A kind of superhydrophobic film and preparation method thereof

A super-hydrophobic, thin-film technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of expensive raw materials, limited applications, and harsh preparation conditions for super-hydrophobic membranes, and achieve increased market promotion, easy operation, and environmental protection. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

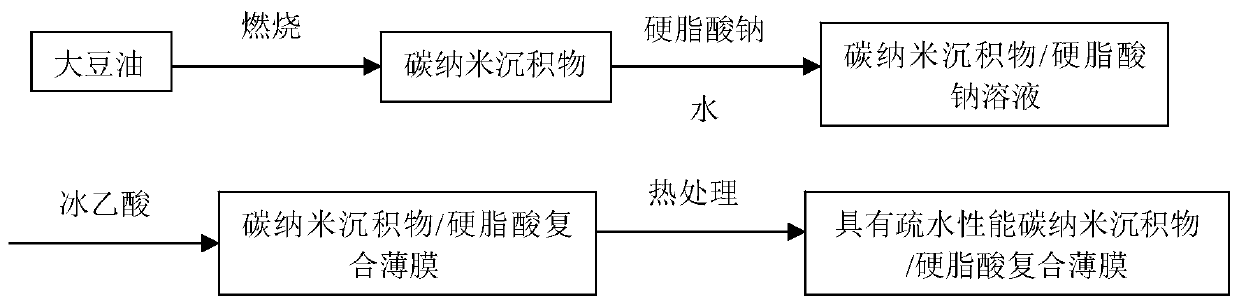

[0042] A kind of preparation method of simple and economical superhydrophobic film comprises the following steps;

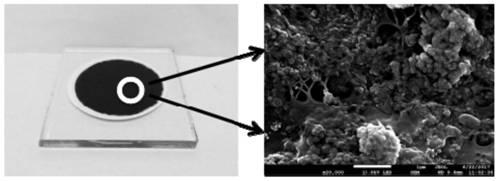

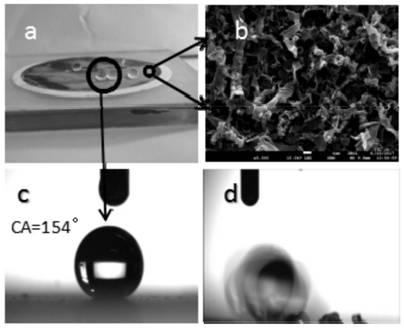

[0043] 1) Combusting soybean oil to obtain the preparation of carbon nano-deposits: at room temperature, put soybean oil into a porcelain boat and use cotton thread as a wick, and use a 500ml beaker as a receiving container for carbon nanoparticles after being ignited; the collected carbon nano-deposits After ball milling, put it into a vacuum oven for preservation;

[0044] 2) Mix 0.01 g of carbon nano-sediment and 0.02 g of sodium stearate, add 100 ml of deionized water and stir at 85°C for 10 min, and ultrasonically disperse the prepared solutions for 0.5 h to prepare carbon nano-sediment / hard Sodium fatty acid film precursor solution;

[0045] 3) Preparation of carbon nano-deposit / stearic acid composite precursor film: take 5ml of carbon nano-deposit / sodium stearate film precursor solution and sonicate for 10min, then add 0.1ml of glacial acid and sonicate f...

Embodiment 2

[0048] A kind of preparation method of simple and economical superhydrophobic film comprises the following steps;

[0049] 1) Preparation of carbon nano-deposits obtained by burning rapeseed oil: at room temperature, put rapeseed oil into a porcelain boat and use cotton thread as a wick, and use a 500ml beaker as a receiving container for carbon nanoparticles after being ignited; the collected carbon After the nano-deposits are ball-milled, they are stored in a vacuum drying oven;

[0050] 2) Mix 0.01 g of carbon nano-sediment and 0.2 g of sodium stearate, add 100 ml of deionized water and stir at 50°C for 20 min, and disperse the prepared solution by ultrasonic at 500 Hz for 1 h to prepare carbon nano-sediment / hard Sodium fatty acid film precursor solution;

[0051] 3) Preparation of carbon nano-deposit / stearic acid composite precursor film: take 10ml of carbon nano-deposit / sodium stearate film precursor solution and sonicate at 500Hz for 100min, then add 5ml of glacial acid...

Embodiment 3

[0054] A kind of preparation method of simple and economical superhydrophobic film comprises the following steps;

[0055] 1) Preparation of carbon nano-deposits obtained by burning peanut oil: at room temperature, put peanut oil into a porcelain boat and use cotton thread as a wick, and use a 500ml beaker as a receiving container for carbon nanoparticles after being ignited; the collected carbon nano-deposits are ball milled Afterwards, put into the vacuum drying oven and preserve;

[0056] 2) Mix 0.1 g of carbon nano-sediment and 0.02 g of sodium stearate, add 100 ml of deionized water and stir at 90°C for 20 min, and disperse the prepared solution by ultrasonic at 50 Hz for 2 h to prepare carbon nano-sediment / hard Sodium fatty acid film precursor solution;

[0057] 3) Preparation of carbon nano-deposit / stearic acid composite precursor film: Take 5ml of carbon nano-deposit / sodium stearate film precursor solution and sonicate at 50Hz for 80min, then add 2ml of glacial acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com