A kind of preparation method of high temperature protective coating

A protective coating and high temperature technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of increasing the surface roughness of the coating, consuming the Al content of the coating, etc., and achieve the removal of surface roughness , optimize the distribution of coating elements, and improve the effect of high temperature service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

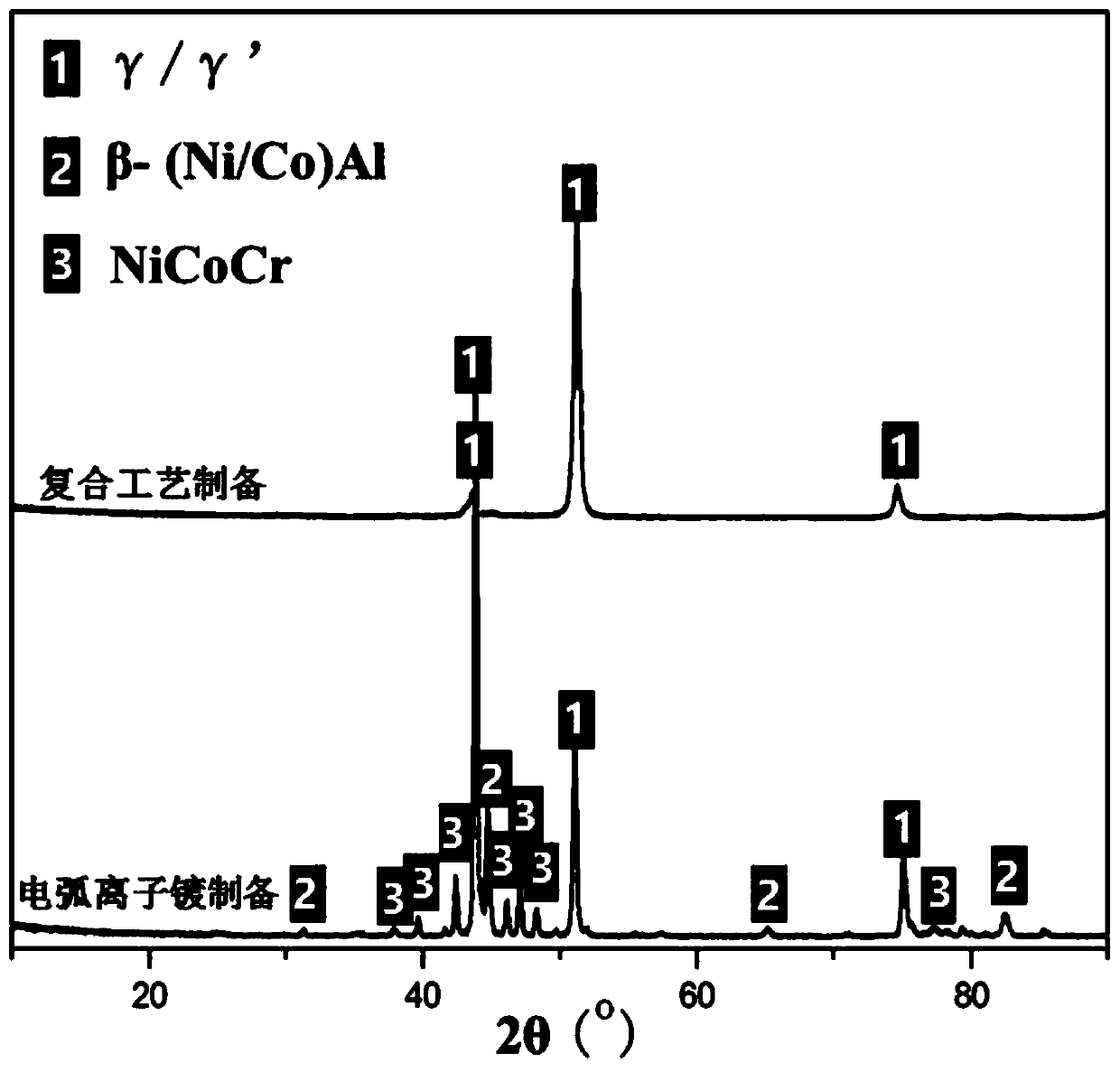

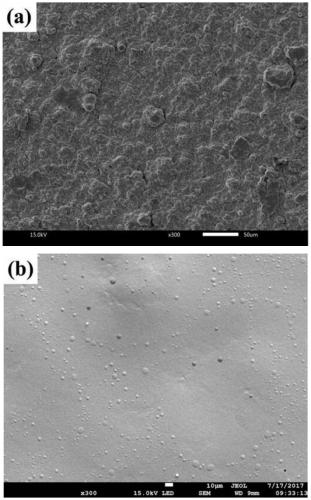

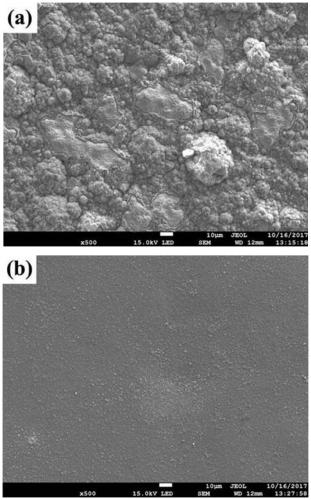

[0024] The following is an example of the coating prepared by the composite technology of arc ion plating and pulsed electron beam, and the specific preparation method of the composite technology is described in detail in conjunction with the accompanying drawings.

[0025] S1. After the superalloy substrate is pre-grinded, cleaned, and sandblasted, use arc ion plating technology to deposit NiCoCrAlYX (X=Hf+Si, Co 20%, Cr 28%, Al 10%, Y0 .8%, Si0.08%, Hf0.15%, Ni Bal.) high-temperature protective coating, the thickness is 30μm; choose according to the technical requirements of arc ion plating equipment: vacuum -3 Pa, arc current 60A, arc voltage 20V, pulse bias -300V;

[0026] S2. Carry out vacuum heat treatment (900°C, 4h) to the prepared NiCoCrAlYX coating, and the vacuum degree of the vacuum heat treatment furnace is 1×10 -3 Pa, the heating rate is controlled at 5°C·min -1 ;

[0027] S3. Perform HCPEB bombardment treatment on the NiCoCrAlYX coating after vacuum heat treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com