Sheet part machining process and device

A technology of parts processing and sheeting, which is applied in the field of sheet parts processing technology and devices, can solve problems such as difficulty in ensuring processing accuracy, reducing adsorption force, and high labor intensity, so as to ensure processing accuracy and surface quality, and improve heat dissipation. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

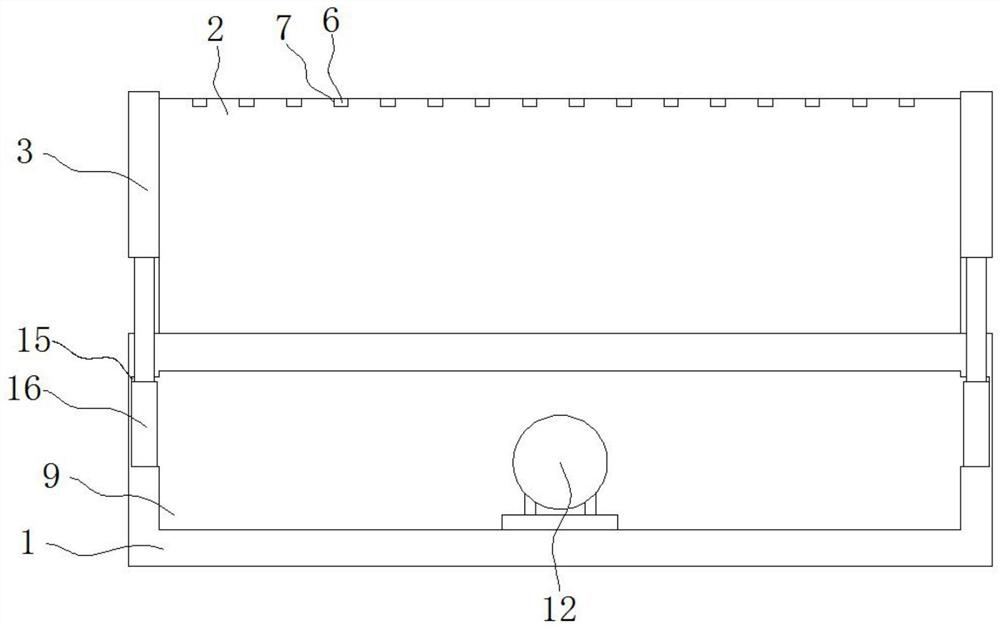

[0024] As a preferred embodiment of the present invention, the bottom of the collection tank 10 is fitted with a bottom cover 18 through external threads and internal threads.

[0025] As a preferred embodiment of the present invention, a water supply pipe 17 is fixedly installed on the front side of the base 1 , and one end of the water inlet pipe 13 is fixedly connected to the water supply pipe 17 .

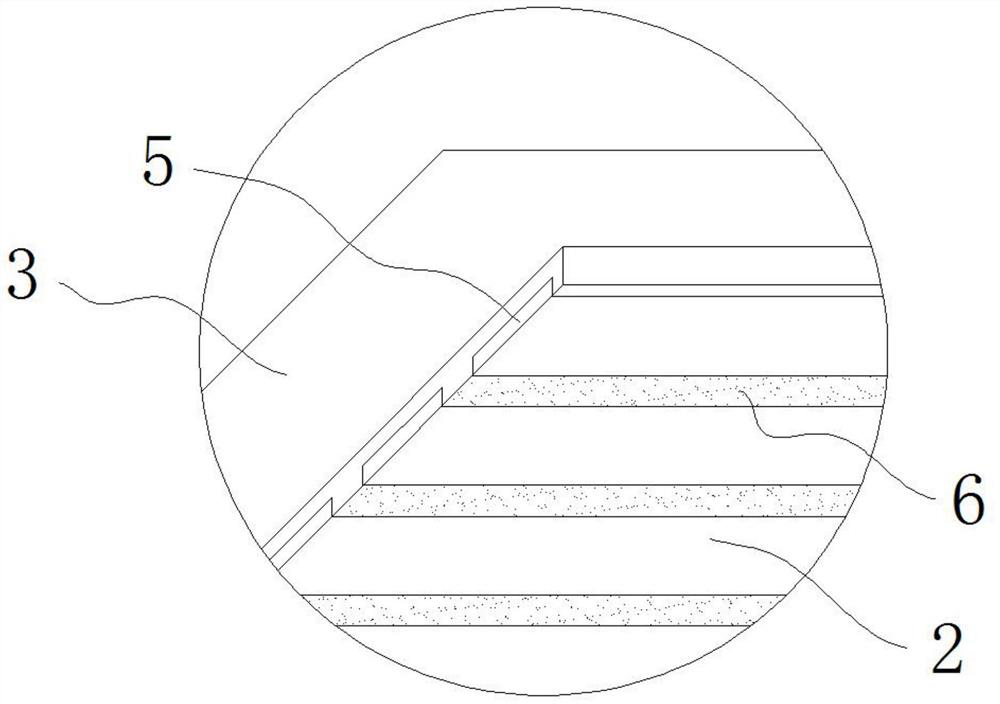

[0026] As a preferred embodiment of the present invention, the top of the strip plate 6 is on the same plane as the top of the magnetic table 2 .

[0027] As a preferred embodiment of the present invention, the top of the limiting frame 3 is higher than the top of the magnetic table 2 .

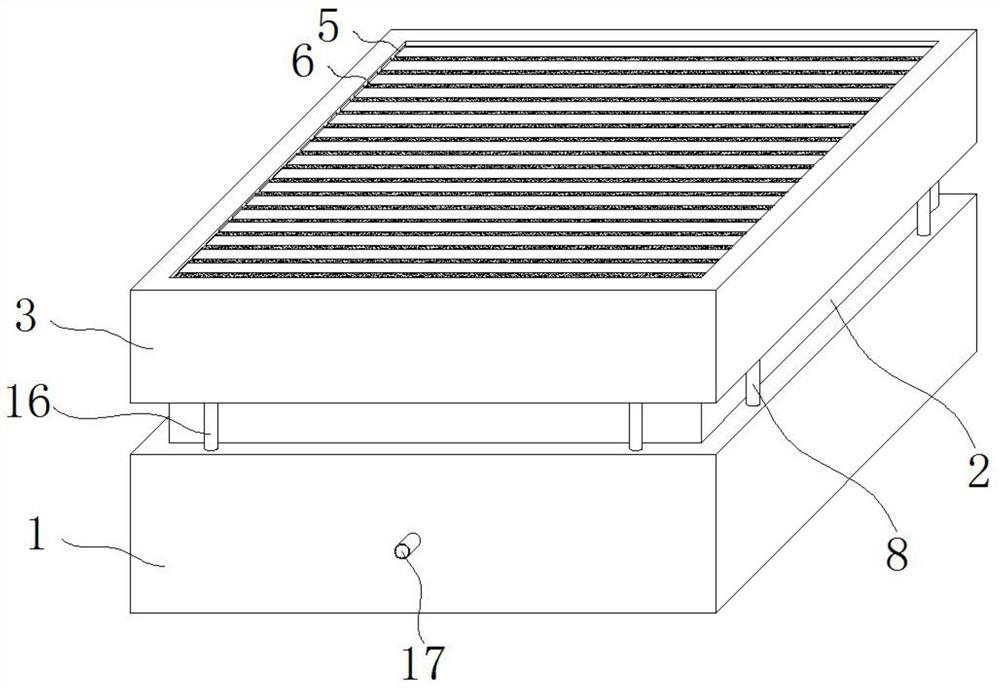

[0028]As a preferred embodiment of the present invention, when in use, replace the magnetic table on the grinding machine with this device, connect the water pump 12, the magnetic table 2 and the electric push rod 16 to the grinding machine control system, and place the sheet on the magnetic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com