Scissors for automatic shearing device

A shearing device and scissors technology, applied in metal processing and other directions, can solve the problems of high shearing frequency, large shearing force, and scissors can not meet the requirements, etc., and achieve the effect of reliable and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

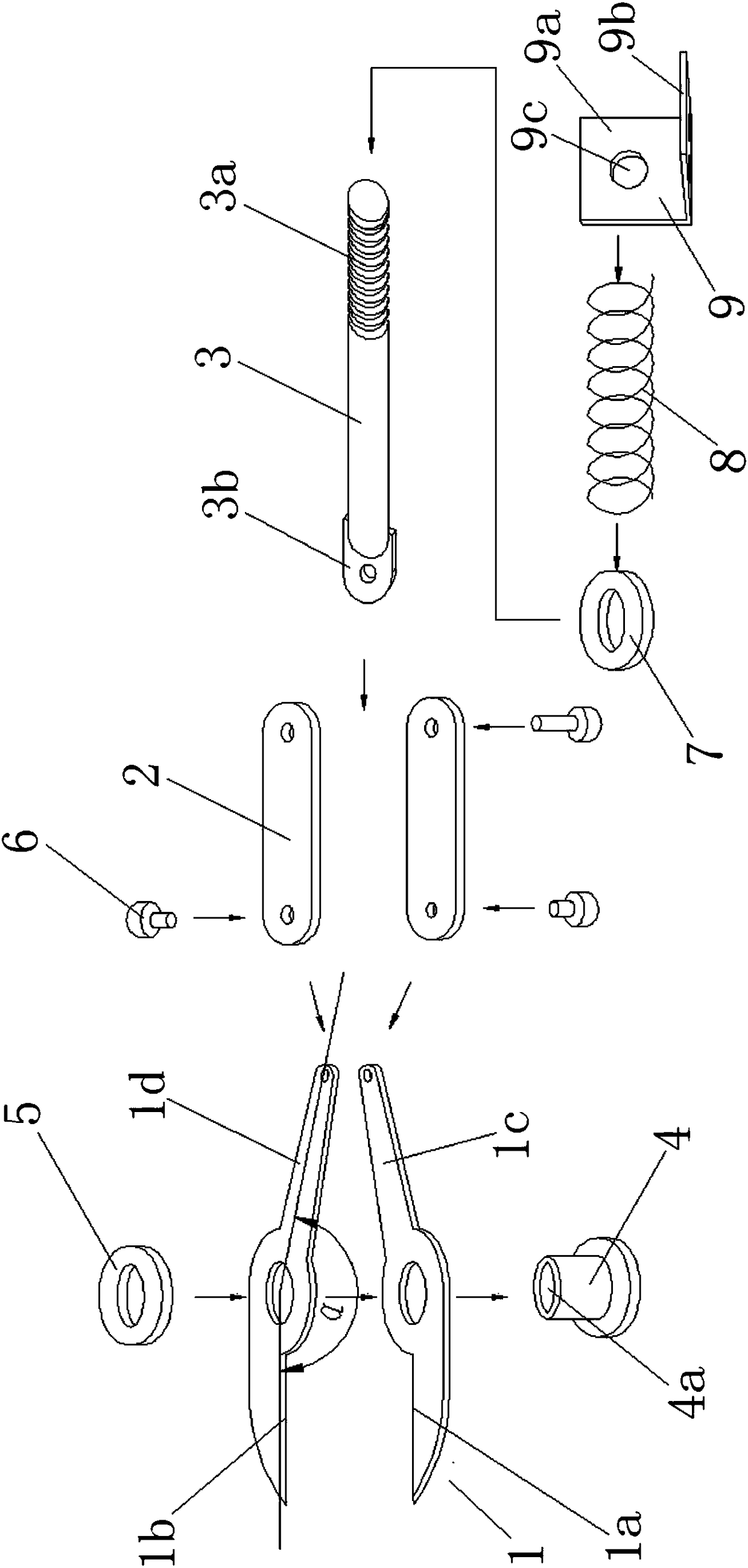

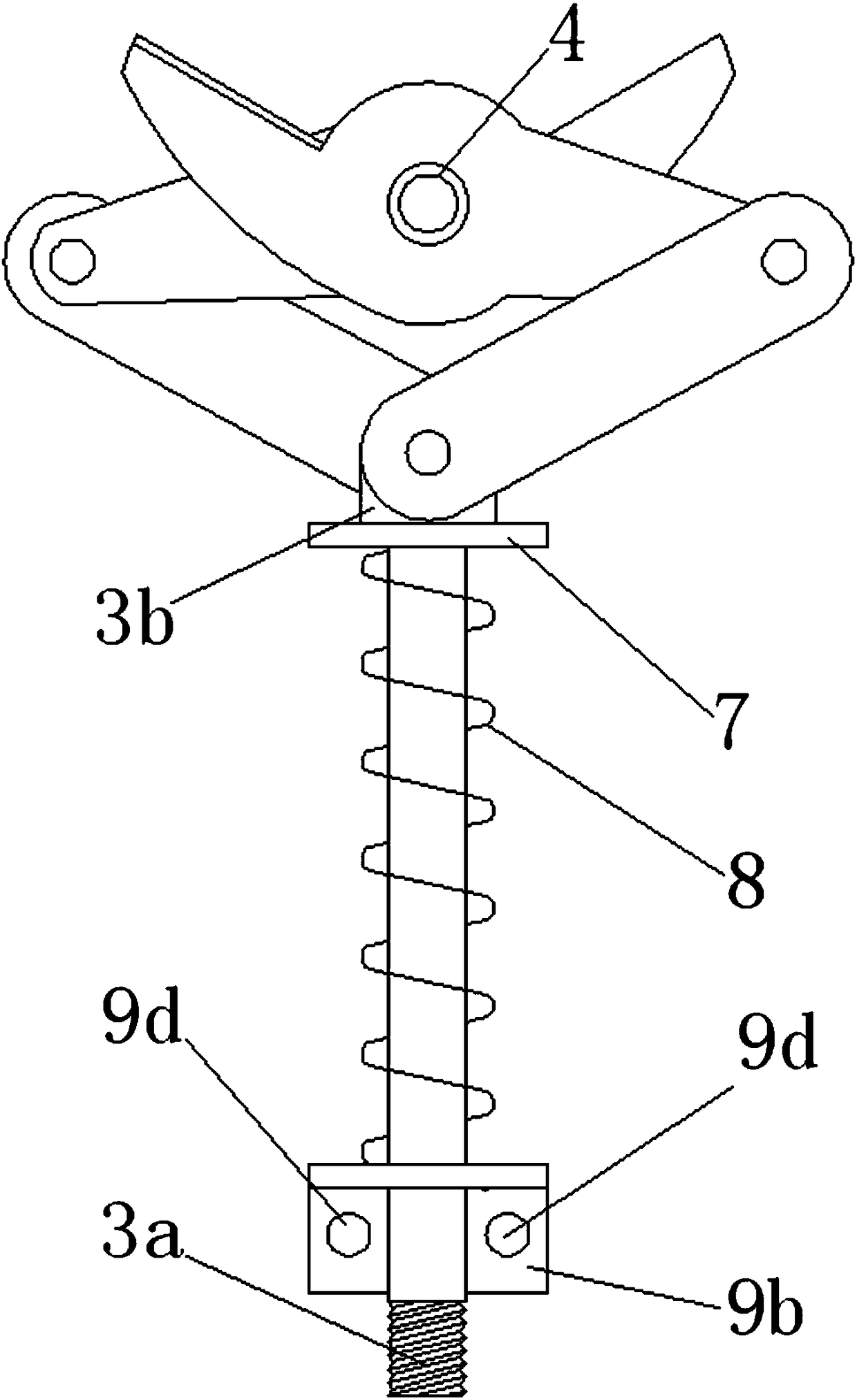

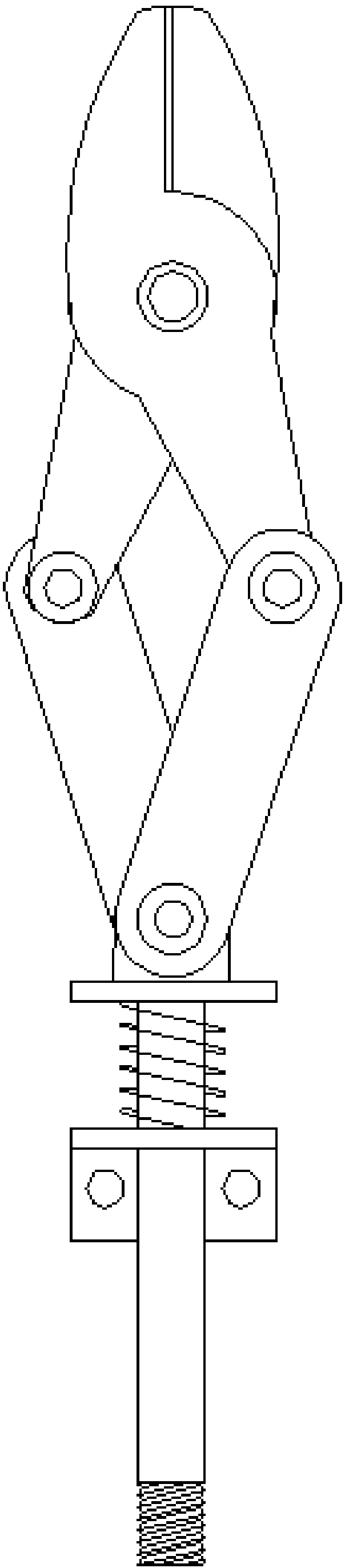

[0031] In order to achieve the purpose of the present invention, a kind of scissors that is used for automatic cutting device, comprises: scissors 1, possesses the first blade portion 1a, the second blade portion 1b that open and close alternately, the first blade portion 1a is connected with the first knife handle 1c , the second blade 1b is connected to the second handle 1d, and is hinged at the connection between the first blade 1a and the first handle 1c and the connection between the second blade 1b and the second handle 1d. Also hinged. Connecting rods 2, one end of the two connecting rods 2 are hinged to each other and the tails of the first knife handle 1c and the second knife handle 1d are respectively hinged, and the two connecting rods 2 form four links with the first knife handle 1c and the second knife handle 1d. Rod mechanism; the push-pull ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com