Deep learning recognition method for ferrite defects based on Fisher criterion

A technology of learning recognition and defect depth, which is applied in the field of surface defect recognition of rectangular ferrite magnetic sheets, can solve the problems of low efficiency and high error rate, and achieve the effect of strengthening detection speed, high accuracy and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

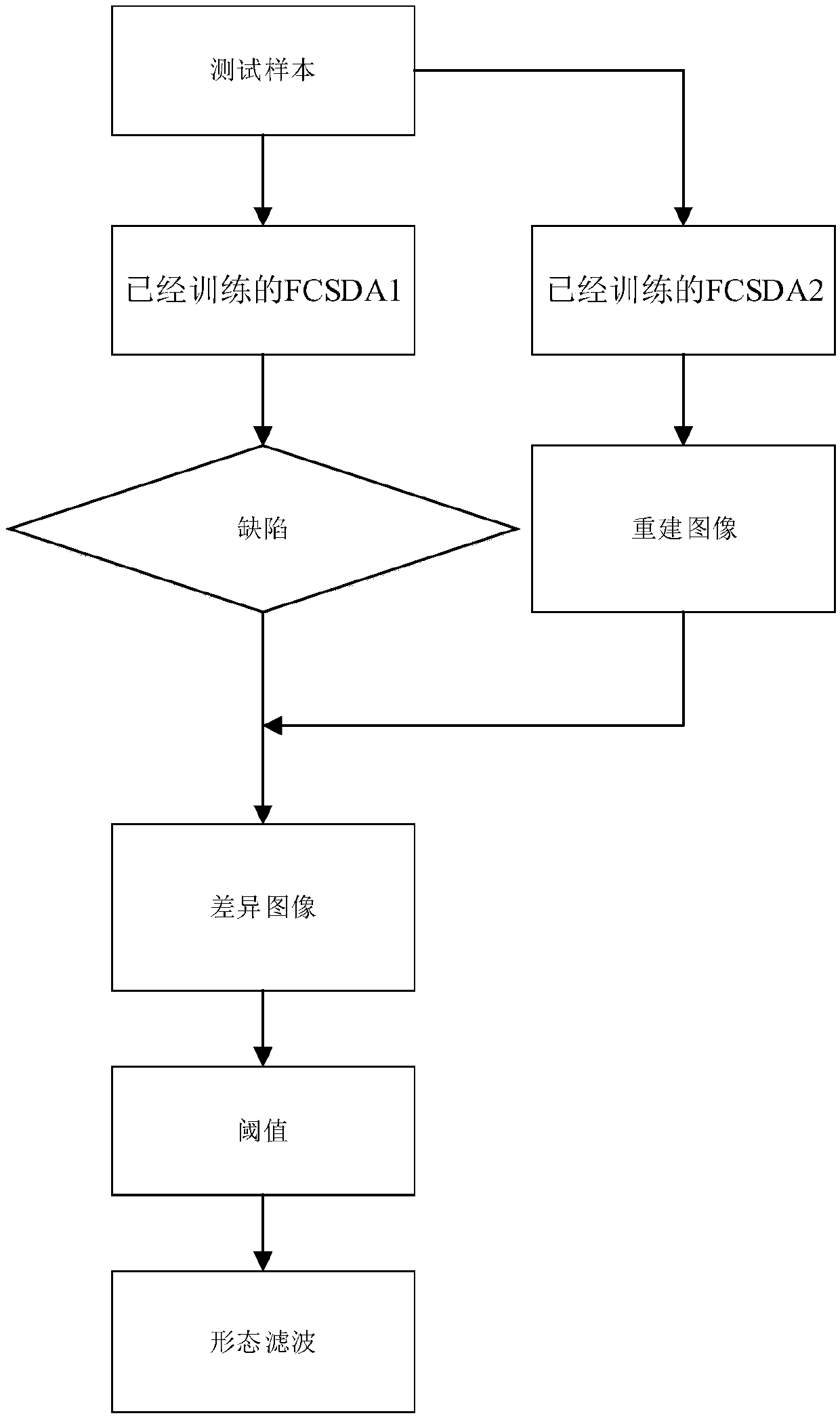

[0058] A deep learning recognition method for ferrite defects based on Fisher's criterion includes the following steps:

[0059] Step 1: Obtain images of rectangular ferrite magnetic sheets of known defects and defect-free samples through an industrial camera;

[0060] Step 2: Obtain images of defective and non-defective ferrite samples;

[0061] Step 3: Define the noise reduction and denoising autoencoder SDA;

[0062] The specific processing method is as follows:

[0063] (1) Define the vectors z and y respectively, and the calculation formula is as follows:

[0064] z=s(Wx+b)

[0065] y=g θ '(z)=s(W'z+b)

[0066] Among them, W is the weight matrix, b is the input bias, s() is the sigmoid function, z is a d'-dimensional vector, x is a d-dimensional input vector, y is also a d-dimensional vector as an approximate vector of x, and the x and y vector elements are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com