Flushable device for measuring through-flow processes of fluids

A fluid and flow-through technology, which is applied in the direction of measuring devices, measuring flow/mass flow, volume change compensation/correction devices, etc., can solve problems such as gas blockage discharge, measurement errors, and problems, and achieve the effect of avoiding dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

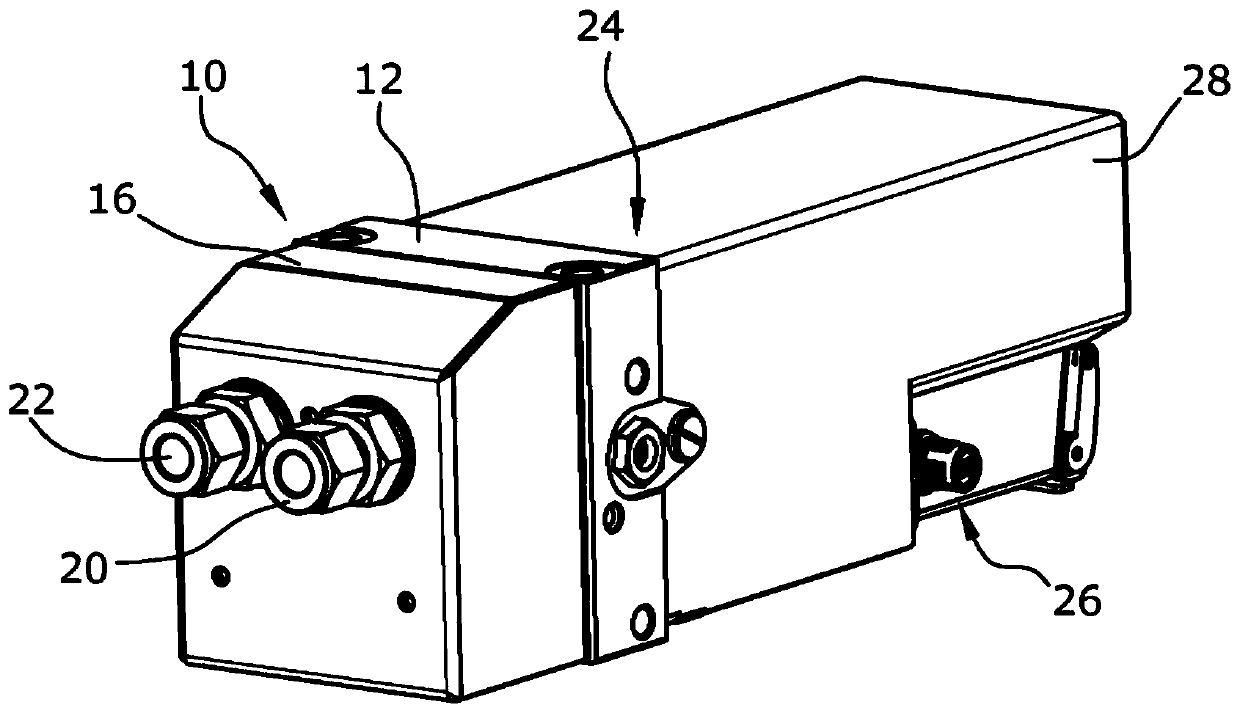

[0040] figure 1 A device according to the invention for measuring a time-resolved throughflow process is shown in . The device according to the invention has a housing 10 made of two parts, wherein a displacement flow meter 14 is arranged on a first housing part serving as a volume housing 12 and a second housing part serving as a piston housing 16 A differential pressure recorder 18 is arranged on the two housing parts. In addition, an inlet 20 and an outlet 22 are formed on the piston housing 16 . The drive unit 24 and the evaluation and control unit 26 of the positive displacement flowmeter 14 are arranged inside a housing 28 which is likewise fastened to the volume housing 12 like the piston housing 16 .

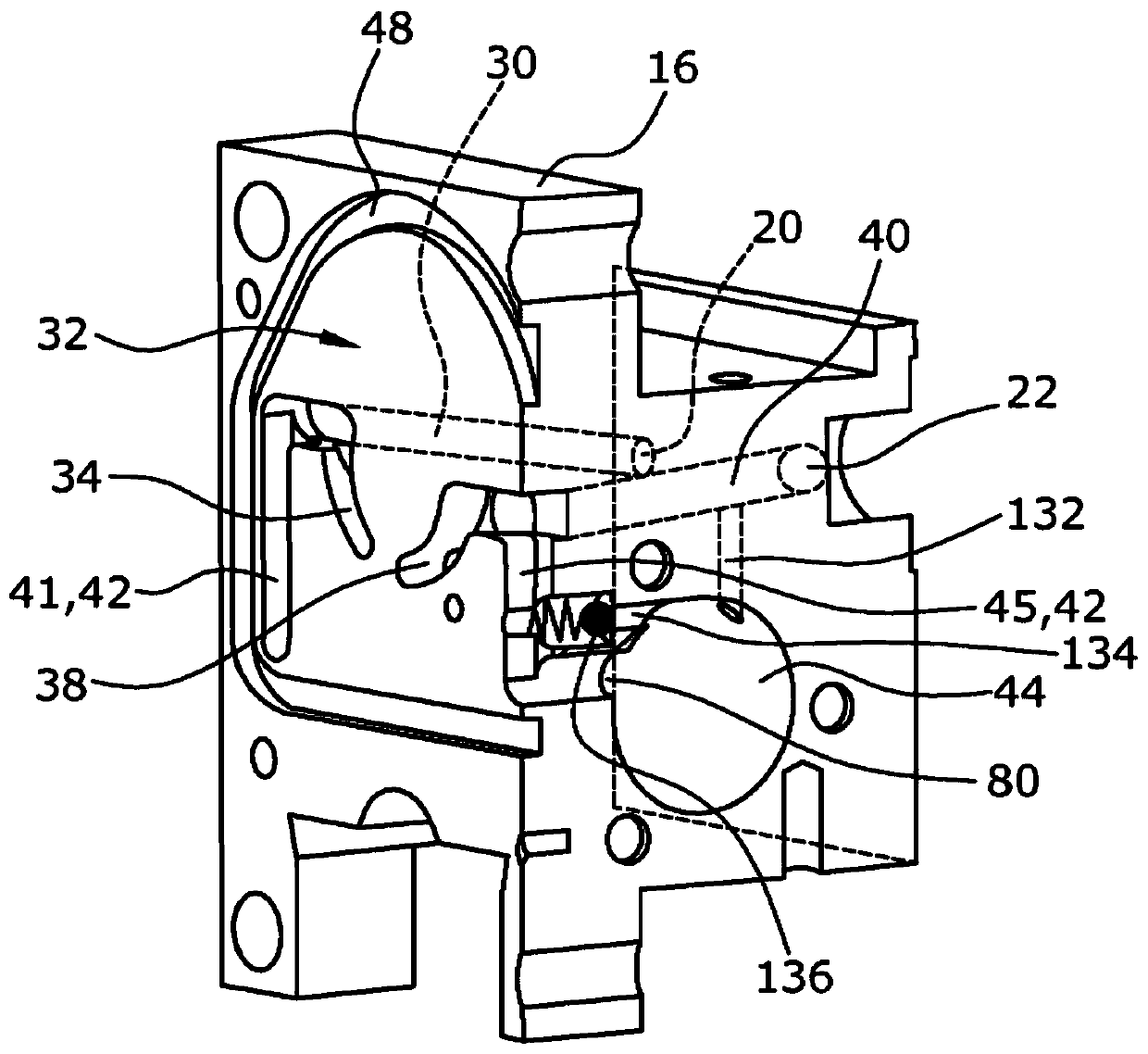

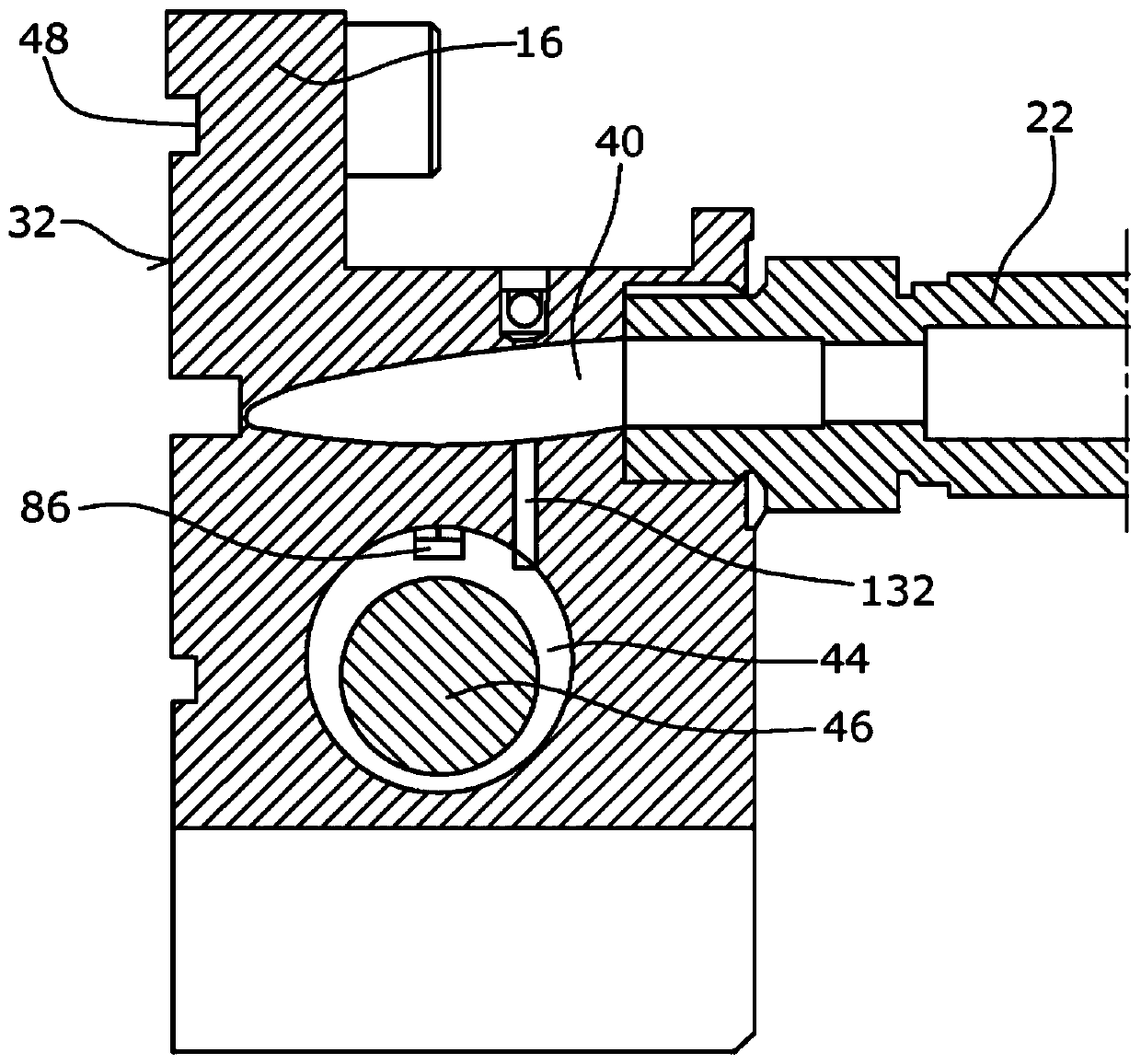

[0041] figure 2 Piston housing 16 is shown in . Fuel flows via the inlet 20 into an inlet channel 30 , which extends through the piston housing 16 to a wall 32 delimiting the end side of the piston housing 16 . Several further channels are milled into the wall 32 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com