Construction method for super-large-span tunnel on basis of benching tunneling CD method

A construction method and step technology, which can be used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of instability, collapse, and self-stabilization of the excavation face.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

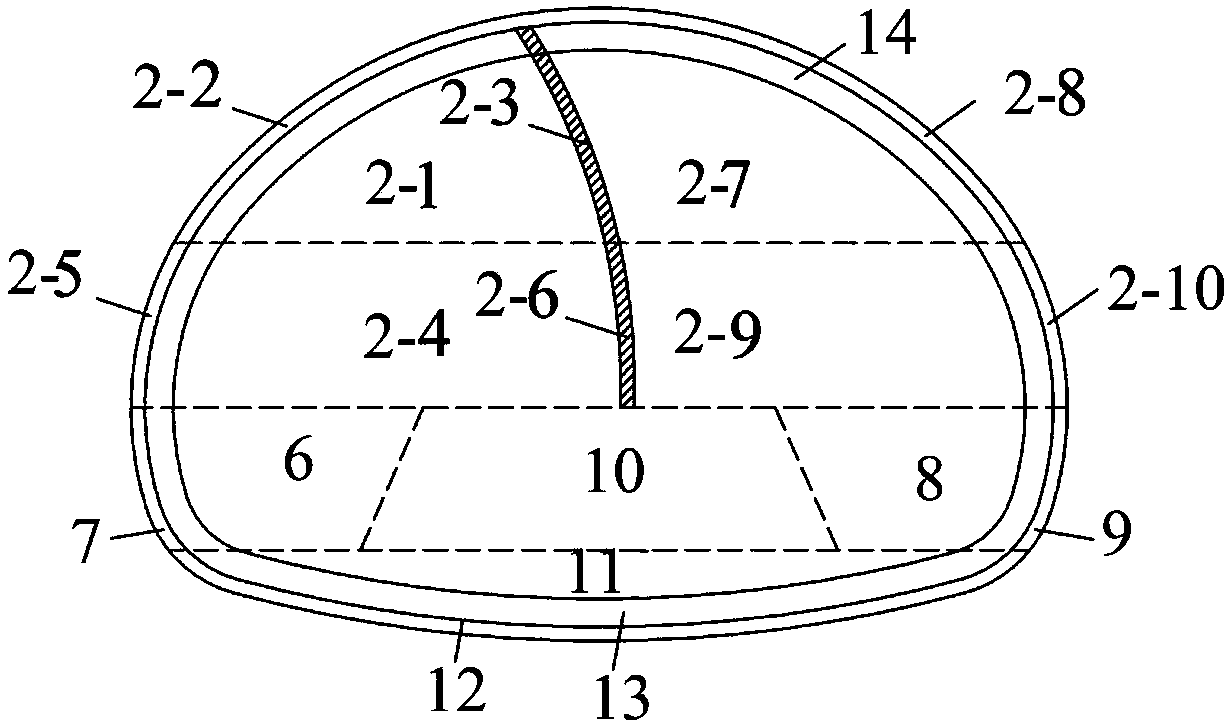

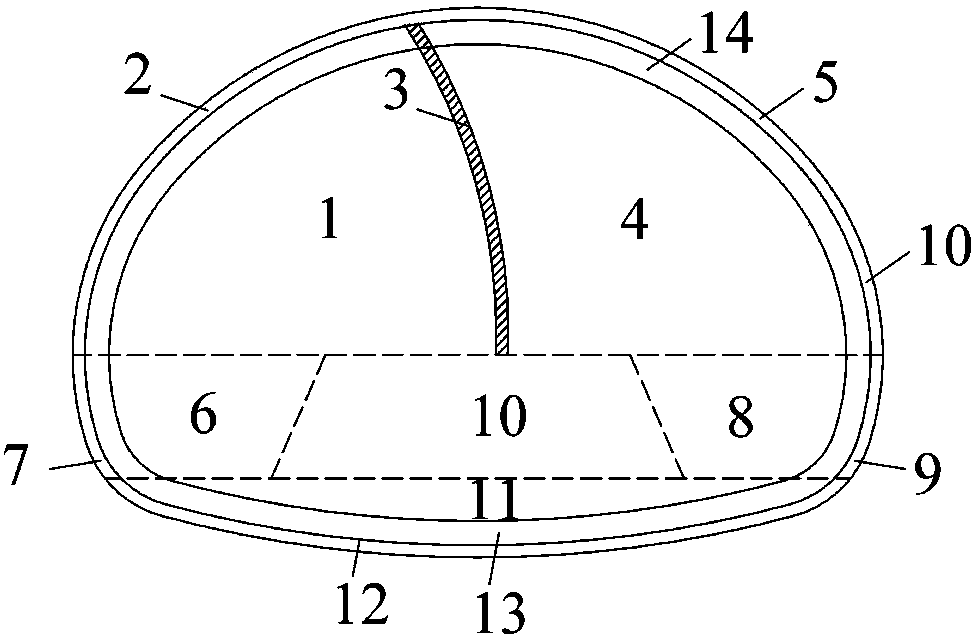

[0036] This embodiment provides a construction method of the step-up CD method for super-long-span tunnels. In view of the poor stability of the surrounding rock of super-long-span tunnels, by increasing the number of steps of the leading pilot pit and the trailing pilot pit in the step-up CD method, the traditional The step-up CD method was improved to avoid problems such as face instability and collapse caused by the high excavation height of the first pilot pit and the latter pilot pit. The schematic diagram of the step-up CD method after improvement is as follows: figure 1 shown. The specific process after the improvement of the construction method is as follows:

[0037] ①Excavation of the upper step 2-1 of the leading pilot pit: the height of the upper step of the leading pilot pit is 3-5m, and the length of the step is 5-10m;

[0038] ②The initial support of the upper step of the pilot pit is 2-2, and the temporary support of the middle wall of the upper step of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com