Production method of ceramic tile and ceramic tile

A manufacturing method and technology of ceramic tiles, applied in the field of ceramic manufacturing, can solve the problems of inability to form natural rock textures or patterns, single color, poor decoration, etc., and achieve the effect of improving wear resistance, surface hardness and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepared zirconium-based opaque glaze: 85% glaze powder, 10% zirconium silicate, 5% kaolin.

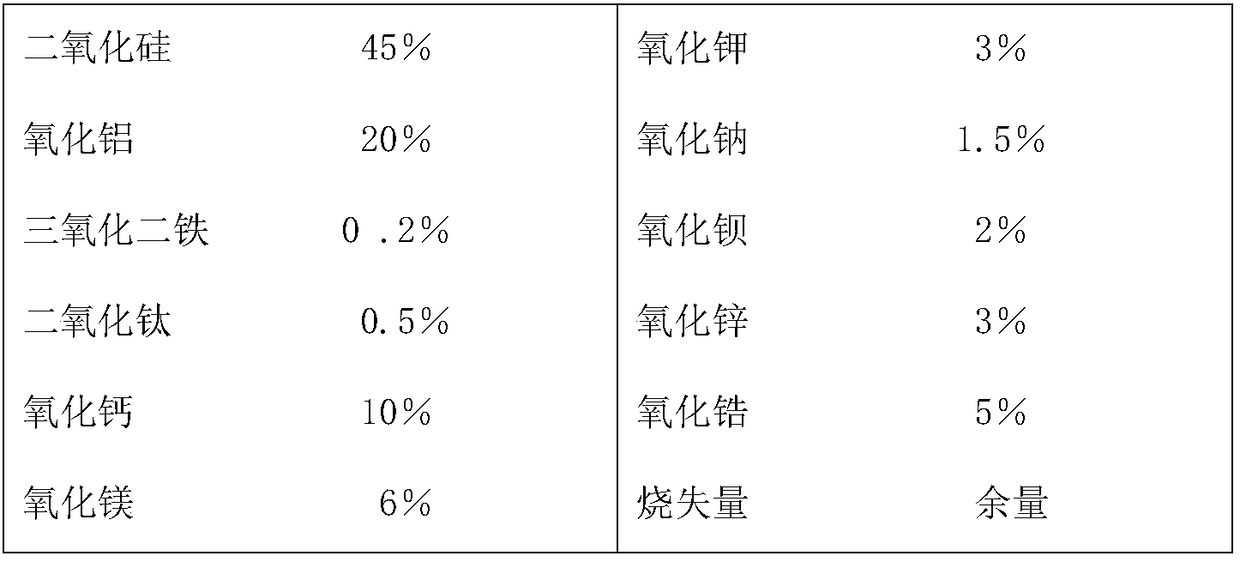

[0036] Wherein the glaze powder ingredient list is:

[0037]

[0038] The ceramic brick produced by the method of the present invention has the following advantages:

[0039] Strong wear resistance, high surface hardness, good anti-slip performance, the overall effect of the tiles is natural and real, and the three-dimensional sense of layers and protrusions is strong. It will become a new generation of best-selling products in the international market after changing the disadvantages of excessive material consumption and energy consumption of polished tiles, and the production environment is easy to cause pollution.

[0040] Preferably, the inkjet printing pixel in step B is set to be greater than or equal to 360DPI.

[0041] Preferably, in step C, the thickness of the transparent protective glaze is 0.01-0.05mm.

[0042] The printed decorative layer of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com