Walking wheel structure for narrow-width micro-cultivator

A technology of micro-tiller and walking wheel, which is applied in the directions of wheels, rims, transportation and packaging, can solve the problems of limiting the utilization rate of micro-tiller on sloping land, complex processing technology of walking wheels, and poor gripping effect of walking wheels, etc. To achieve the effect of reducing adverse effects, unaffected stability, and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

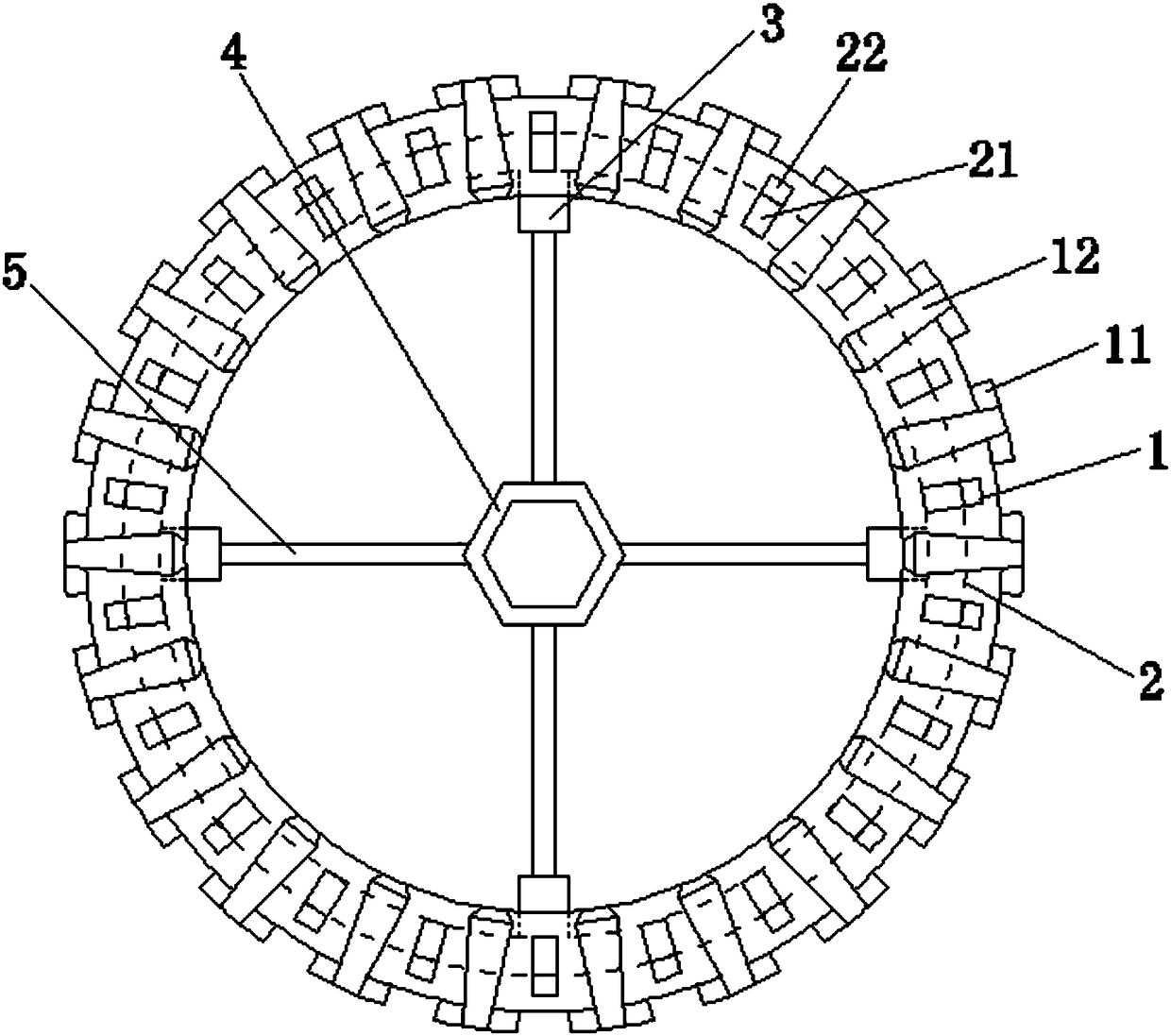

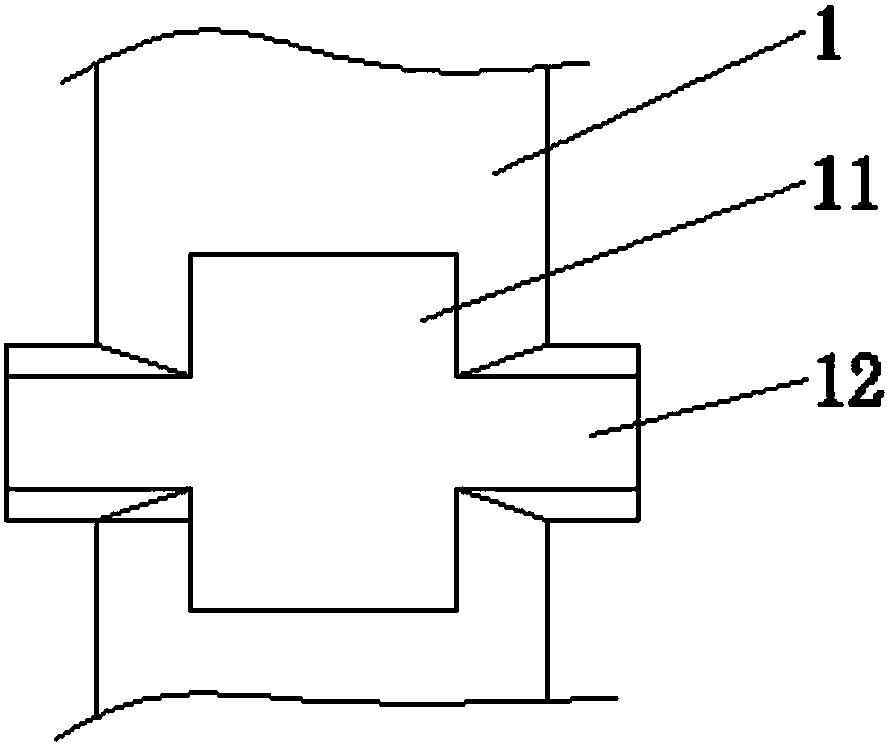

[0022] Such as figure 1 , figure 2 As shown, the road wheel rim of the tiller has a rim 1 made of rubber. The width of the rim 1 is 50-70 mm, and the specific width of the rim 1 is determined according to actual needs, and in this embodiment, it is preferably 60 mm. Radial bosses 11 are evenly distributed on the outer circumference of the rim 1, and the radial bosses 11 and the rim 1 are integrally structured. The number of the rims 1 is determined according to actual needs, as long as the gap between two adjacent radial bosses 11 The distance between radial bosses 11 along the circumferential direction can be less than the length. The outer end surface of the radial boss 11 is an arc surface, and knurls are arranged on the outer end surface of the radial boss 11. The shapes of the knurling can be various, and the center of the circle where the outer end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com