Lithium-ion battery radiating structure and method based on phase-change microcapsule slurry

A lithium-ion battery, phase-change microcapsule technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of short-term overheating of batteries, low cooling efficiency of cooling systems, low cooling capacity, etc., to reduce the probability of occurrence, reduce The effect of battery overheating issues, improved lifespan and thermal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing:

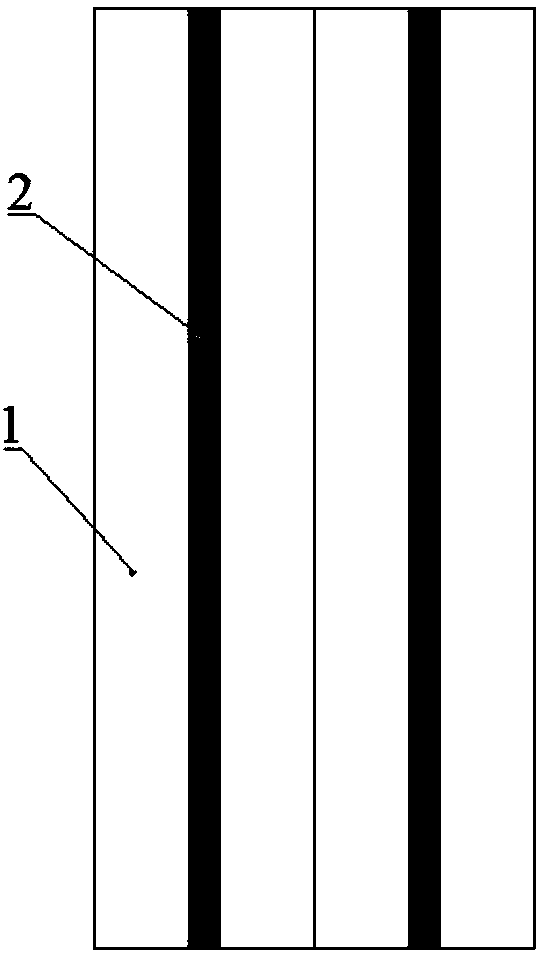

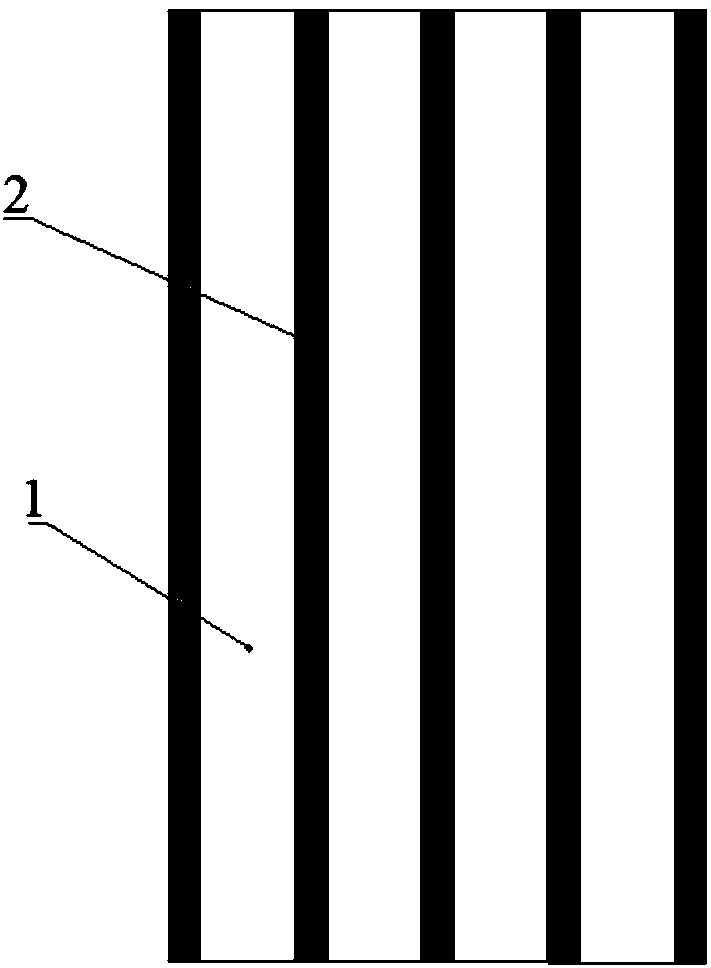

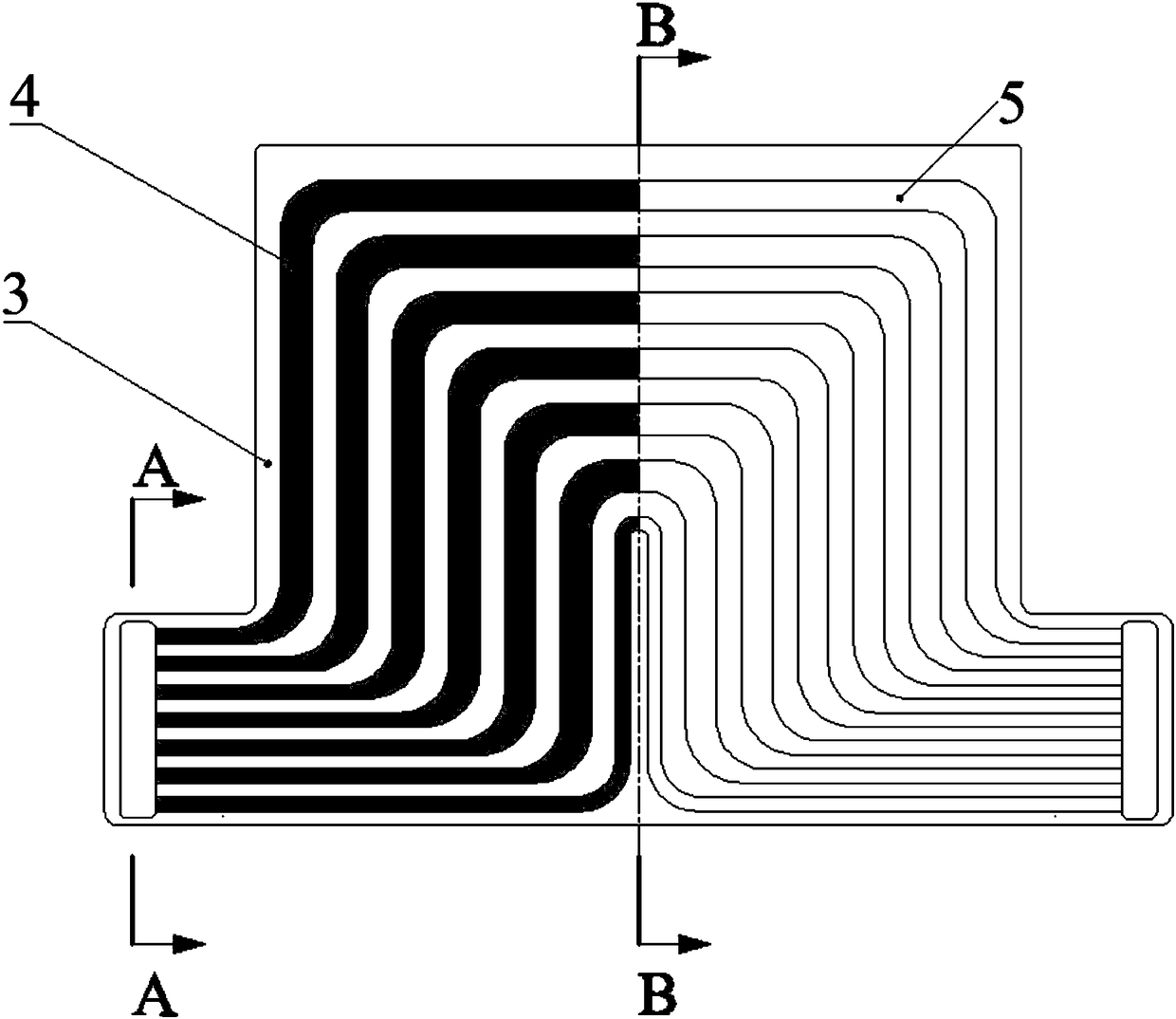

[0025] See Figure 1- Figure 4 , a lithium-ion battery heat dissipation structure based on phase-change microcapsule cooling slurry, including a lithium-ion battery 1 and a cooling plate 2; several cooling plates 2 are arranged in parallel, and the gap between the cooling plates 2 is provided with one or two layers of lithium The ion battery 1 forms the heat dissipation structure of the lithium battery pack; the cooling plate 2 is welded by two cooling plate substrate plates 3, and a number of cooling slurry flow channels 5 are formed inside; each cooling slurry flow channel 5 is arranged in the shape of a "several" , and the runners are parallel to each other; one end of the "ji"-shaped runner is the cooling slurry inlet, and the other end is the cooling slurry outlet; the "ji"-shaped runner is provided with a cooling slurry 4; the cooling slurry 4 is the mixed slurry of cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com