Bearing polishing process

A process and bearing technology, applied in grinding machines, machine tools suitable for grinding workpiece edges, manufacturing tools, etc., can solve problems such as increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

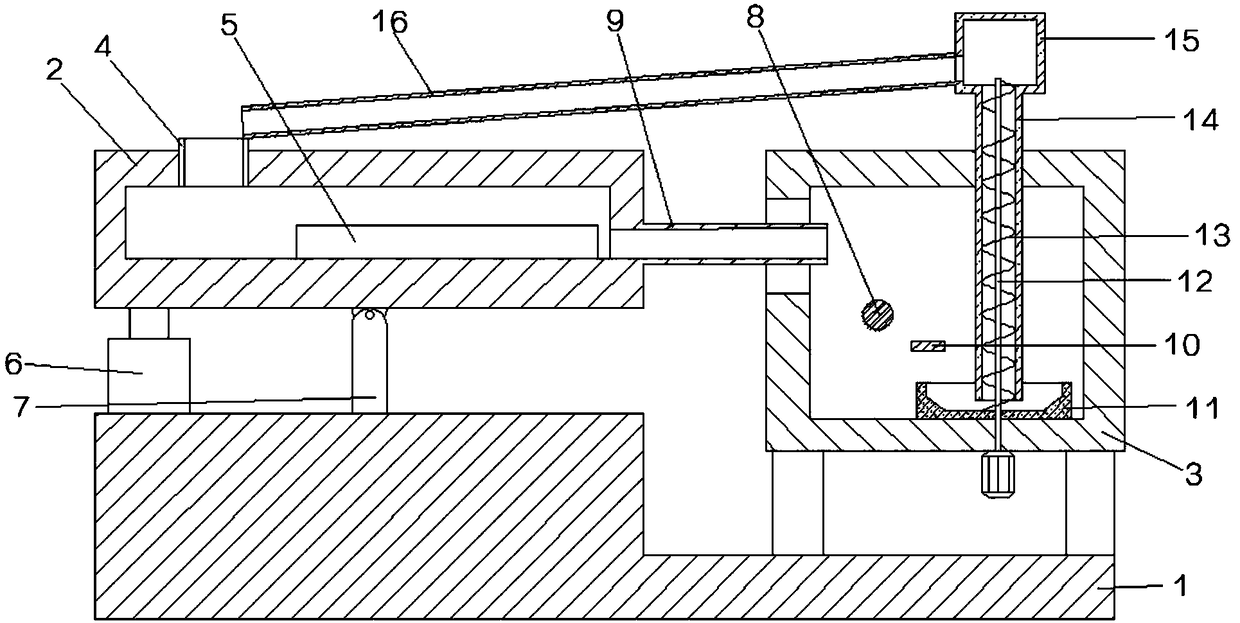

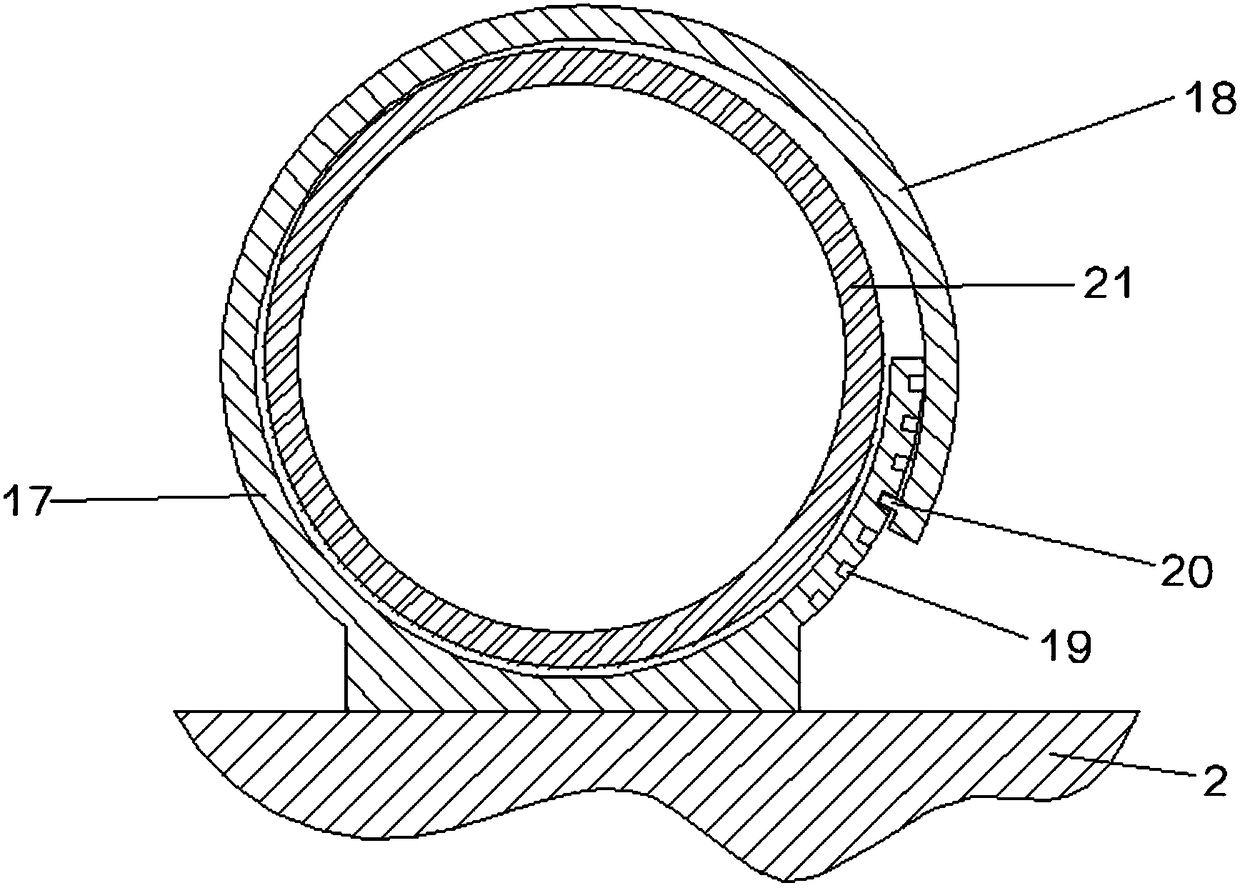

[0025] The reference signs in the drawings of the description include: frame 1, inner circle grinding box 2, outer circle grinding box 3, material inlet 4, positioning mechanism 5, hydraulic cylinder 6, pillar 7, rotating shaft 8, feeding channel 9, Electromagnet 10, collection tank 11, drive shaft 12, spiral blade 13, conveying channel 14, transfer box 15, feeding channel 16, first rubber anti-slip sheet 17, second rubber anti-slip sheet 18, card slot 19, hook 20, bearing Ferrule 21.

[0026] The embodiment is basically as figure 1 and figure 2 As shown: the grinding device includes a frame 1 with high left and low right, an inner grinding box 2 is installed on the higher end surface on the left side of the frame 1, and an outer grinding box is fixedly installed on the lower end surface on the right side of the frame 1 3.

[0027] The inner bottom surface of the inner circle gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com