A preparation method of anti-counterfeiting material responding to multiple optical signals regulated by spin conversion

A spin conversion and optical signal technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of anti-counterfeiting materials and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

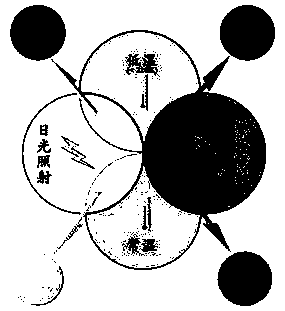

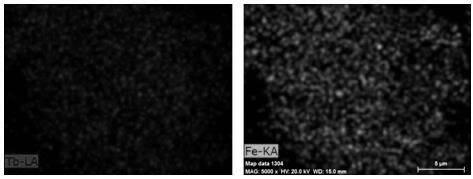

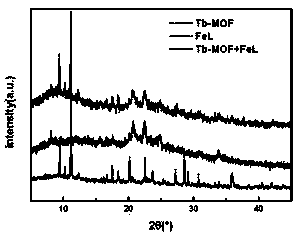

[0015] Weigh 48 mg FeL and 24 mg Tb-MOFs and mix them uniformly to obtain a composite material. The characteristics of the obtained composite material are: FeL is in a high spin state at room temperature, the composite material is white when irradiated by sunlight, and has strong green fluorescence when irradiated by ultraviolet light. However, at low temperature (< 210K), FeL is in a low-spin state, and the composite material is purple when irradiated by sunlight, and has green fluorescence when irradiated by ultraviolet light. It can be seen that when multiple signals such as temperature, ultraviolet light and visible light are input, the composite material can output three different color signals.

Embodiment 2

[0017] Weigh 56 mg FeL and 14 mg Tb-MOFs and mix them uniformly to obtain a composite material. The characteristics of the obtained composite material are: FeL is in a high spin state at room temperature, the composite material is white when irradiated by sunlight, and has strong green fluorescence when irradiated by ultraviolet light. However, at low temperature (< 210K), FeL is in a low-spin state, and the composite material is purple when irradiated by sunlight, and has green fluorescence when irradiated by ultraviolet light. It can be seen that when multiple signals such as temperature, ultraviolet light and visible light are input, the composite material can output three different color signals.

Embodiment 3

[0019] Weigh 60 mg FeL and 10 mg Tb-MOFs and mix them uniformly to obtain a composite material. The characteristics of the obtained composite material are: FeL is in a high spin state at room temperature, the composite material is white when irradiated by sunlight, and has strong green fluorescence when irradiated by ultraviolet light. However, at low temperature (< 210K), FeL is in a low-spin state, and the composite material is purple when irradiated by sunlight, and dark green when irradiated by ultraviolet light. It can be seen that when multiple signals such as temperature, ultraviolet light and visible light are input, the composite material can output four different color signals. This ratio is the best mixing ratio, and its output color difference is the most obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com