Construction method of cast-in-place pile

A construction method and cast-in-place pile technology, which are applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large mud discharge, low construction efficiency and high construction cost, and achieve high single pile bearing capacity and pile forming speed. Fast, low-noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

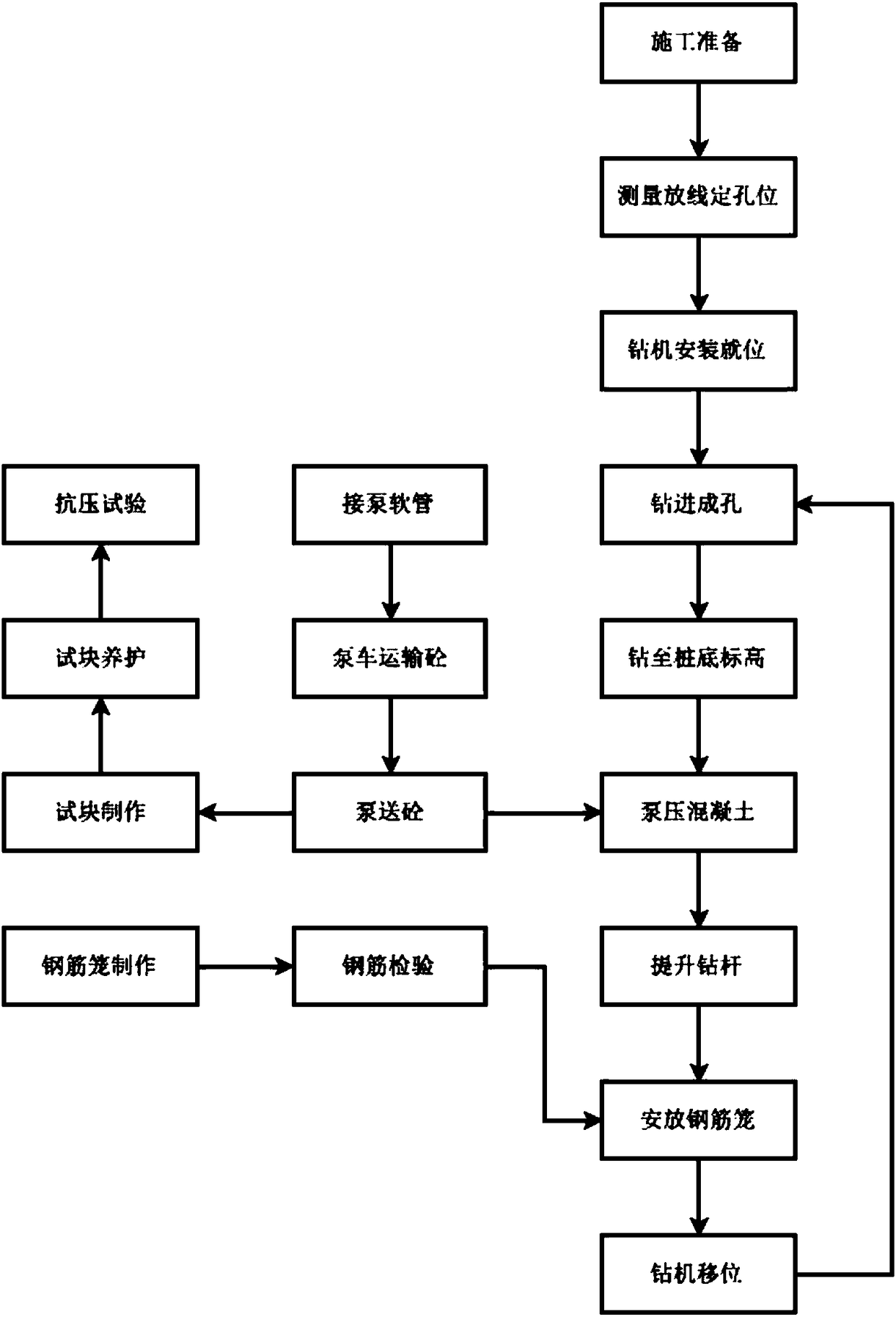

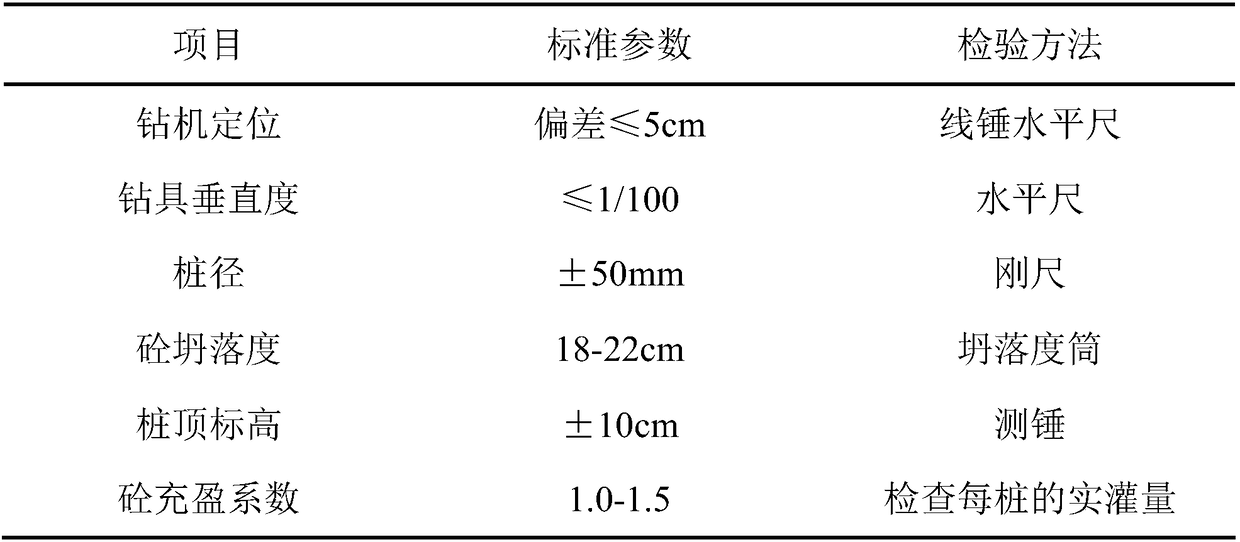

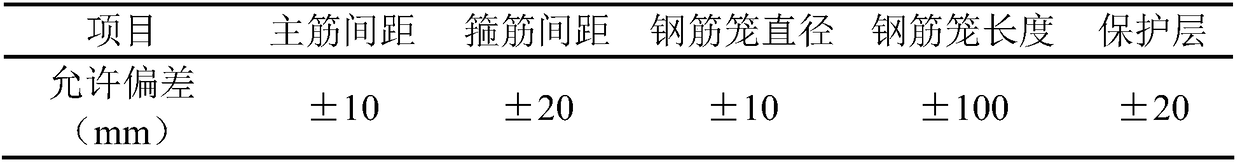

Method used

Image

Examples

Embodiment

[0053] Take the implementation of a pipe gallery in Beijing as an example. The construction method uses the open construction method, and the groove depth is 8-10 meters. It is a dangerous sub-item project and requires strict selection of foundation pit support methods.

[0054] Engineering, hydrogeological conditions:

[0055] The project is located in Tongzhou District. The engineering geological conditions of the construction site are relatively simple. The stratum deposition age and genetic type are divided into three types: artificial accumulation layer, recent sediment layer and Quaternary sediment layer, and according to stratum lithology and its physical and mechanical properties It is divided into 5 large layers and sub-layers according to engineering characteristics, which are described as follows:

[0056] Ⅰ Artificial accumulation layer (the first large layer)

[0057] The surface layer distribution of the proposed site is generally 0.40~1.70m thick artificially piled plai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com