Synthesis method of sodium titanate nanoribbon/titanium carbide nanosheet compound

A synthesis method, titanium carbide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve adverse energy storage device cycle stability and rate performance, weak interaction, poor electron transfer Interface and other issues, to achieve the effect of facilitating electron transfer, fast electron transfer, and improving charge/discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

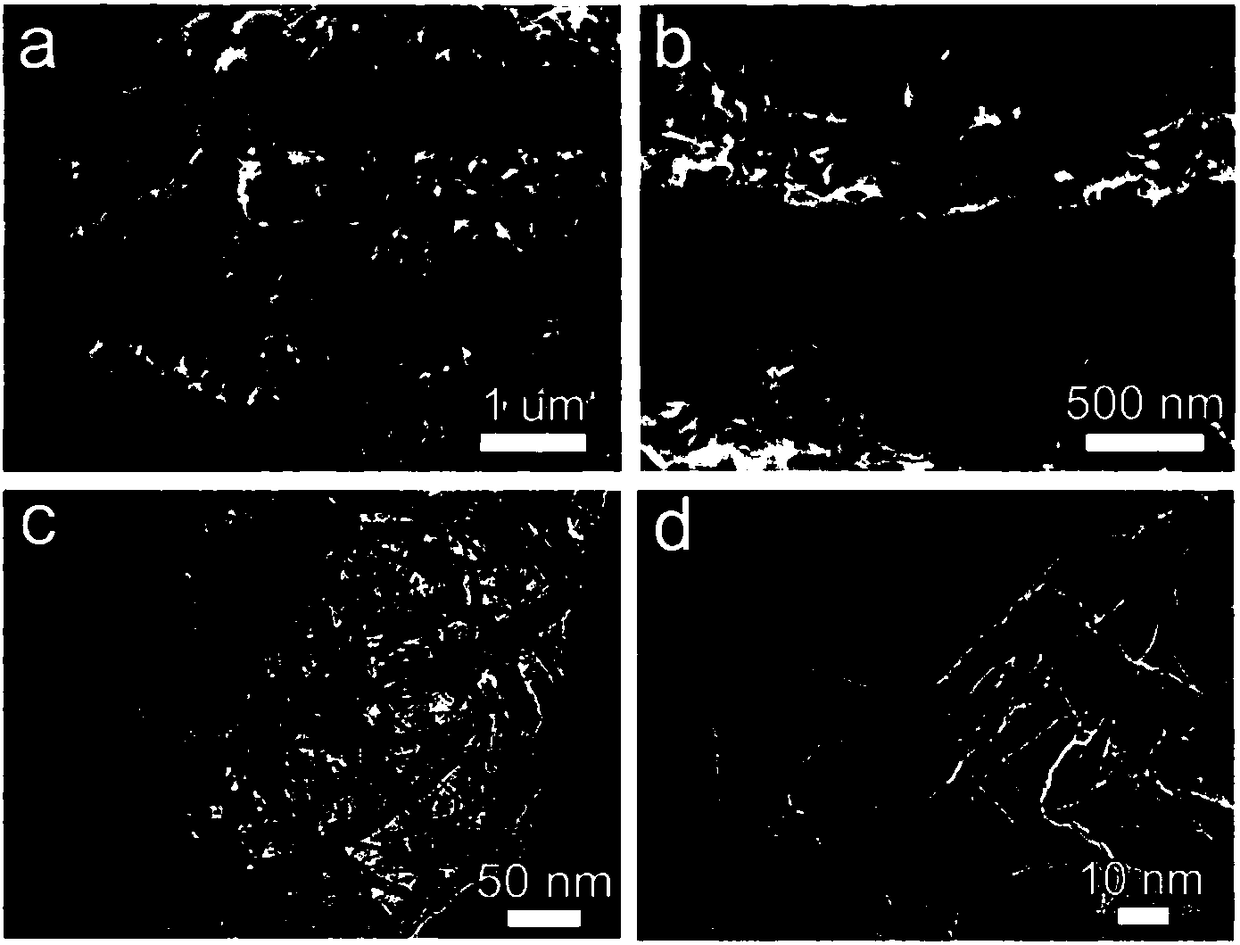

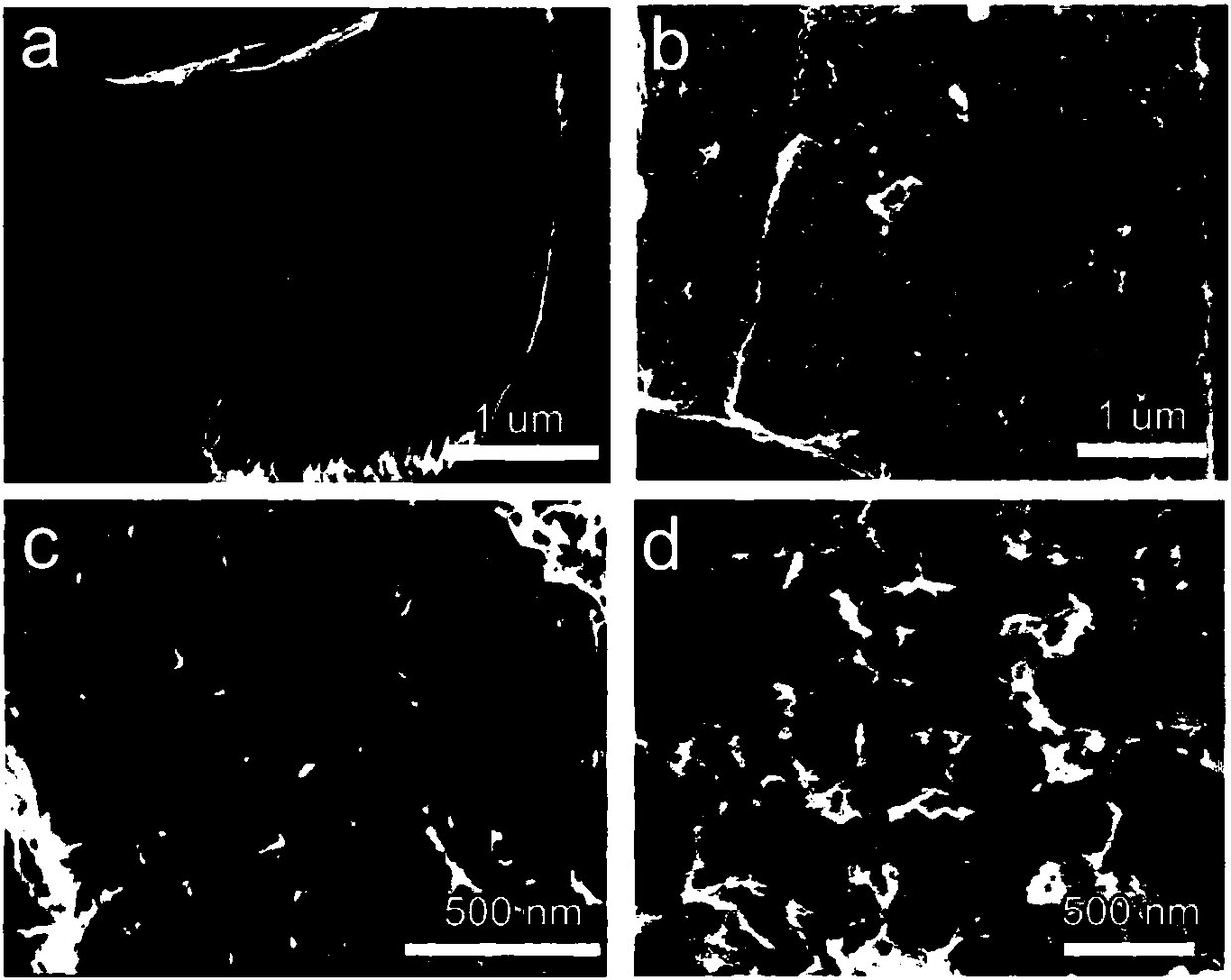

[0021] Add 30ml HF (50%) into the polytetrafluoroethylene reactor, add magneton, 1gTi 3 AlC 2 was added slowly (approximately 5 minutes). The reaction kettle was put into a water bath filled with water, the temperature of the water bath was set at 50° C., and the stirring speed was 550 rpm. The reaction time is 12 hours, the reaction kettle is taken out and cooled, and the samples are washed with water and ethanol respectively until the pH of the washing solution is 6-7, ultrasonicated at 400 watts for half an hour, centrifuged, and dried at room temperature to obtain a two-dimensional layered Ti 3 C 2 . Take 0.2g Ti 3 C 2 Add it to 30 ml of 2 mol / L sodium hydroxide solution, add magnets, and react at room temperature under magnetic stirring. After reacting for 100 hours, wash, centrifuge, and dry in a vacuum oven at 60°C to obtain the product.

Embodiment 2

[0023] Add 30ml HF (50%) into the polytetrafluoroethylene reactor, add magneton, 1g Ti 3 AlC 2was added slowly (approximately 5 minutes). The reaction kettle was put into a water bath filled with water, the temperature of the water bath was set at 50° C., and the stirring speed was 550 rpm. The reaction time is 24 hours. Take out the reaction kettle to cool down, wash the sample with ethanol and water respectively until the pH of the washing solution is 6-7, sonicate for half an hour at 400 watts, centrifuge, and dry at room temperature to obtain a two-dimensional layered Ti 3 C 2 . Take 0.2g Ti 3 C 2 Add it to 30 ml of 2 mol / L sodium hydroxide solution, add magnets, and react at room temperature under magnetic stirring. After reacting for 120 hours, wash, centrifuge, and dry in a vacuum oven at 60°C to obtain the product.

Embodiment 3

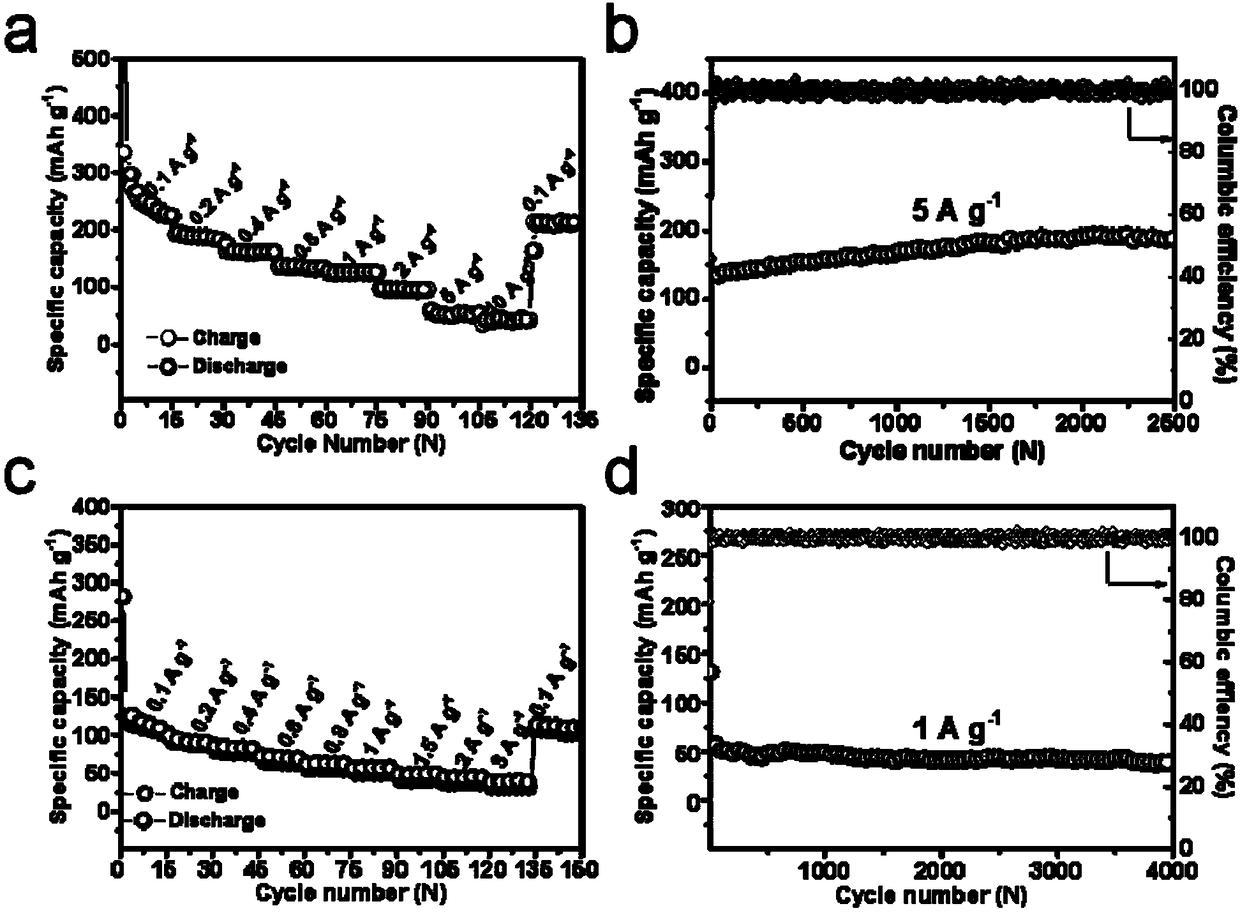

[0025] Add 30ml HF (50%) into the polytetrafluoroethylene reactor, add magneton, 1g Ti 3 AlC 2 was added slowly (approximately 5 minutes). The reaction kettle was put into a water bath filled with water, the temperature of the water bath was set at 50° C., and the stirring speed was 550 rpm. The reaction time is 24 hours, take out the reaction kettle to cool, wash the sample with ethanol and water respectively until the pH of the washing solution is 6-7, sonicate for half an hour at 400 watts, centrifuge, and dry at room temperature to obtain a two-dimensional layered Ti3C2 . Take 0.2g Ti 3 C 2 Add it to 30 ml of 2 mol / L sodium hydroxide solution, add magnets, and react at room temperature under magnetic stirring. After reacting for 10 hours, wash, centrifuge, and dry in a vacuum oven at 60°C to obtain the product. image 3 Prepare Na for this embodiment 0.23 TiO 2 / Ti 3 C 2 Electrochemical properties of the composites as anode materials for lithium-ion batteries and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com