Tunnel drainage device and tunnel monolithic track bed

A tunnel drainage and integral ballast bed technology, applied in drainage, safety devices, roads, etc., can solve problems affecting the normal operation of the tunnel and tunnel safety, and achieve the effect of strengthening and ensuring the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

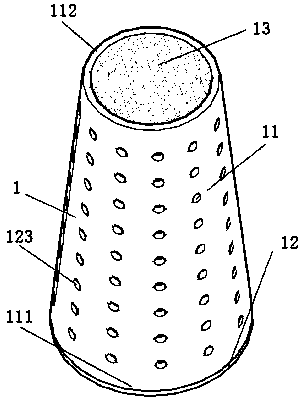

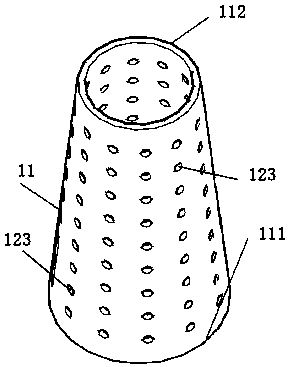

[0063] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the tunnel drainage device 1 includes a drainage cylinder main body 11 for pre-embedding in the integral ballast bed 2 of the tunnel. The drainage cylinder main body 11 is a cylindrical structure. The embedded end 111 inside, and the drainage end 112 extending out of the integral ballast bed 2 of the tunnel, the embedded end 111 communicates with the drainage end 112.

[0064] Through the tunnel drainage device 1 of this solution, the tunnel drainage device 1 is pre-embedded in the integral ballast bed 2 of the tunnel, the seepage water at the bottom of the tunnel penetrates into the main body 11 of the drainage tube, and the cavity space in the main body 11 of the drainage tube is used to collect and store seepage water , the embedded end 111 communicates with the drainage end 112, the seepage water flows to the drainage end 112 through the embedded end 111, and the seepage water is discharged...

Embodiment 2

[0076] like Figure 4 and Figure 5 As shown in the tunnel integral ballast bed 2, the tunnel drainage device 1 as described above is pre-embedded in the tunnel integral ballast bed 2, and the tunnel drainage device 1 is buried in the tunnel integral ballast bed 2 before pouring the ballast bed concrete, effectively avoiding stress The steel bar does not affect the overall mechanical performance of the ballast bed, ensures the structural strength of the overall ballast bed 2 of the tunnel, and can effectively discharge water seepage in the ballast bed, ensuring the safety of the ballast bed and the tunnel.

[0077] Further, the tunnel drainage device 1 is arranged on the centerline of the integral ballast bed 2 of the tunnel.

[0078] As one of the implementations, the tunnel drainage devices 1 are arranged sequentially along the length direction of the tunnel, the distance between two adjacent tunnel drainage devices 1 is 3-6m, and the overall track bed 2 of the tunnel is pr...

Embodiment 3

[0083] The construction method of the tunnel drainage device, when the tunnel drainage device as in embodiment 1 is used to discharge the water seepage process of the integral ballast bed of the tunnel, proceed according to the following construction steps:

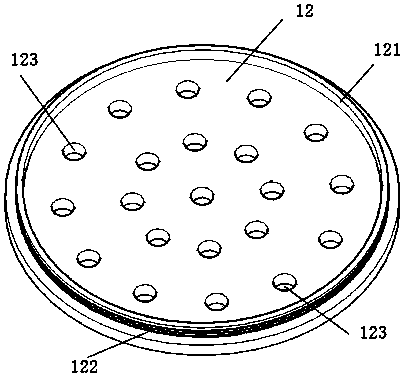

[0084] a. If figure 1 As shown, the assembly of the tunnel drainage device 1 includes connecting the embedded end 111 of the drainage cylinder main body 11 to the base 12 that closes one end of the drainage cylinder main body 11, and the drainage cylinder main body 11 and the base 12 are provided with water-permeable holes 123, Take anti-leakage measures for the tunnel drainage device 1, then pour permeable material into the main body 11 of the drainage tube, and remove the anti-leakage measures after the permeable material is solidified;

[0085] b. If Figure 6 As shown, the rail row 5 is assembled and the track bed steel bars are bound, and the rail 51, the fastener 52 and the sleeper 53 are assembled into an overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com