Intelligent packaging line for PCB finished product and packaging process of intelligent packaging line

A packaging line and PCB board technology, which is applied in the field of PCB finished product intelligent packaging line and its packaging process, can solve the problems of no barcode scanning recognition function, PCB board model mismatch, affecting enterprise business, etc., to solve the problem of frequent manual feeding, Avoid manual missed picking and the effect of avoiding the number of boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

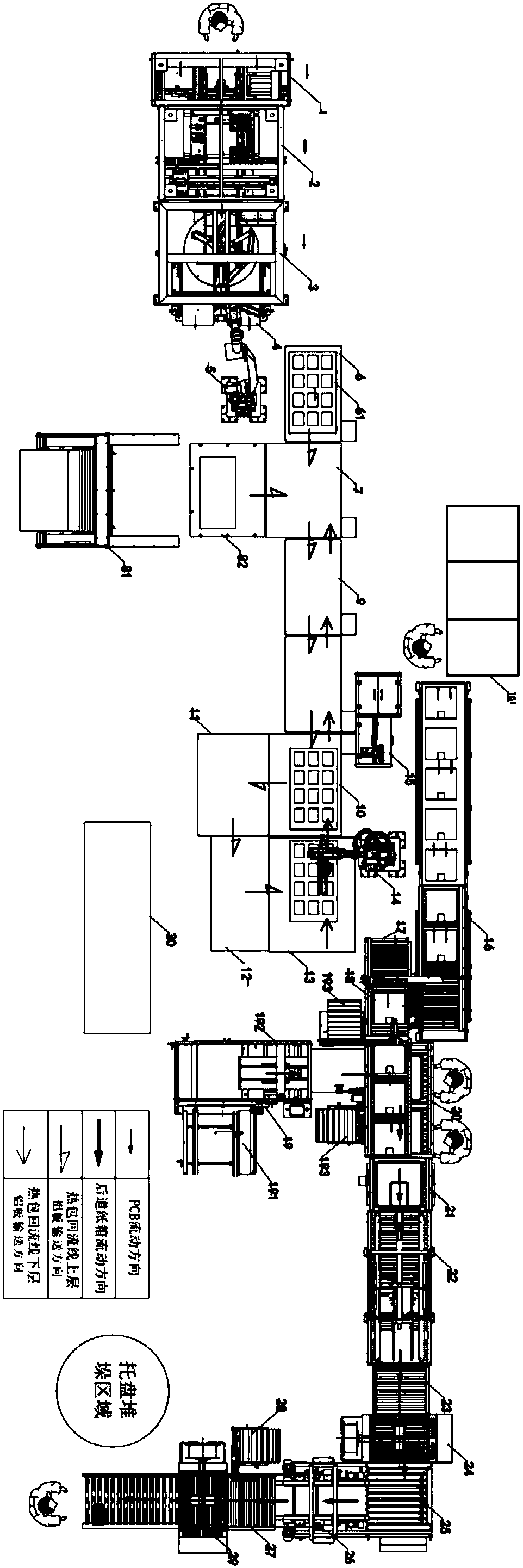

[0062] Such as figure 1 As shown, it is a schematic top view structure diagram of the preferred intelligent packaging line for PCB finished products of the present invention.

[0063] Such as figure 1 As shown, an intelligent packaging line for PCB finished products includes a PCB board feeding line, a bubble film feeding line, a hot pack reflow line, a hot and cold double-layer reflow line 16, a carton packaging line and an intelligent control center 30;

[0064] The intelligent control center 30, using three-level network control, can realize the internal and external interconnection and information interconnection of the PCB board feeding line, bubble film feeding line, hot pack return line, cold and hot double-layer return line 16, and carton packaging line. Human-computer interaction, machine-machine interaction, and machine-material int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com