Intelligent material conveying monitoring device

A transmission device and intelligent monitoring technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as noise pollution, poor stability of universal wheels, time-consuming and labor-intensive, etc., to prolong the normal service life and improve The effect of stable performance and avoiding noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

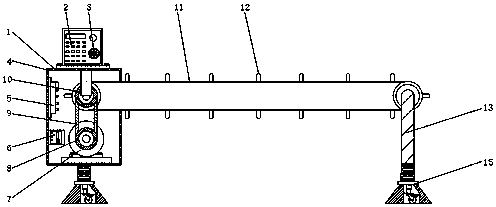

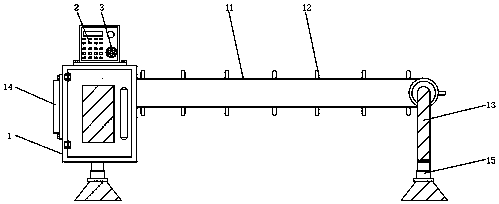

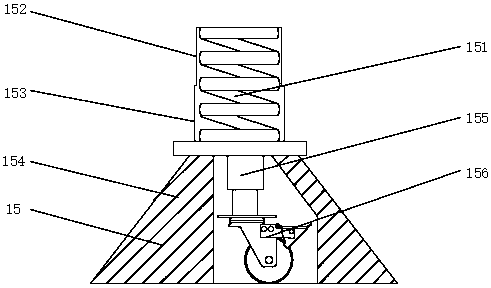

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an intelligent monitoring material conveying device, including a protective box 1, an SE300 control panel 2 is fixedly installed on the upper surface of the protective box 1, and a buzzer is embedded in the front surface of the SE300 control panel 2 3. Sound-absorbing cotton 4 is embedded inside the protective box 1, a temperature sensor 5 is fixedly installed on the inner side of the protective box 1, and an S7-200PLC is fixedly installed on the inner side of the protective box 1 close to the lower end of the temperature sensor 5 Controller 6, motor 7 is fixedly installed on the inner bottom of protective box 1, and the front surface of motor 7 is connected with driving wheel 8 in rotation, and driven wheel 10 is fixedly installed on the inside of protective box 1 close to the upper position of motor 7, and driving wheel 8 and the driven wheel 10 are connected by a belt 9, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com