Cooling structure of engine bearing block

A technology of cooling structure and bearing seat, which is applied in the direction of engine cooling, engine components, bearing components, etc., and can solve the problems of bearing seat structure deformation, lubricating oil cooling effect weakening, gas temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

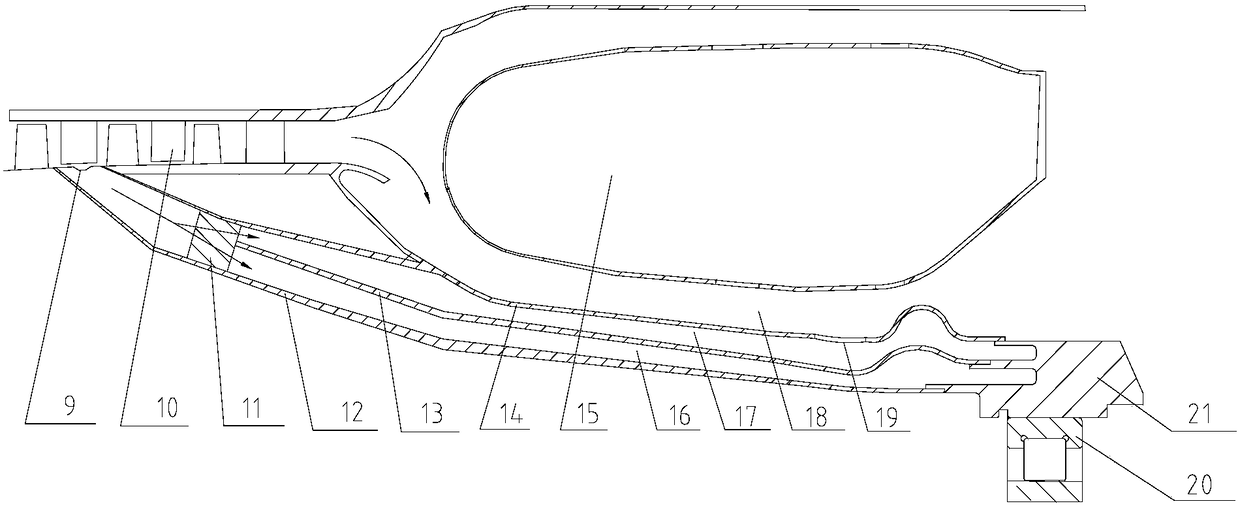

[0021] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The invention proposes a structure that has a better cooling effect on the bearing seat at the hot end part of the engine. By reducing the thermal load of the bearing seat, the vibration of the bearing in the inner cavity of the bearing seat during the engine's working process is reduced, which plays a role in cooling. The purpose of protecting the bearing is to improve the working stability of the engine and prolong the service life of the bearing.

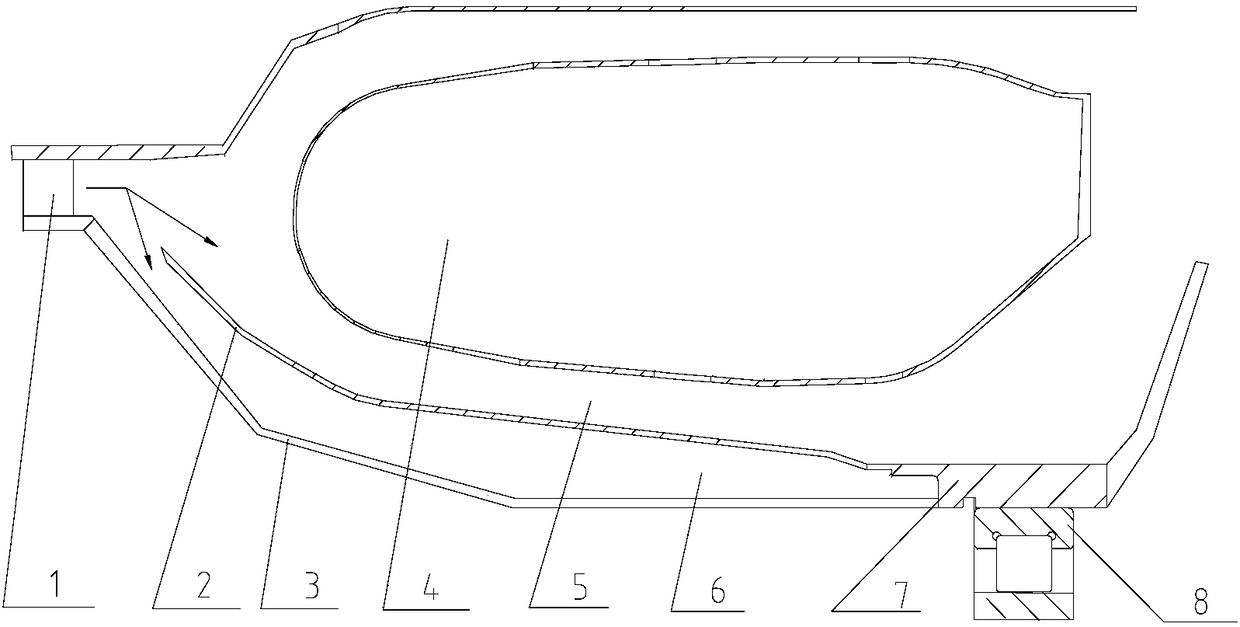

[0023] The engine bearing block cooling structure provided by the present invention is a three-layer annular structure, which includes a support plate 11, an outer partition 12, a middle partition 13, an inner partition 14 and a bearing 20, three The partition form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com