2: Weigh 10g of dicyandiamide and dissolve it in 100ml of 70°C constant temperature distilled water, then weigh 5g of nickel nitrate hexahydrate and dissolve it in the above constant temperature solution of dicyanodiamine and stir it dynamically. After stirring for 5min, place the solution Dynamically stir and evaporate in a constant temperature oil bath at 70°C until the water is evaporated and dried to obtain a solid substance. After the solid is fully ground to powder, put it into a porcelain boat and place it in a tube furnace, and feed it at a rate of 10ml / min Nitrogen, while raising the temperature of the tube furnace to 250°C at a heating rate of 10°C / min, and keeping it at 250°C for 0.5h, then continuing to heat up to 900°C and constant temperature carbonization for 2 hours to obtain a solid product, and finally washing, After drying and grinding, a nitrogen-doped graphitized porous carbon material is obtained.

[0023] Figure 5 It is the SEM picture o...

Embodiment 3

[0024] Example 3: Weigh 10g of dicyandiamide and dissolve it in 100ml of 70°C constant-temperature distilled water, then weigh 5g of ferric nitrate nonahydrate and dissolve it in the above-mentioned constant temperature solution of dicyanodiamine and stir dynamically. After stirring for 5min, place the solution Dynamically stir and evaporate in a constant temperature oil bath at 70°C until the water is evaporated and dried to obtain a solid substance. After the solid is fully ground to powder, put it into a porcelain boat and place it in a tube furnace, and feed it at a rate of 10ml / min Nitrogen, while raising the temperature of the tube furnace to 250°C at a heating rate of 10°C / min, and keeping it at 250°C for 0.5h, then continuing to heat up to 900°C and constant temperature carbonization for 1 hour to obtain a solid product, and finally washing, After drying and grinding, a nitrogen-doped graphitized porous carbon material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com