Oil injection device for milling machine

A technology of oiling device and milling machine, which is applied in the direction of metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of low degree of automation and large manual investment in lubricating oil filling, and achieve high degree of automation and low labor input Small and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

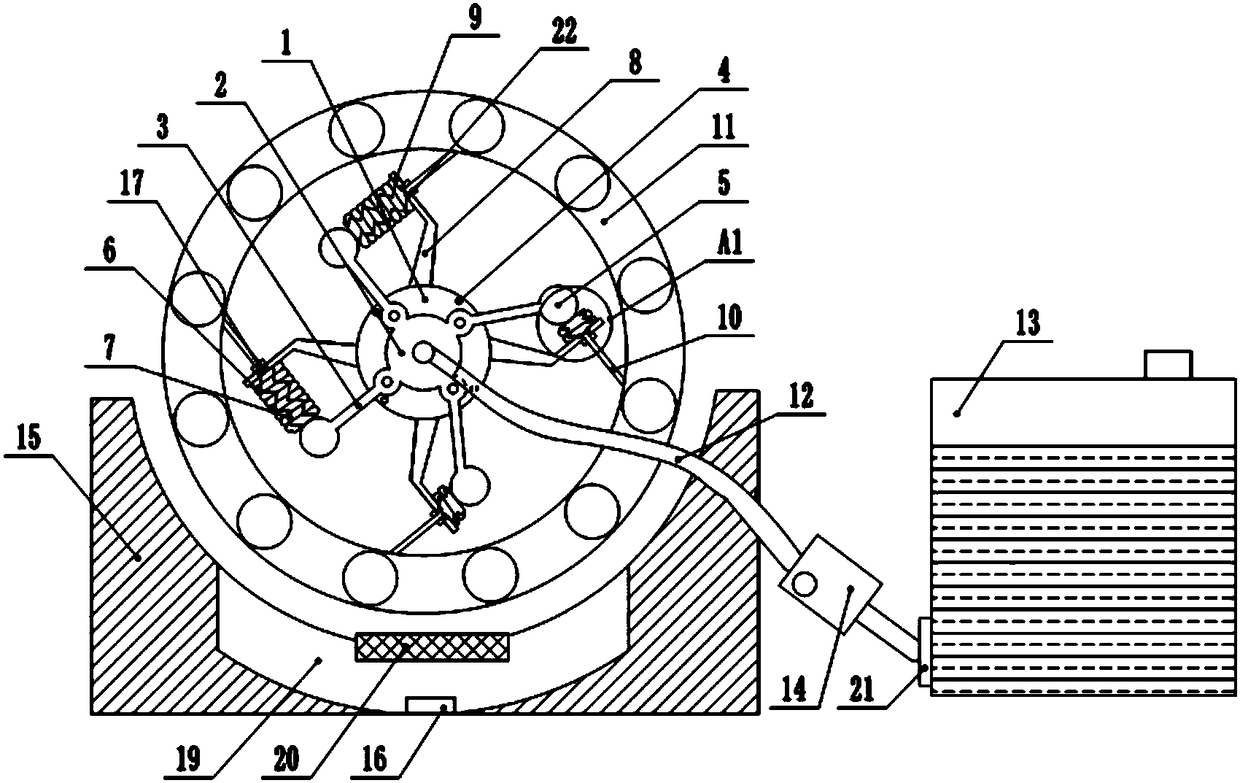

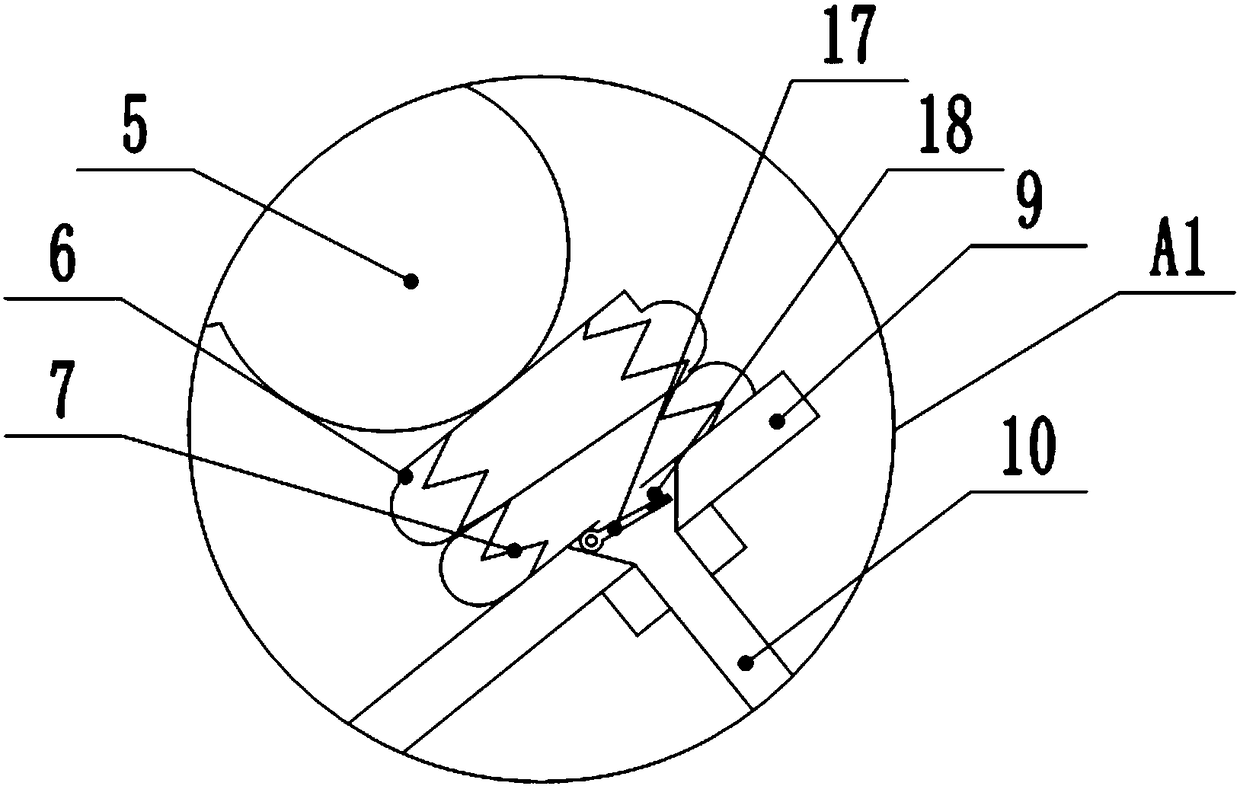

[0019] The reference signs in the accompanying drawings of the specification include: support seat 1, oil storage tank 2, oil outlet pipe 3, block 4, hollow pressure ball 5, oil storage bag 6, support spring 7, support rod 8, support plane 9, note Oil pipe 10, bearing 11, oil inlet pipe 12, lubricating oil tank 13, oil pump 14, oil receiving tank 15, recovery port 16, baffle plate 17, magnet 18, oil filter chamber 19, filter screen 20, first sealing ring 21, second sealing Circle 22.

[0020] Such as figure 1 , figure 2 As shown: the oil injection device for milling machine, including the injection mechanism, the injection mechanism includes a support base 1 coaxially connected with the bearing 11 of the milling machine, the support base 1 is fixedly connected with the oil storage tank 2, the oil storage tank 2 is made of rubber material, With elasticity, the oil stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com