Color master batch storage bin

A technology for storing silos and color masterbatch, which is applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., and can solve the problems of inability to drop, larger knots, and adhesion on the inner wall of the silo body and cone of the silo And other problems, to achieve the effect of improving the output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

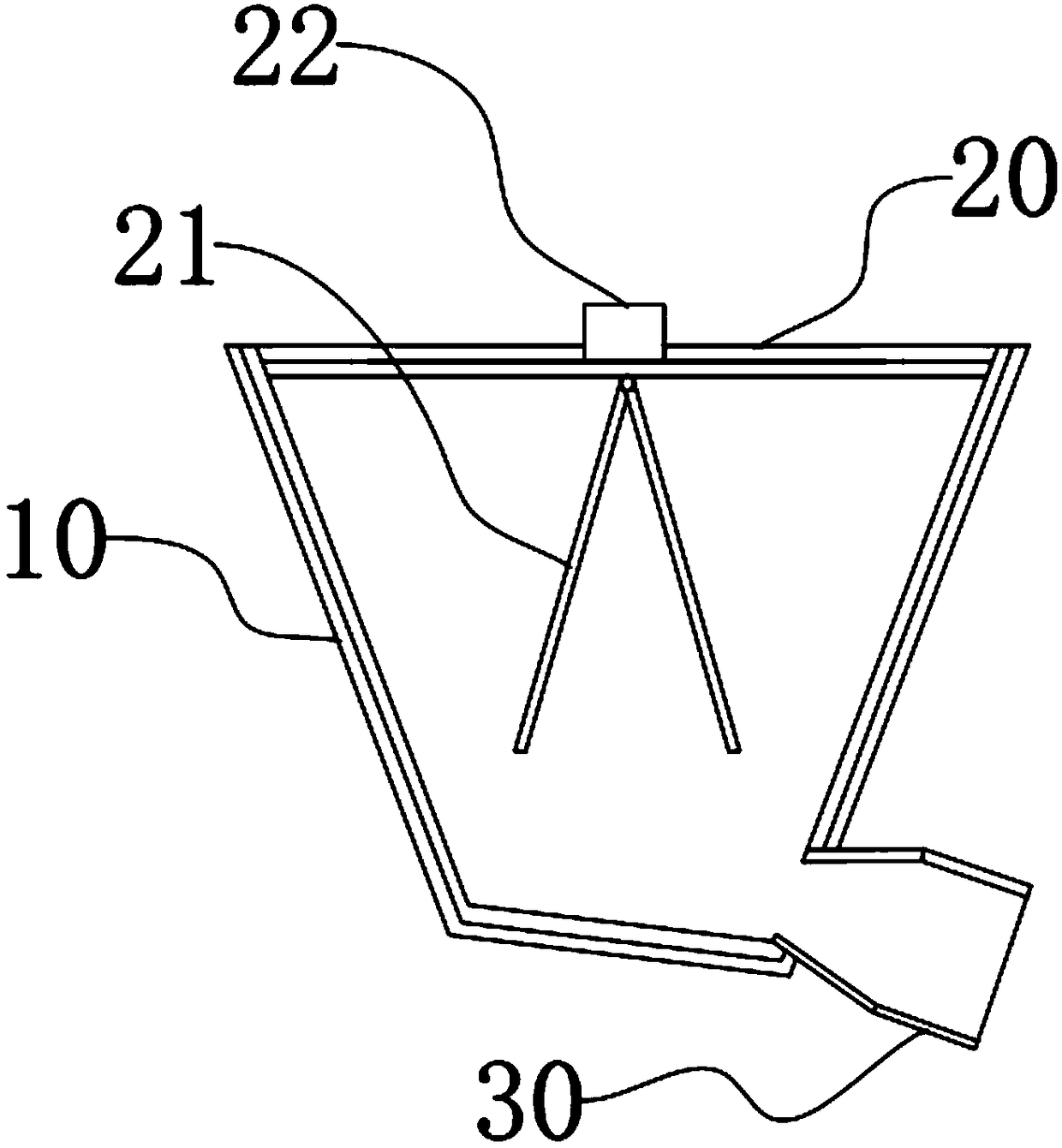

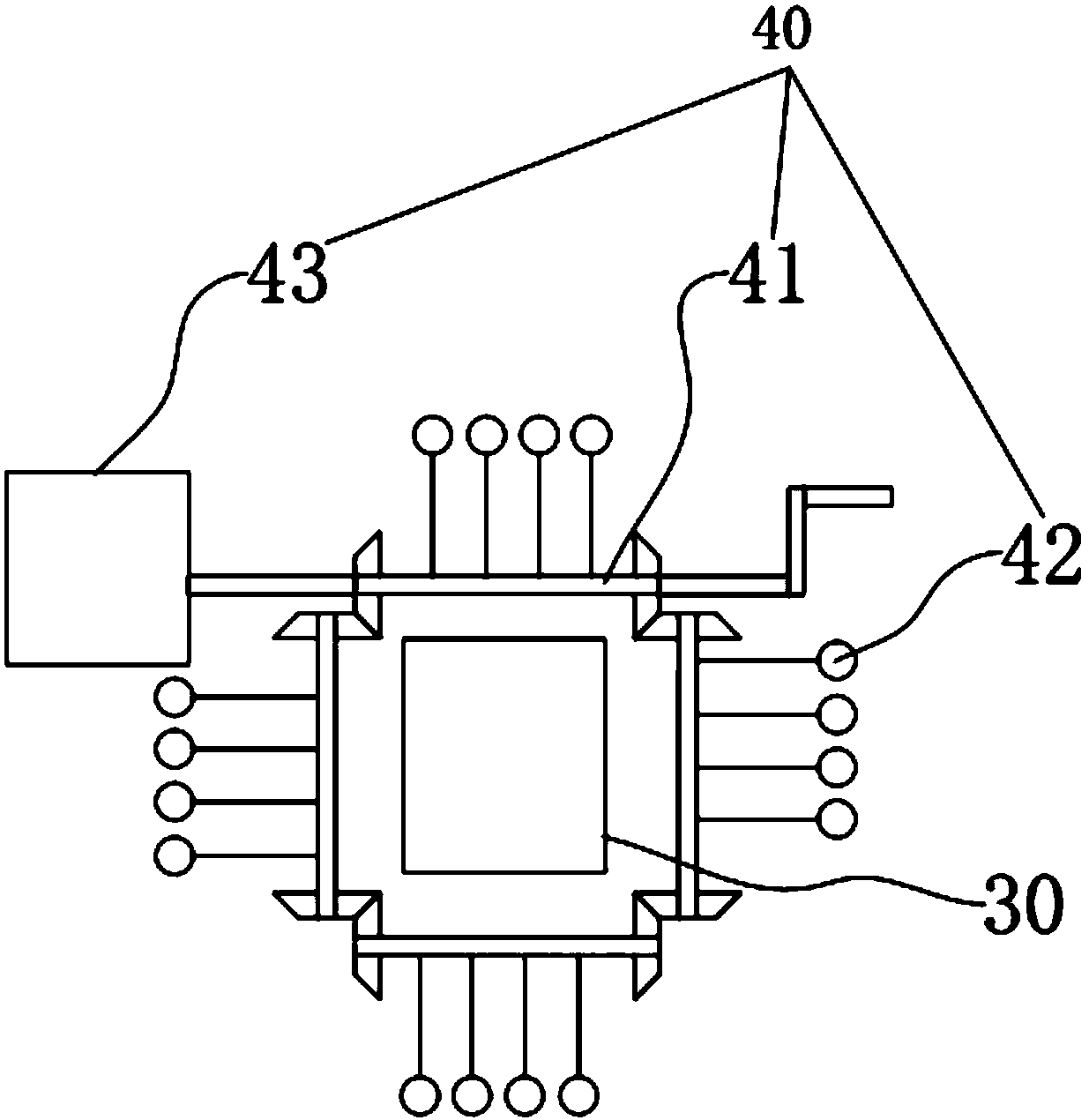

[0024] Please refer to figure 1 It is a structural schematic diagram of an embodiment of a color masterbatch storage bin in the present application. The storage bin includes a bin body 10, a bin cover 20, and a square discharge tube 30 located at one end of the bottom of the bin body 10; the inner...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap