Online detecting device and method for mechanical joint of whole core tape

A technology of mechanical joints and detection devices, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of low work efficiency and easy to make wrong judgments, and achieve high work efficiency, save manpower and material resources, and detect fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

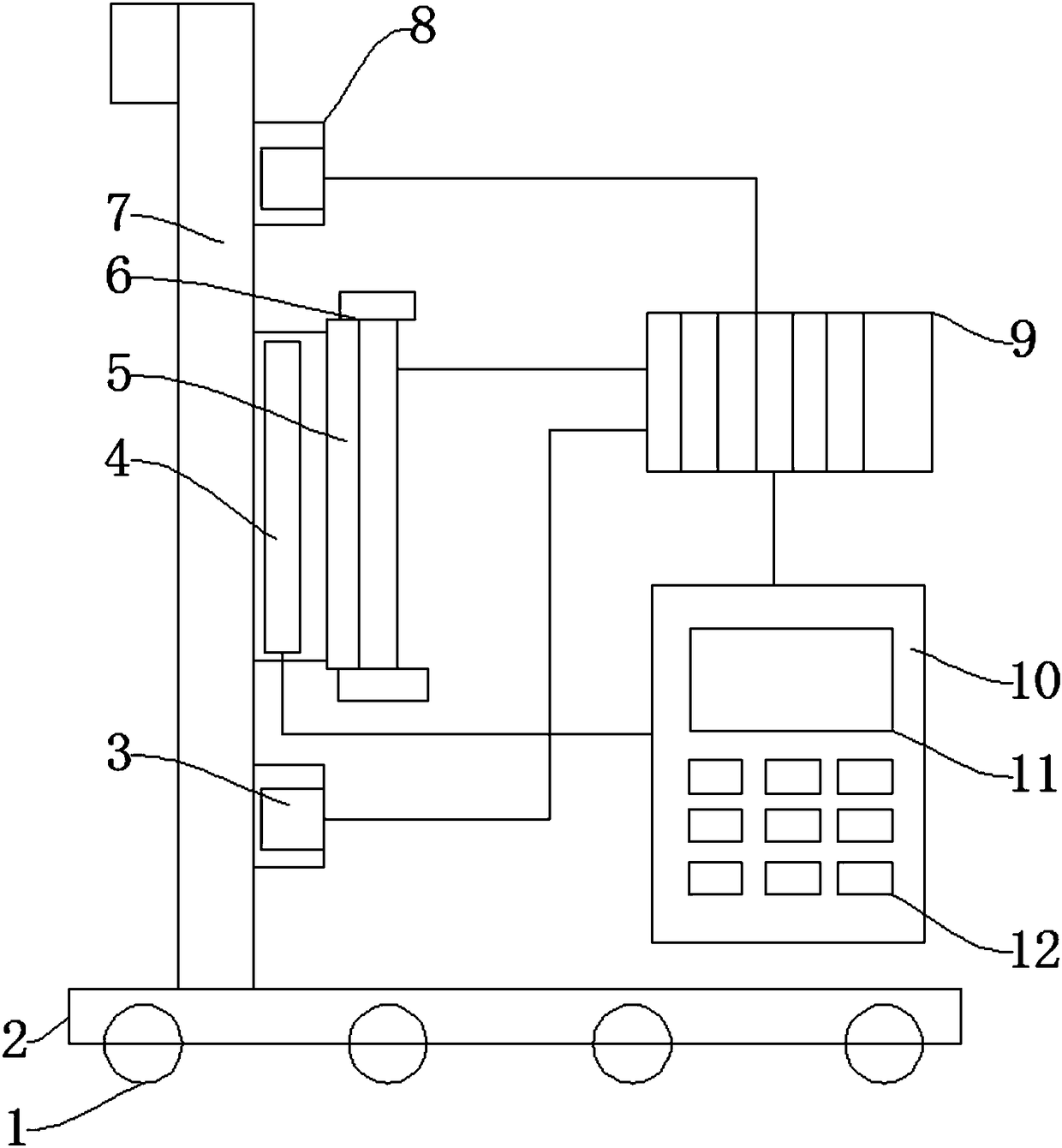

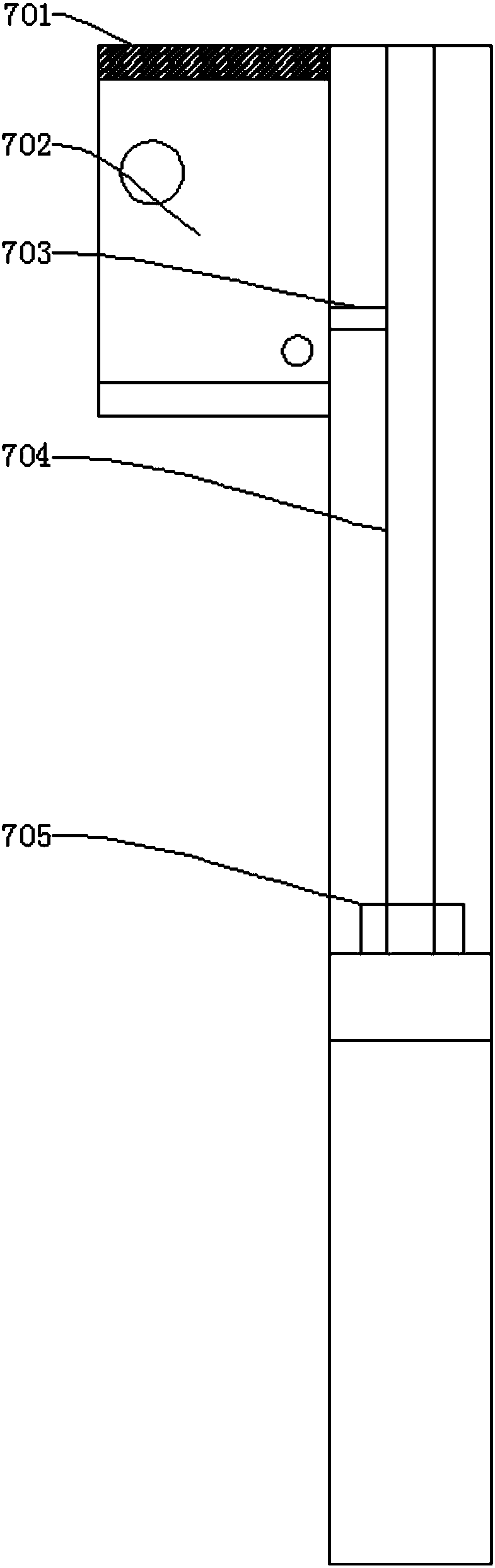

[0026] Such as Figure 1-Figure 4 As shown, an on-line detection device and method for mechanical joints of the whole core tape, including the bottom moving roller 1, the device base 2, the lower eddy current displacement sensor 3, the mechanical joint placement hole 4, the joint The distance detector 6, the support back plate 7, the upper eddy current displacement sensor 8, the device base 2 is arranged above the bottom moving roller 1, and the lower eddy current displacement sensor is arranged above the device base 2 device 3, the mechanical joint placement hole 4 is arranged above the lower eddy current displacement sensor 3, the connection support plate 5 is installed above the mechanical joint placement hole 4, and the connection support plate 5 is installed above the connection support plate 5. A joint distance detector 6, the support backboard 7 is installed above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com