A Method for Improving Nitriding Layer Structure of 1cr13 Steel Membrane Lid Parts

A 1cr13, nitrided layer technology, applied in the field of heat treatment, can solve the problems that the infiltrated layer structure does not meet the rating standards or inspection requirements, cannot effectively improve the form and distribution of nitrides, and the brittleness of nitrided parts is large, so as to prevent surface oxidation. The effect of decarburization, gradual decrease of hardness gradient, and improvement of brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A method for improving the structure of the nitrided layer of the 1Cr13 stainless steel film-covered part is carried out according to the following steps:

[0020] ①Inspection: Process inspection is carried out on incoming parts, and the surface of the sample should be clean without excess.

[0021] ②Vacuum nitrogen removal: before heating, the pressure in the vacuum chamber is pumped to 6.7×10 -2 Pa, heating and holding for a certain period of time (see Table 1 for details), during heating and holding, the pressure in the vacuum chamber should not exceed 6.7×10 -2 Pa, after the heat preservation is over, fill it with argon gas at 0.3MPa and cool it to below 80°C.

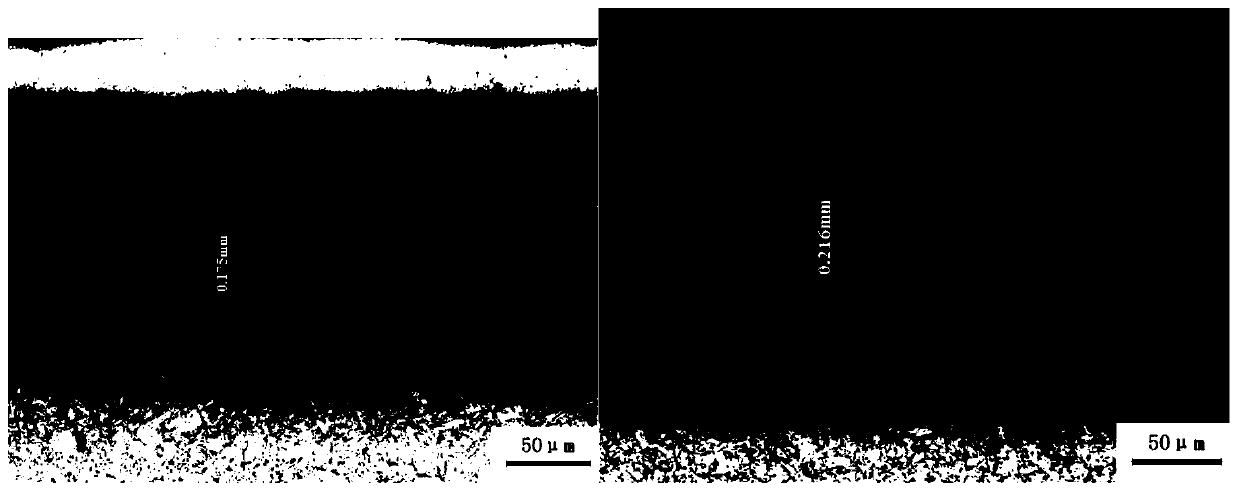

[0022] ③ Inspection: Check the structure and hardness of the nitrided layer, the hardness of the nitrided surface is HR15N ≥ 88; the structure of the nitrided layer is better than that of semi-continuous fine network nitride.

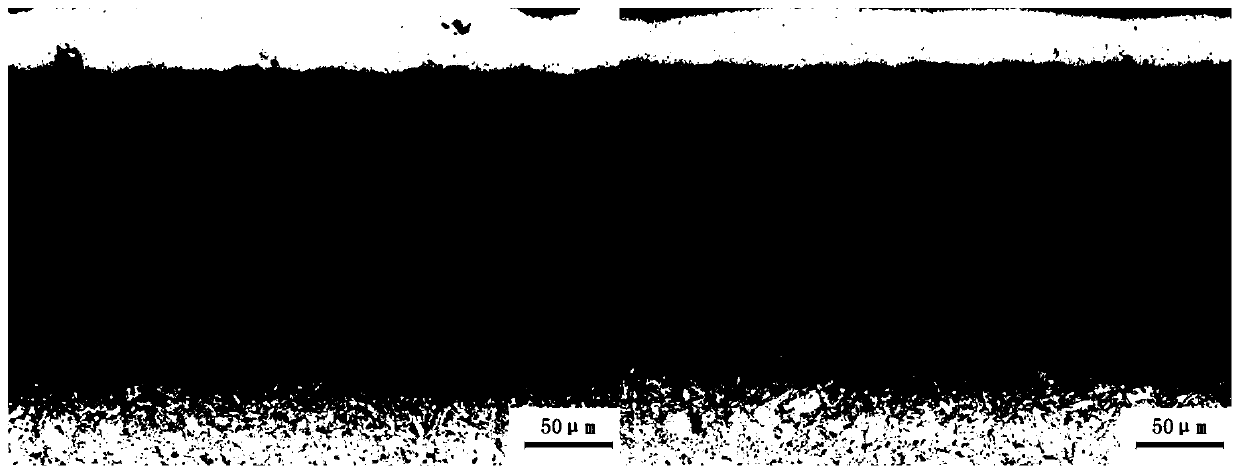

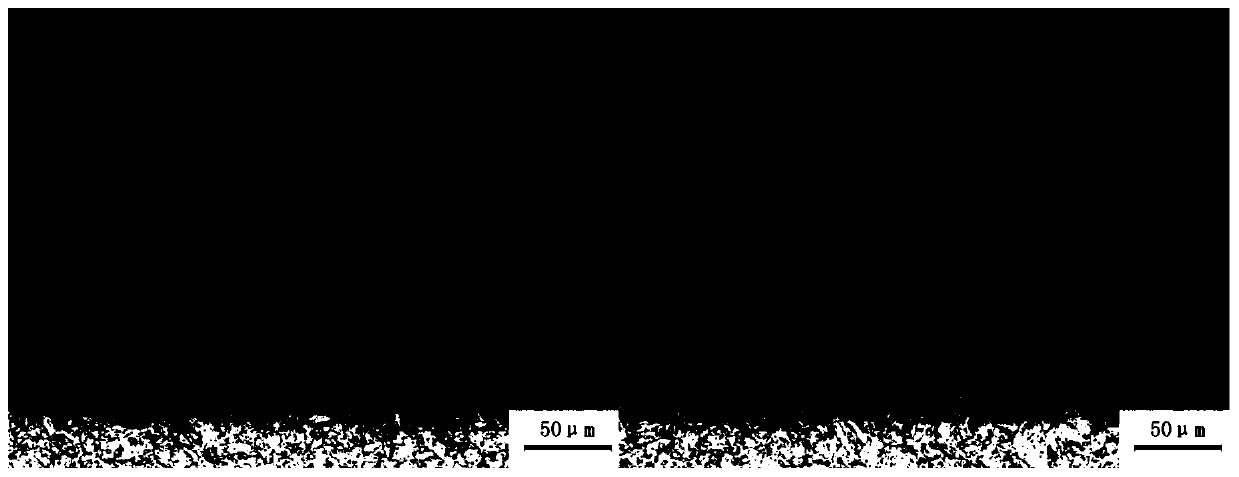

[0023] Organizational observation: use a metallographic microscope to observe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com