A kind of nitrogen-doped graphene and its preparation method and application

A nitrogen-doped graphene, nitrogen content technology, applied in the field of material science, can solve the problems of difficult electrode materials, poor conductivity, poor conductivity, etc., and achieves low equipment requirements, high nitrogen doping content, and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

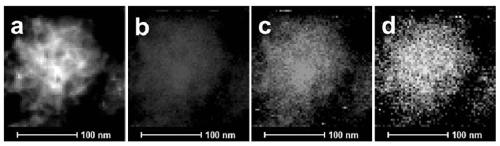

Image

Examples

preparation example Construction

[0035] In the present invention, the cyanamide compound can be purchased from commercial sources or prepared by itself. In one example, the preparation method of copper cyanamide includes: hydrolyzing cuprous chloride in ammonia water and reacting cyanamide, the particle size of copper cyanamide nanoparticles can be regulated by controlling the reaction conditions, and the specific control method can be adopted in the field known technology.

[0036]The above cyanamide compound needs to be dried at 120°C before use to fully remove the possible water vapor, and then placed in a quartz tube. Specifically, the dried cyanamide compound can be directly powdered or compressed into tablets, and the total weight should not exceed 1 g, so as to prevent the gas pressure generated by decomposition from being too high to cause the quartz tube to break. Add the cyanamide compound into the quartz tube with one end open, and vacuum seal the tube. In the present invention, the degree of vac...

Embodiment 1

[0056] (1) Take a certain amount of nickel hydrocyanamide (0.2g), grind the powder evenly in a mortar and press into tablets;

[0057] (2) Place hydrogen cyanamide nickel in a quartz tube with an open end, connect a vacuum pump to make the vacuum less than 10Pa, and then use a hydrogen-oxygen flame gun to melt and seal the open end of the quartz tube;

[0058] (3) Place the vacuum-tight quartz tube in a muffle furnace, raise the temperature from 30°C to 700°C at a rate of 1°C / min, and keep it warm for 2 hours, so that the cyanamide precursor is pyrolyzed to obtain nitrogen-doped graphene and complexes of transition metals;

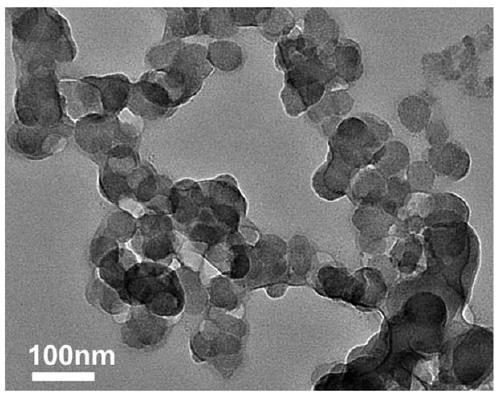

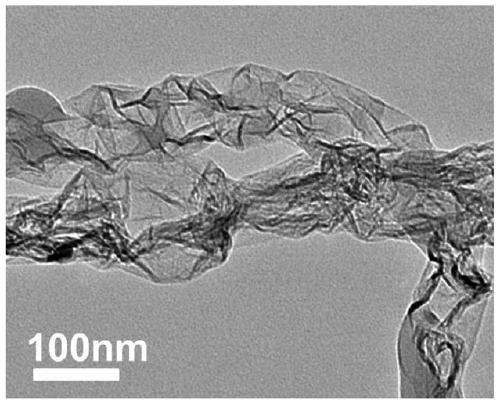

[0059] (4) Take it out after cooling with the furnace, put the obtained compound into the etching solution of 1M dilute hydrochloric acid, remove the nickel metal particles, add deionized water to wash and suction filter until the filtrate is neutral, and dry to obtain the nitrogen Doped graphene, its structure is a bamboo-shaped tubular structure such as...

Embodiment 2

[0062] (1) Take a certain amount of nickel hydrocyanamide (0.2g), grind the powder evenly in a mortar and press into tablets;

[0063] (2) Place hydrogen cyanamide nickel in a quartz tube with an open end, connect a vacuum pump to make the vacuum less than 20Pa, and then use a hydrogen-oxygen flame gun to melt and seal the open end of the quartz tube;

[0064] (3) Place the vacuum-tight quartz tube in a muffle furnace, raise the temperature from 30°C to 800°C at a rate of 1°C / min, and keep it warm for 2 hours, so that the cyanamide precursor is pyrolyzed to obtain nitrogen-doped graphene and complexes of transition metals;

[0065] (4) Take it out after cooling with the furnace, put the obtained compound into the etching solution of 1M dilute hydrochloric acid, remove the nickel metal particles, add deionized water to wash and suction filter until the filtrate is neutral, and dry to obtain the nitrogen Doped graphene, its structure is a bamboo-shaped tubular structure, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com