Hot-press sealing paper bag producing machine

A bag making machine and paper bag technology, applied in bag making operations, container manufacturing machinery, paper making, etc., can solve the problem of slippage of the cutting knife and the feeding paper bag, and achieve the goal of ensuring cutting quality, reducing vibration and reducing noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

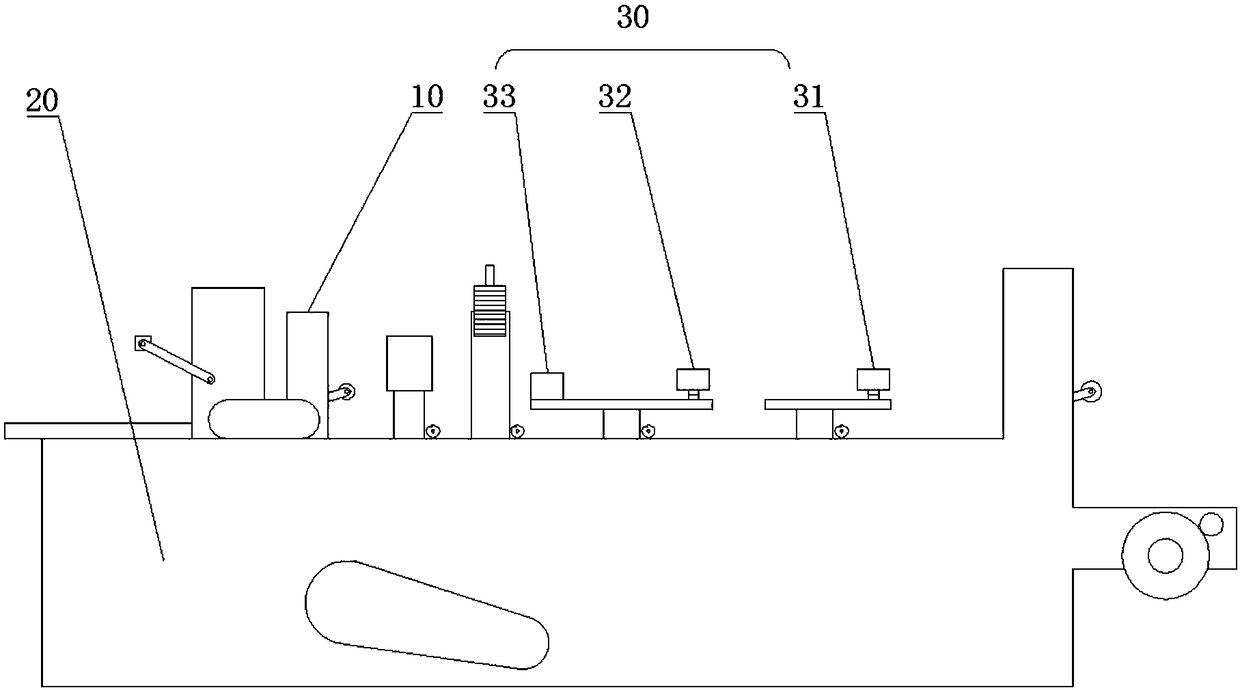

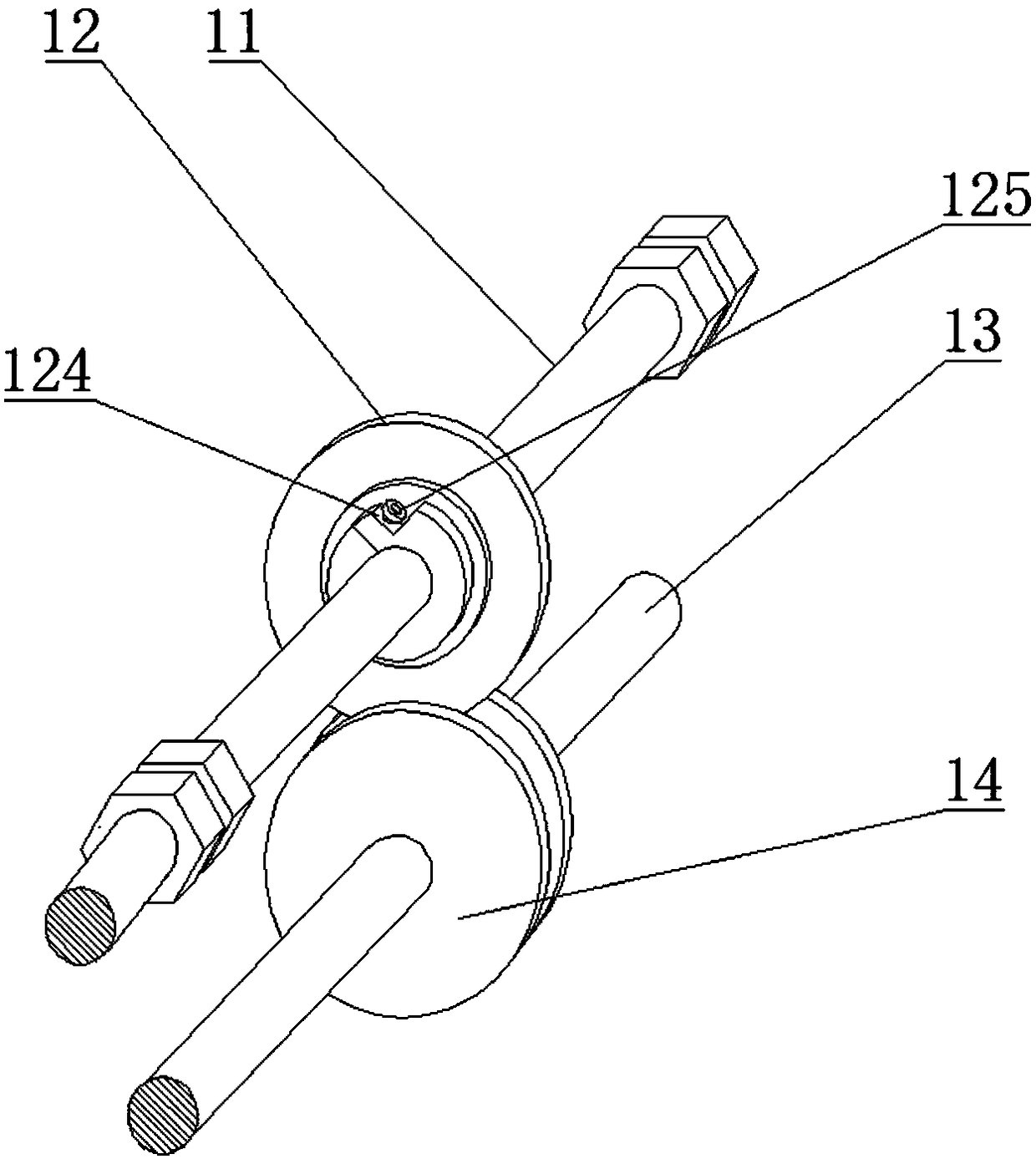

[0047] A hot-press sealing paper bag making machine, comprising a frame 20, a cutting device 10 is arranged on the frame 20, the cutting device includes an upper cutter bar 11, a circular cutter 12 is arranged on the upper cutter bar, and a main shaft is also included 13. The main shaft 13 is located below the upper knife bar 11. The main shaft 13 is provided with a lower knife groove 14. The lower knife groove 14 is set correspondingly to the circular cutter 12. The blade 121 of the circular cutter 12 is connected to the notch of the lower knife groove 14. One side wall or two side walls are in contact.

[0048] In the present embodiment, the circular cutter 12 is arranged on the upper knife bar 11, and the main shaft 13 is arranged below the upper knife bar 11, and the lower knife groove 14 corresponding to the circular cutter 12 is arranged on the said main shaft 13, and the circular cutter 12 The blade 121 is in contact with one side wall or both side walls of the notch of...

Embodiment 2

[0050] On the basis of Embodiment 1, the upper cutter bar 11 is fixed on the frame 20, and the circular cutter 12 is sleeved on the upper cutter bar 11 through a bearing.

[0051] In the present embodiment, the upper cutter bar 11 is fixed on the frame 20 of the bag making machine, and the circular cutter 12 is sleeved on the upper cutter bar 11 by a bearing. Therefore, in the course of work, only the circular cutter 12 rotates under the frictional force of the lower knife groove 14, while the upper knife bar 11 is fixed. By changing the traditional way that the upper knife rod is set on the frame through bearings, it avoids the need to set the gear on the upper knife rod to mesh with the chassis in the traditional way, or the situation that the upper knife rod rotates around its own axis, and reduces the burden on the upper knife. The vibration between the rod and the frame greatly reduces the noise during production.

Embodiment 3

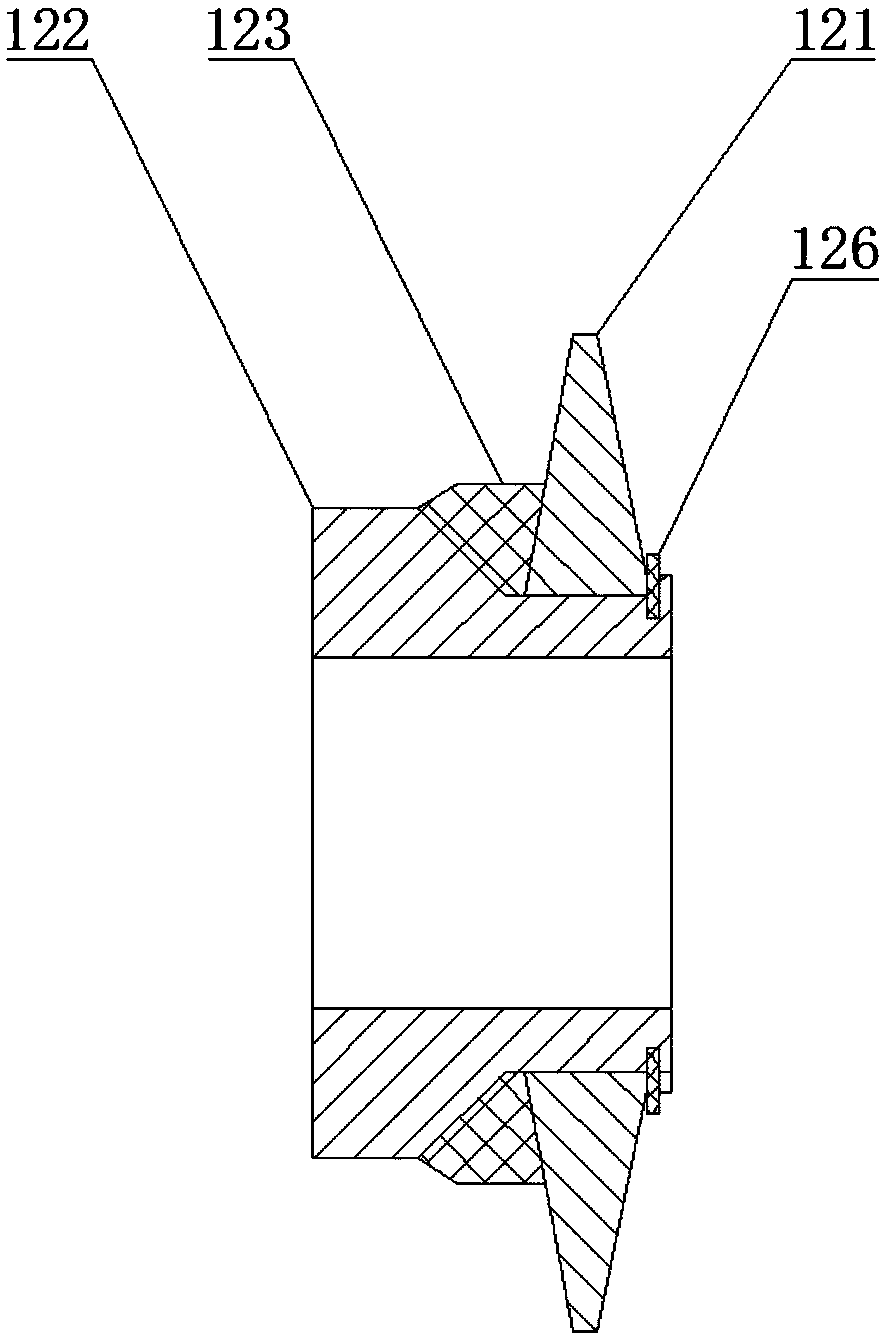

[0053] On the basis of Embodiment 2, the circular cutter 12 includes a cutter seat 122, and a blade groove is arranged on the cutter seat 122, and the blade 121 is sleeved on the blade groove, and between the left end surface of the blade 121 and the side wall of the blade groove An elastic element 123 is provided, and the left end surface of the blade 121 and the side wall of the blade slot are in contact with the elastic element 123 .

[0054] In this embodiment, the circular cutter 12 includes a cutter seat 122, a blade groove is arranged on the cutter seat 122, the blade 121 is sleeved on the blade groove, and elastic The element 123 , and the left end surface of the blade 121 , and the side wall of the blade slot are all in contact with the elastic element 123 . The blade 121 is rotated by the lower slit 14 through frictional force. During the production process, the blade 121 will follow the feeding of the paper bag to keep a slight floating left and right, so as to avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com