Combined set cylinder insulating device for sweet potato starch production

The technology of sweet potato starch and heat preservation device is applied in the field of combined cylinder heat preservation device for sweet potato starch production, which can solve the problems of unfavorable daily production and development of enterprises, waste of labor cost and time cost, unguaranteed temperature, etc. Time cost and labor cost, strong practicability, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

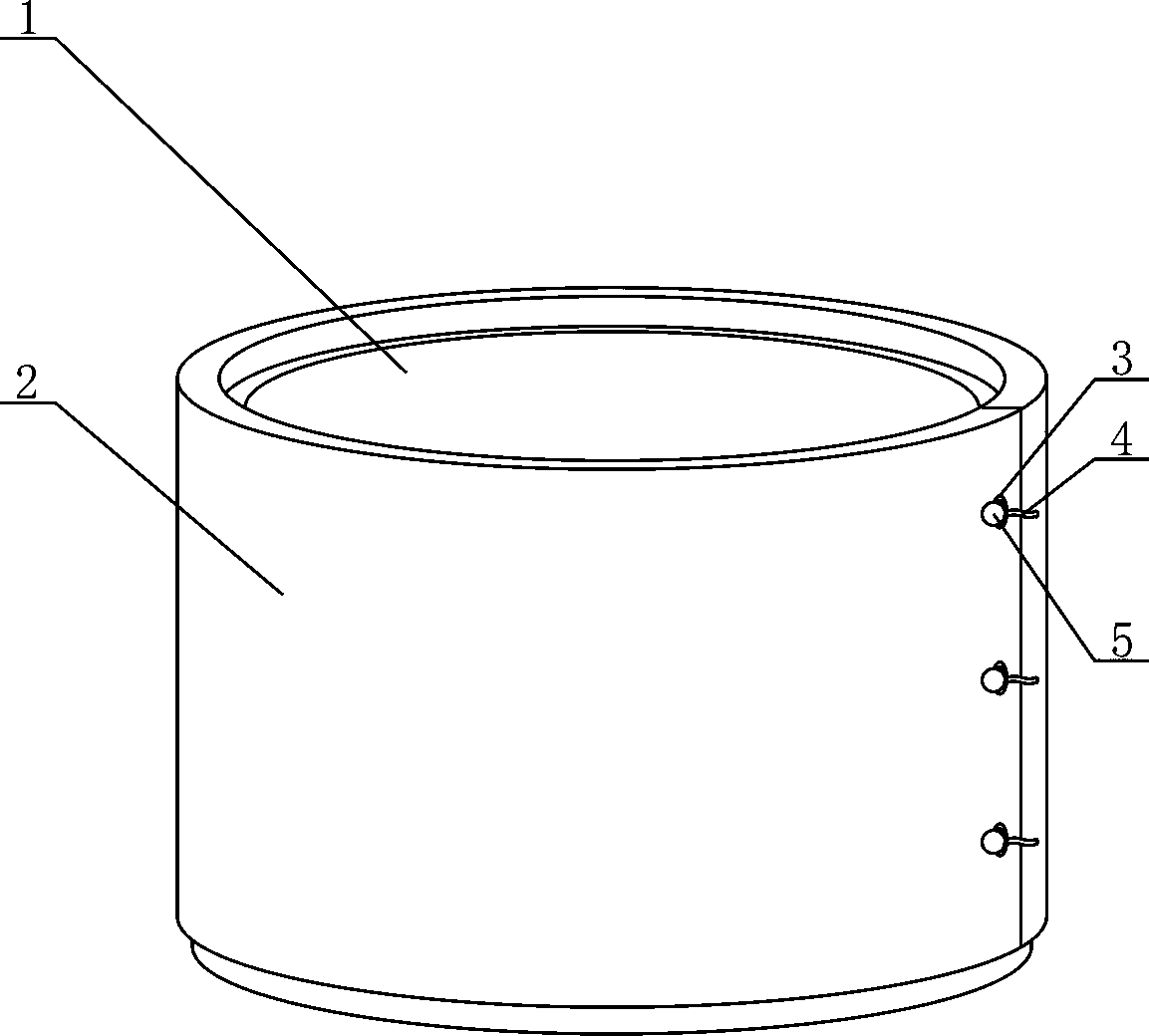

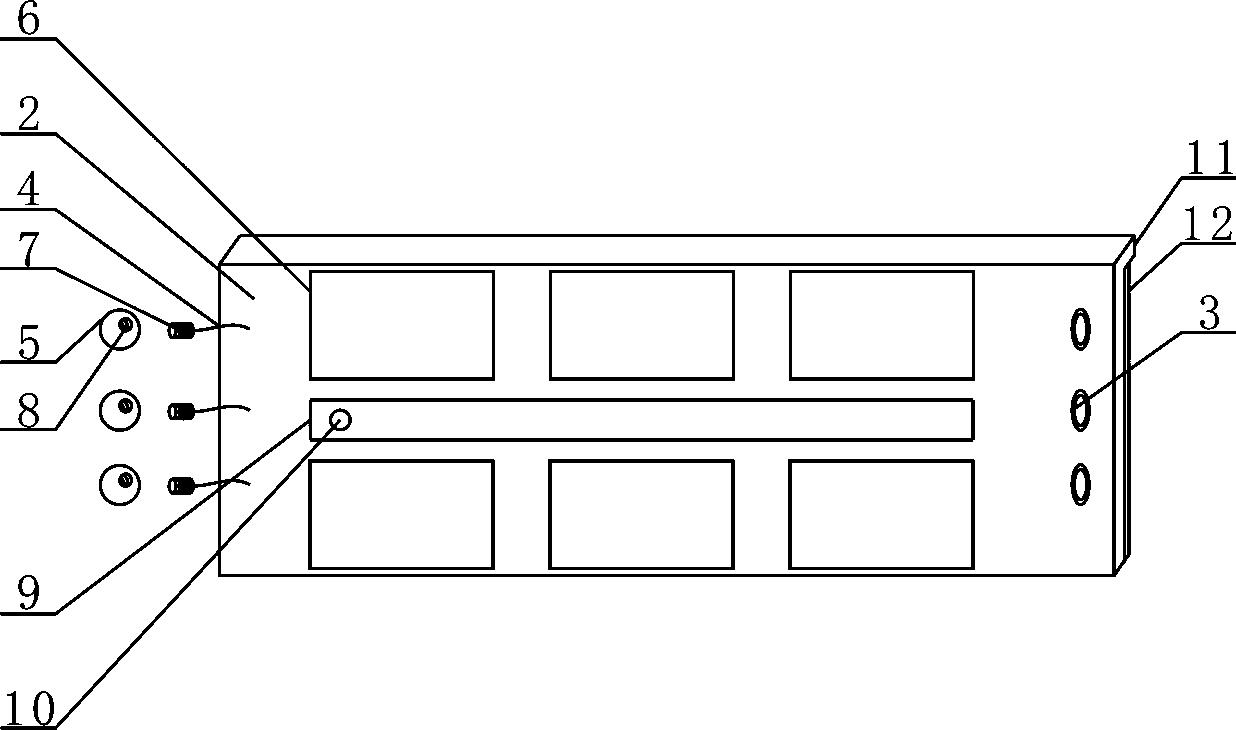

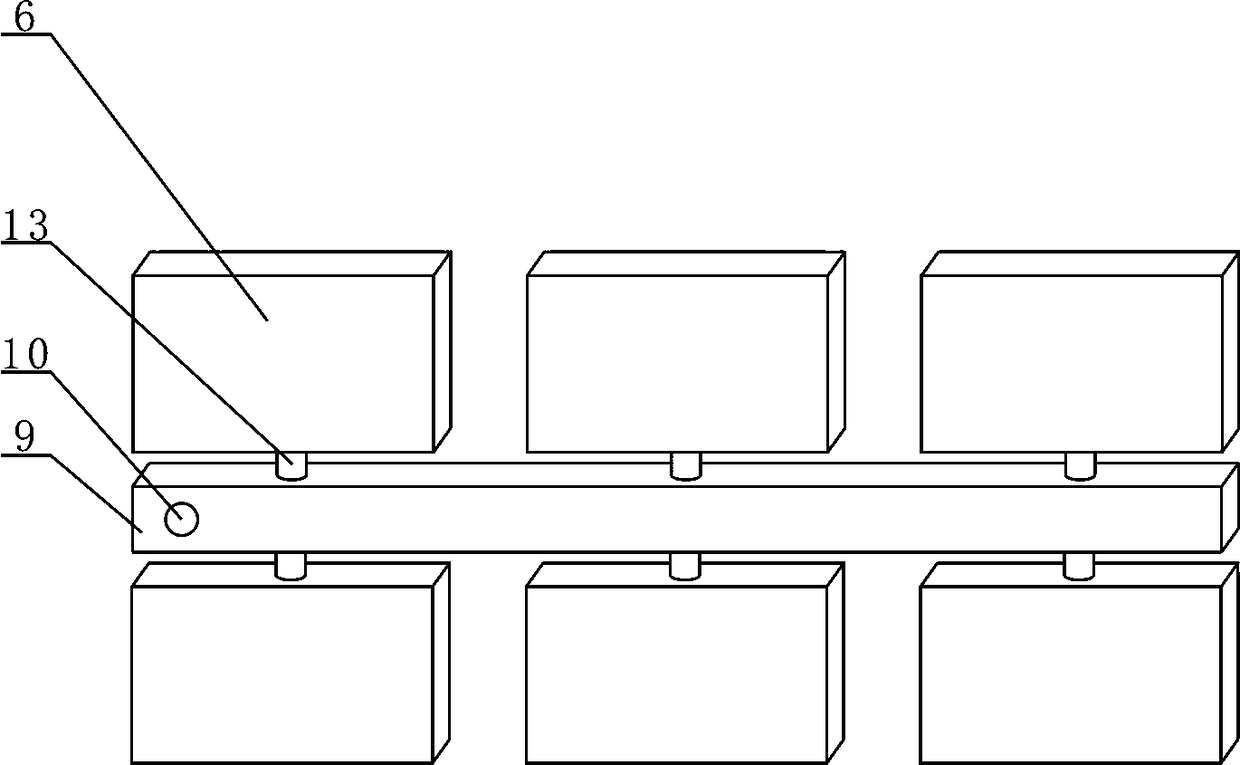

[0033] In Example 1, the combined type sitting-tank heat preservation device for the production of sweet potato starch. When in use, a water injection pipe 9 is set in the connecting plate 2, and then a water inlet and a water injection pipe are set on the connecting plate 2. A water injection hole 10 is set on 9 and the plug plugs the water inlet and water injection hole 10 on the connecting plate 2, and then a water distribution pipe 13 is installed on the water injection pipe 9, and a water storage box 6 is installed on the water distribution pipe 13, and then connected A fixing plate 11 is set on the upper end of one end of the plate 2, and then a fixing ring 3 and a connecting rope 4 are set on the other end of the connecting plate 2, and then the end of the connecting plate 2 with the fixing plate 11 is set with heat preservation Plate 12, set the fluff 14 on the heat preservation plate 12, then set the connecting block 7 on the connecting rope 4, then set the thread on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com