Super-mirror high precision numerically controlled polishing machine

A high-precision, polishing machine technology, applied in the field of polishing machines, can solve problems such as spiral patterns, and achieve the effect of eliminating spiral patterns and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

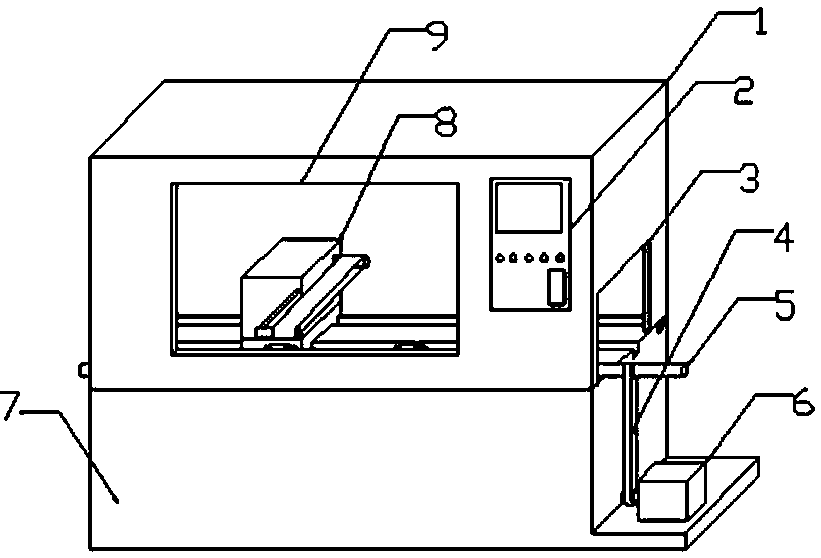

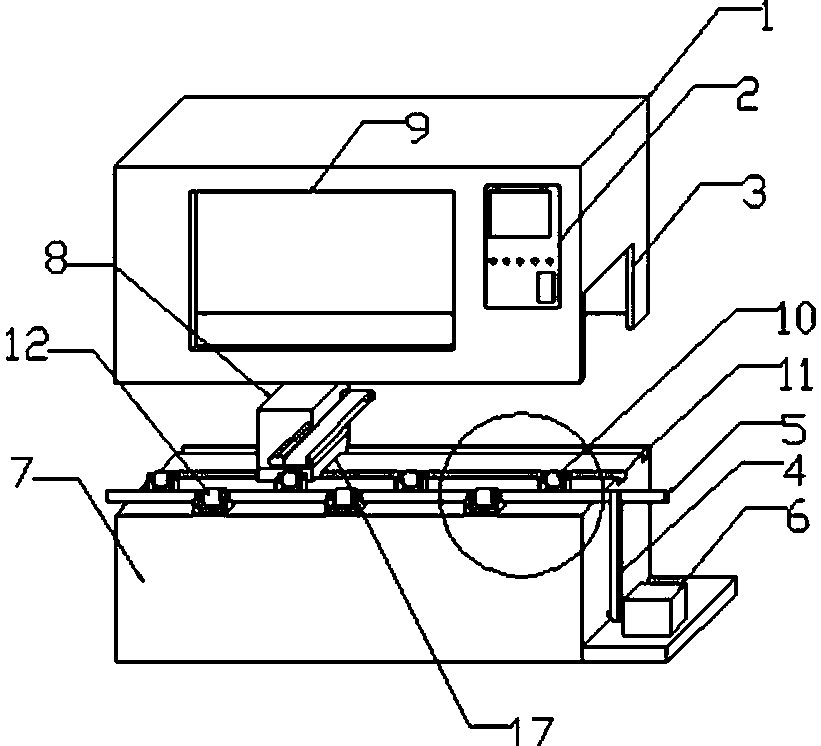

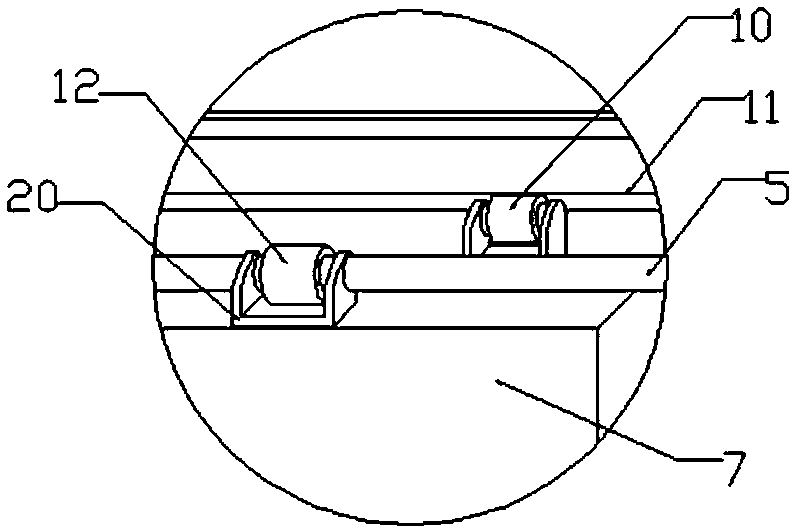

[0021] Example: such as Figure 1-6 As shown, a kind of ultra-mirror surface high-precision numerical control polishing machine of the present invention comprises lathe 7, and the top of machine tool 7 is provided with two fixed frame groups and two track grooves 11 successively, and two fixed frame groups are all made of several fixed frames 20 Composition, the slot of the fixed frame 20 of one of the fixed frame groups close to the track groove 11 is equipped with driven wheels 10, and the two sides of the fixed frame 20 of the other fixed frame group are connected with the connecting shaft 5 through interspersed connection, and the connecting shaft 5 is respectively provided with a first gear and several driving wheels 12, and several driving wheels 12 are all fixedly connected with connecting shaft 5, and several driving wheels 12 are all positioned in the groove of fixed frame 20, and one side of machine tool 7 is provided with Transmission motor 6, the second gear that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com