Overall hoisted prefabricated underground continuous wall structure and prefabricating and construction method thereof

An underground diaphragm wall and hoisting technology, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of reducing the waterproof function of underground diaphragm walls, easy cracking and damage at joints, and small roots of mortise joints. Achieve the effects of shortening the construction period, facilitating subsequent processing, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

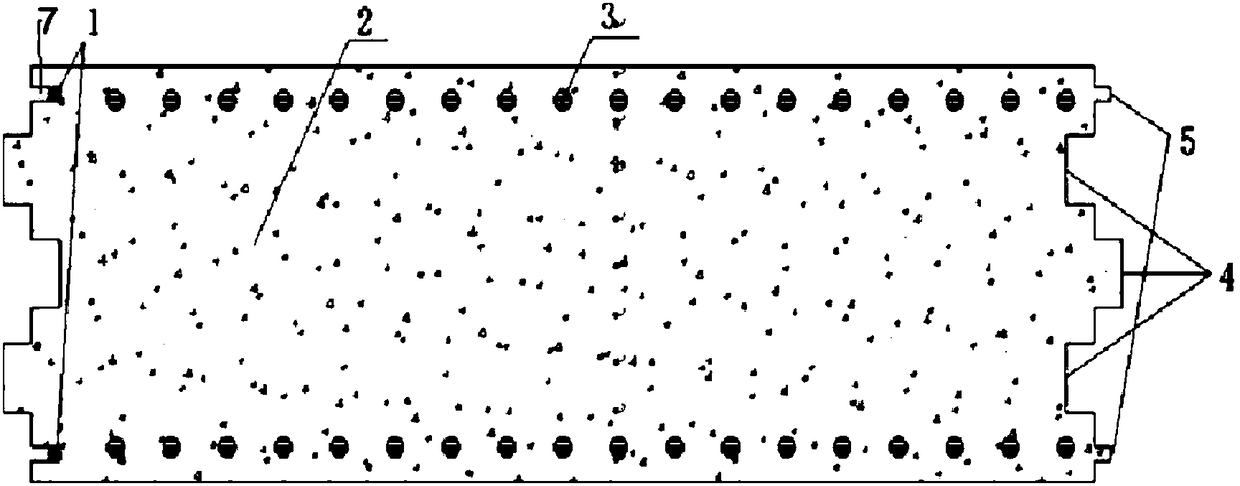

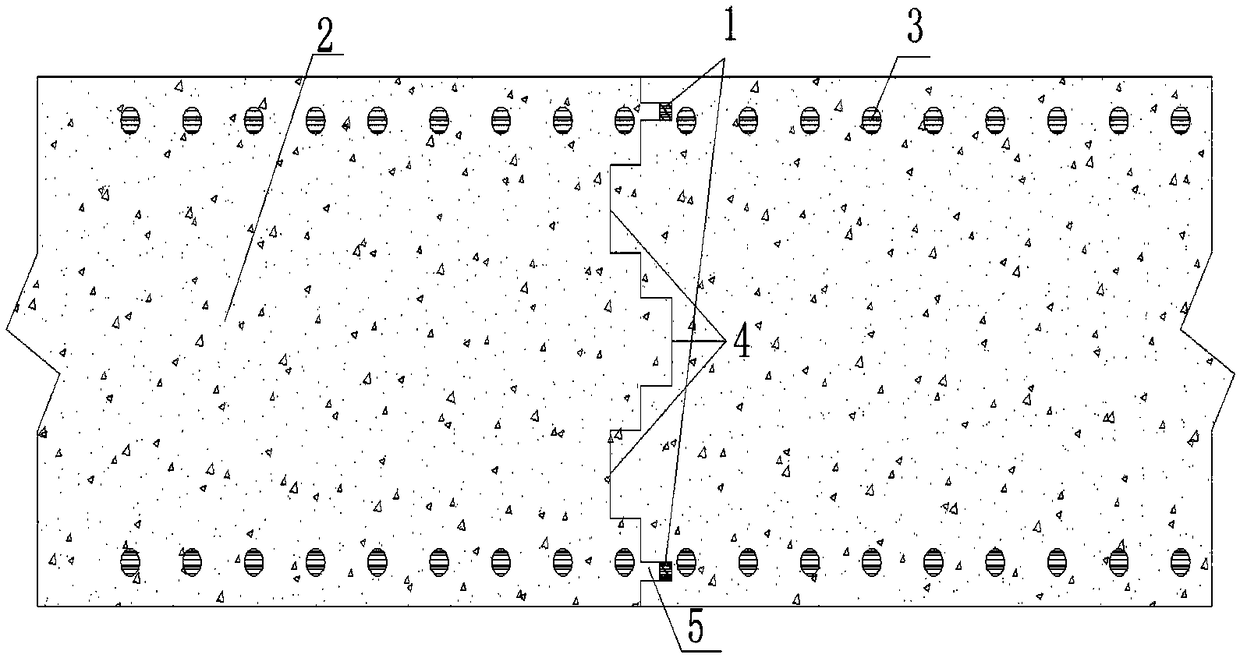

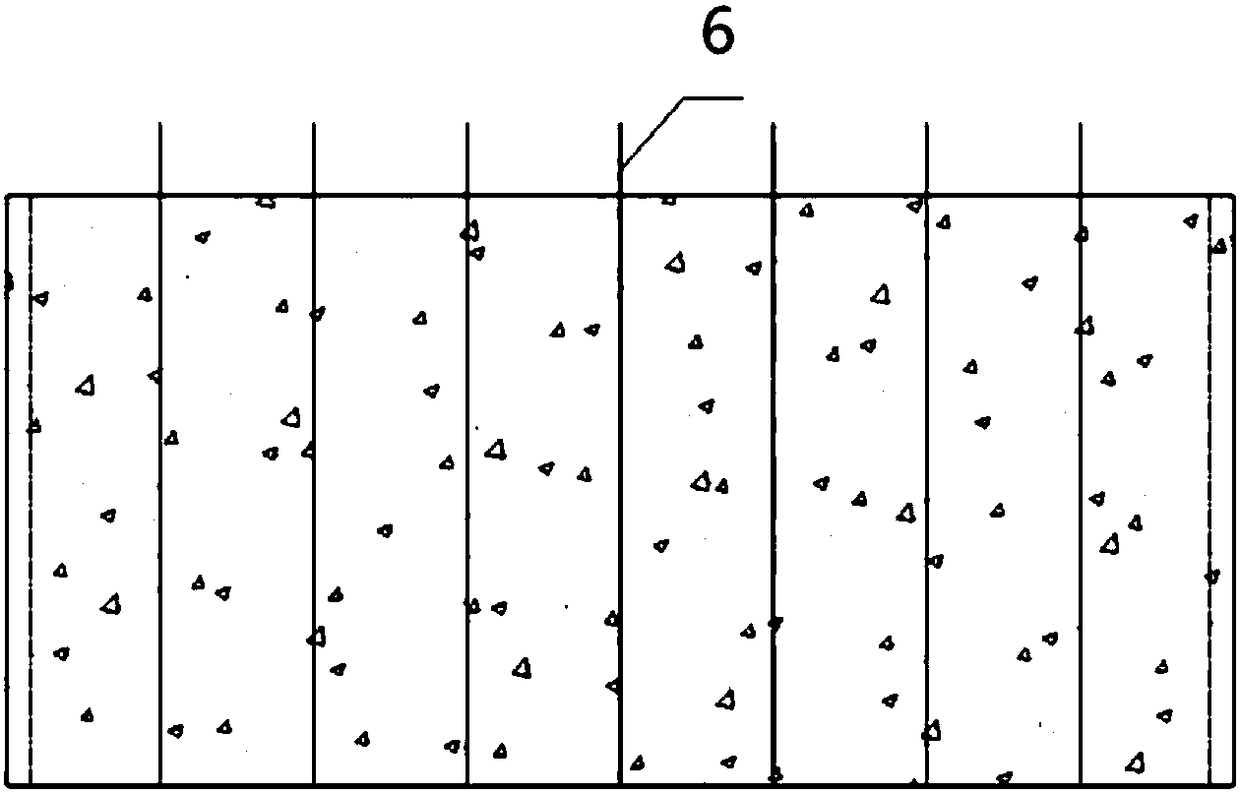

[0031] like figure 1 As shown, it is a structural schematic diagram of an integral hoisting prefabricated underground diaphragm wall body provided by the present invention. It includes a prefabricated underground diaphragm wall body 2, the two ends of the prefabricated underground diaphragm wall body 2 are correspondingly provided with mortise joints 4, and the two sides of the wall body at the butt joint of the prefabricated underground diaphragm wall are respectively provided with water stop grooves 7. The water-swellable rubber water-stop strip 1 is provided in the water-stop groove 7 . The water-swellable rubber water-stop strip 1 can swell three times in volume after being exposed to water, and can fully fill the gap of the water-stop joint 5, and has an excellent waterproof effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com